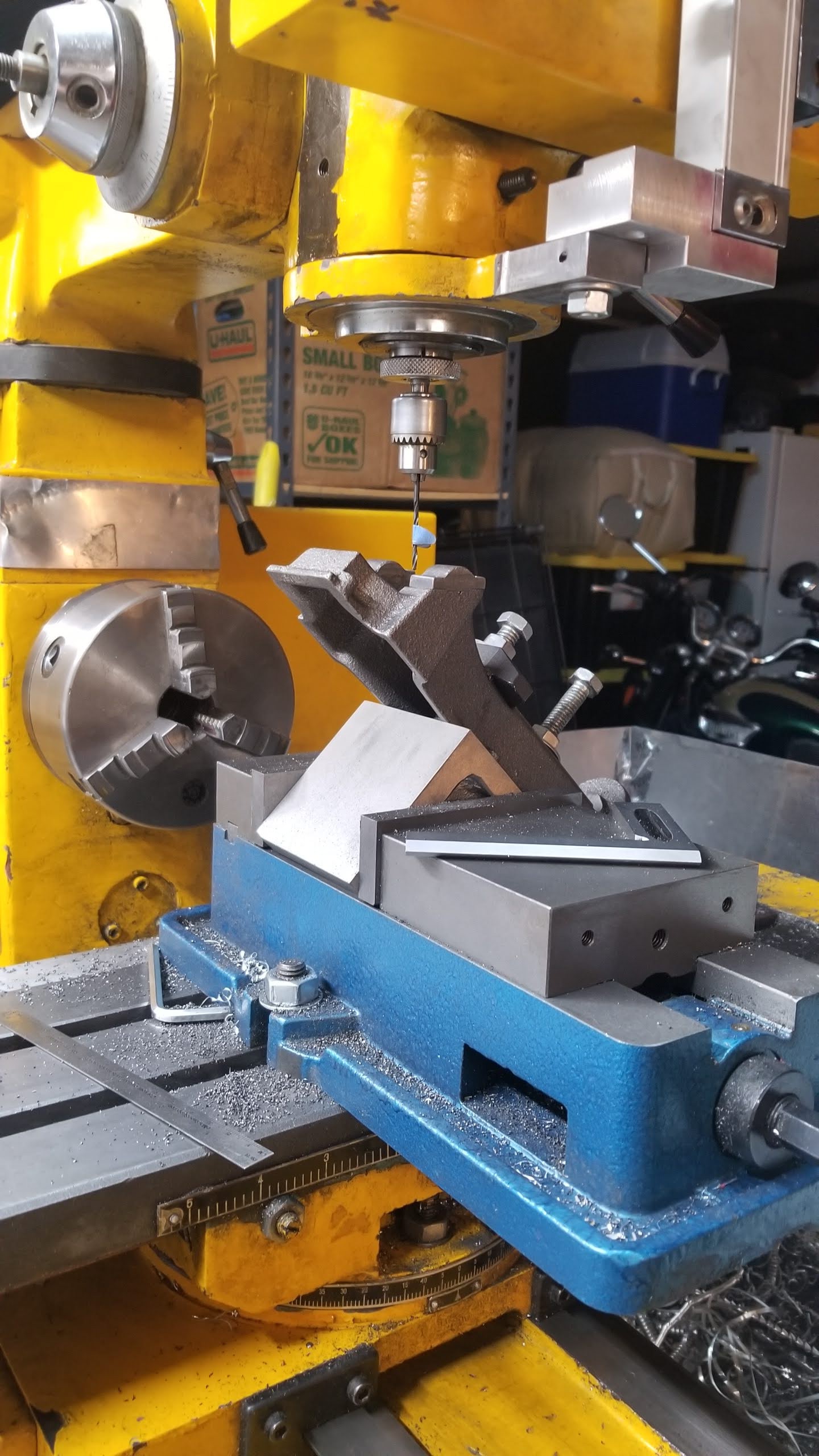

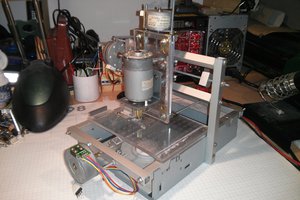

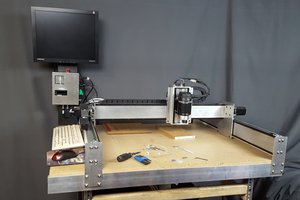

The 3-in-1 lathe/mill/drill form factor is necessarily a compromise. You can't just set up a job on the mill, switch to the lathe and back again like you can on separate machines. Depending on how it is implemented you also run into space issues and rigidity problems. Also these machines are aimed primarily at the hobbyist on a budget and made in China, so quality is variable.

