Didn't get any pictures of the assembly process, but you can think of it a bit like stitch and glue boat building. I looped a piece of wire through each pair of holes. As I connected adjacent pairs, the mask pulled itself in to the right 3D shape. It was a bit of a pain to get all together, but I found keeping the loops tight and using tape hinges to constraint the orientation of each panel helped a lot. Once it was all together, I soldered everything in place.

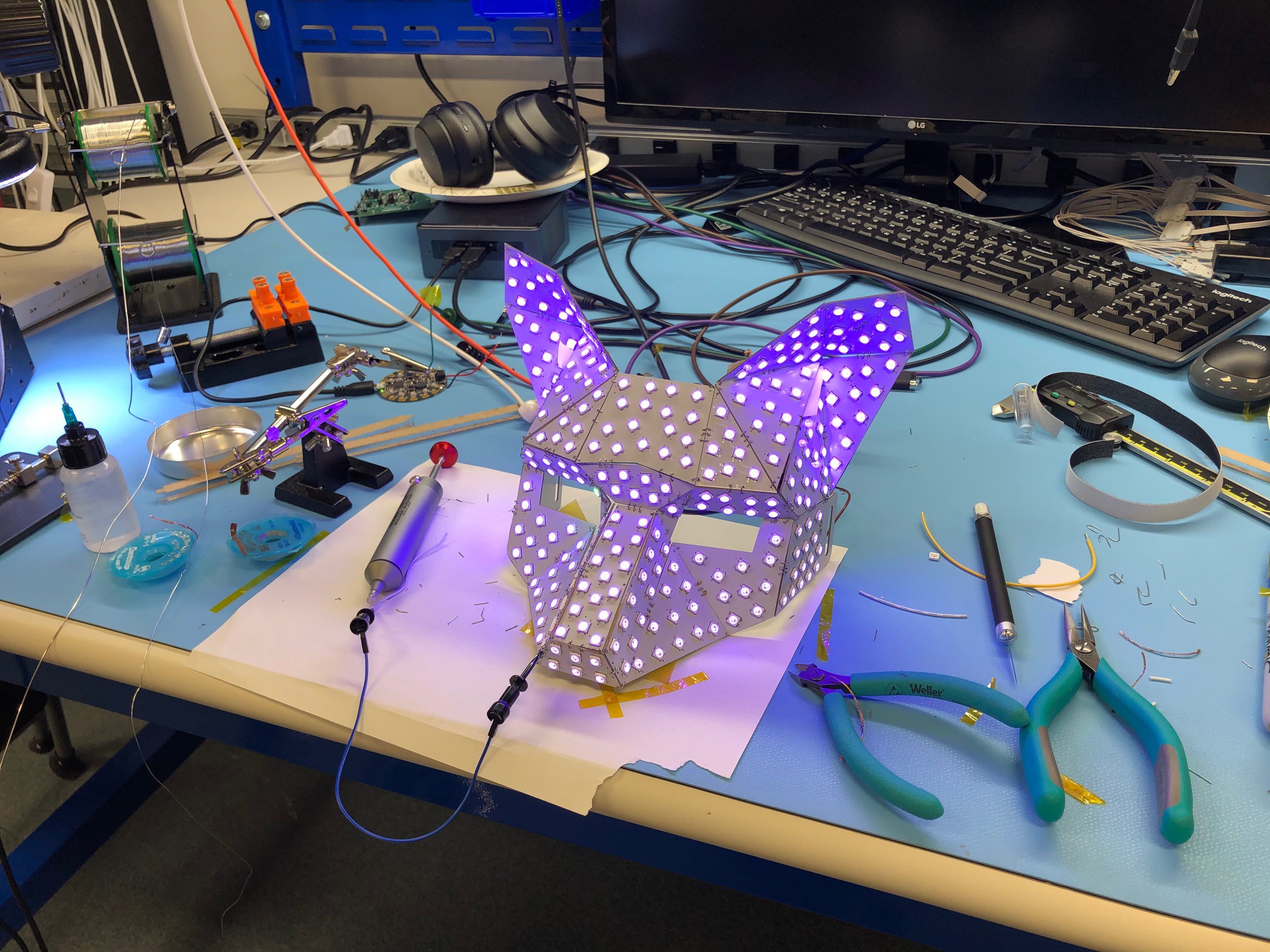

Of course there was a short and I had to go through the rather fun debugging exercise of performing a hardware binary search to see which edge was causing it. Turns out I had flipped one of the most symmetrical panels. Since everything else was locked in place it was fairly easy to cut out the offender and solder it back in the right when. Once I was able to get this picture:

I epoxied over each edge with helped a lot for structural support. I also added some stick on foam to make it tolerable to actually wear.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.