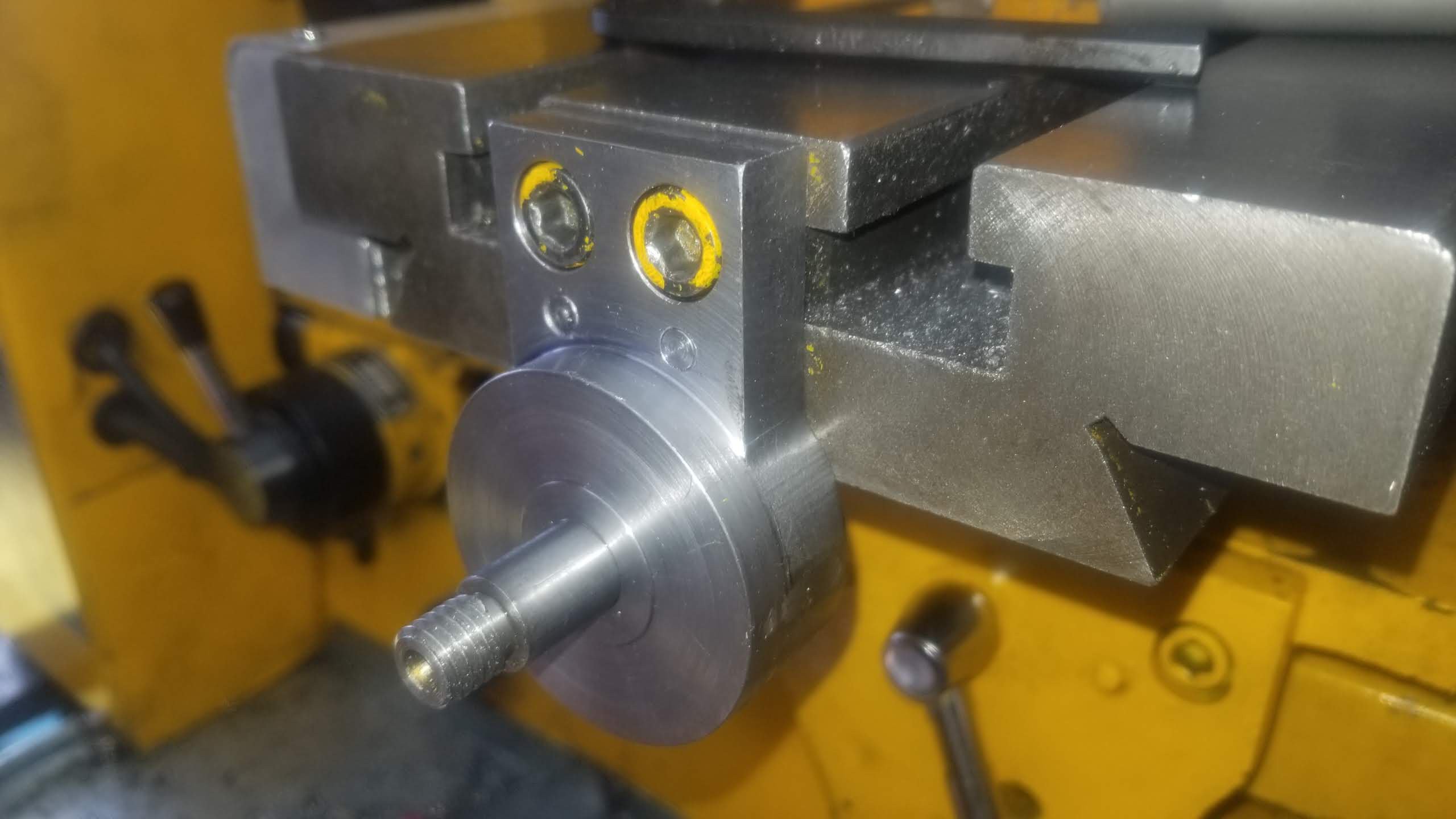

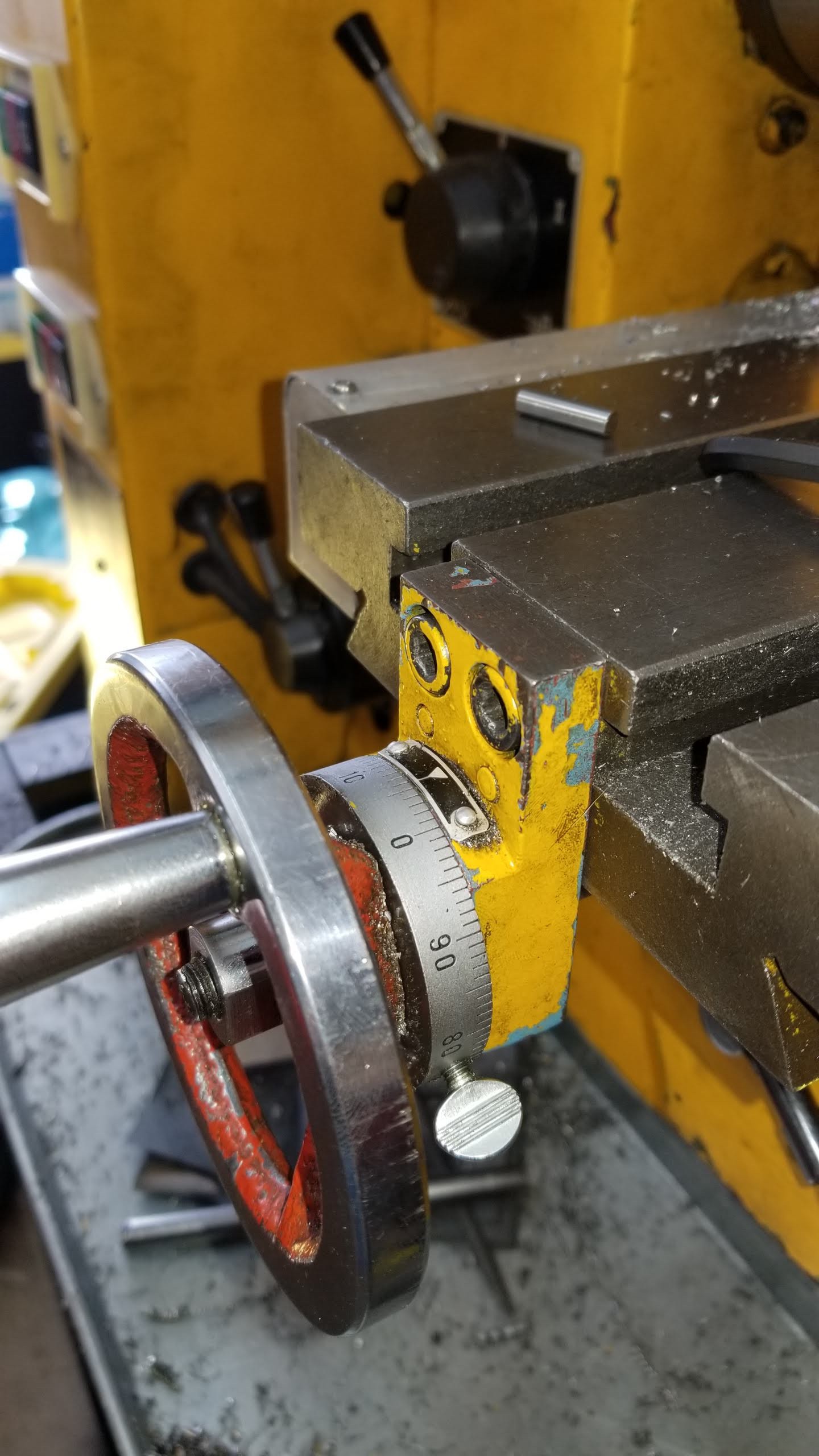

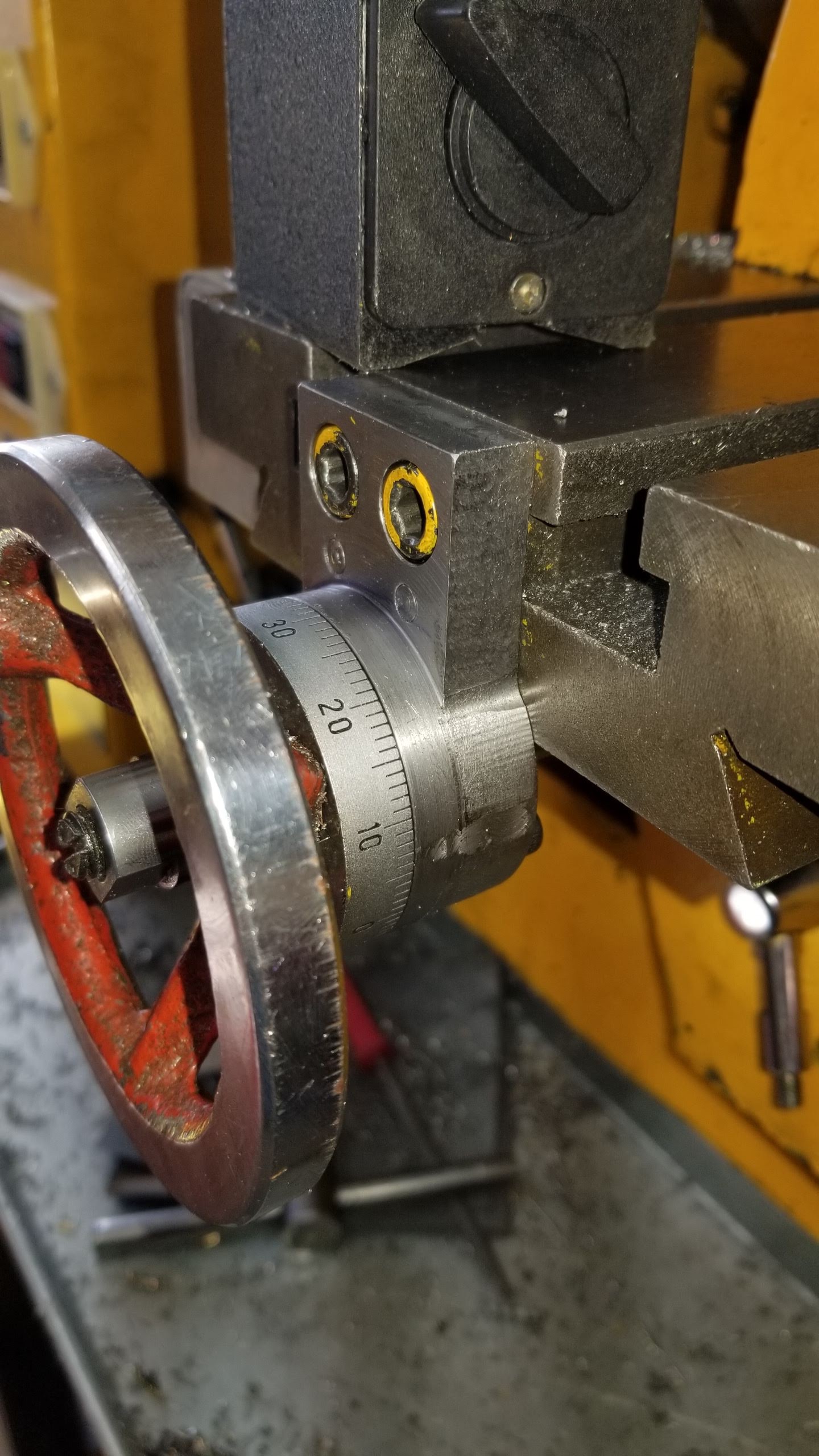

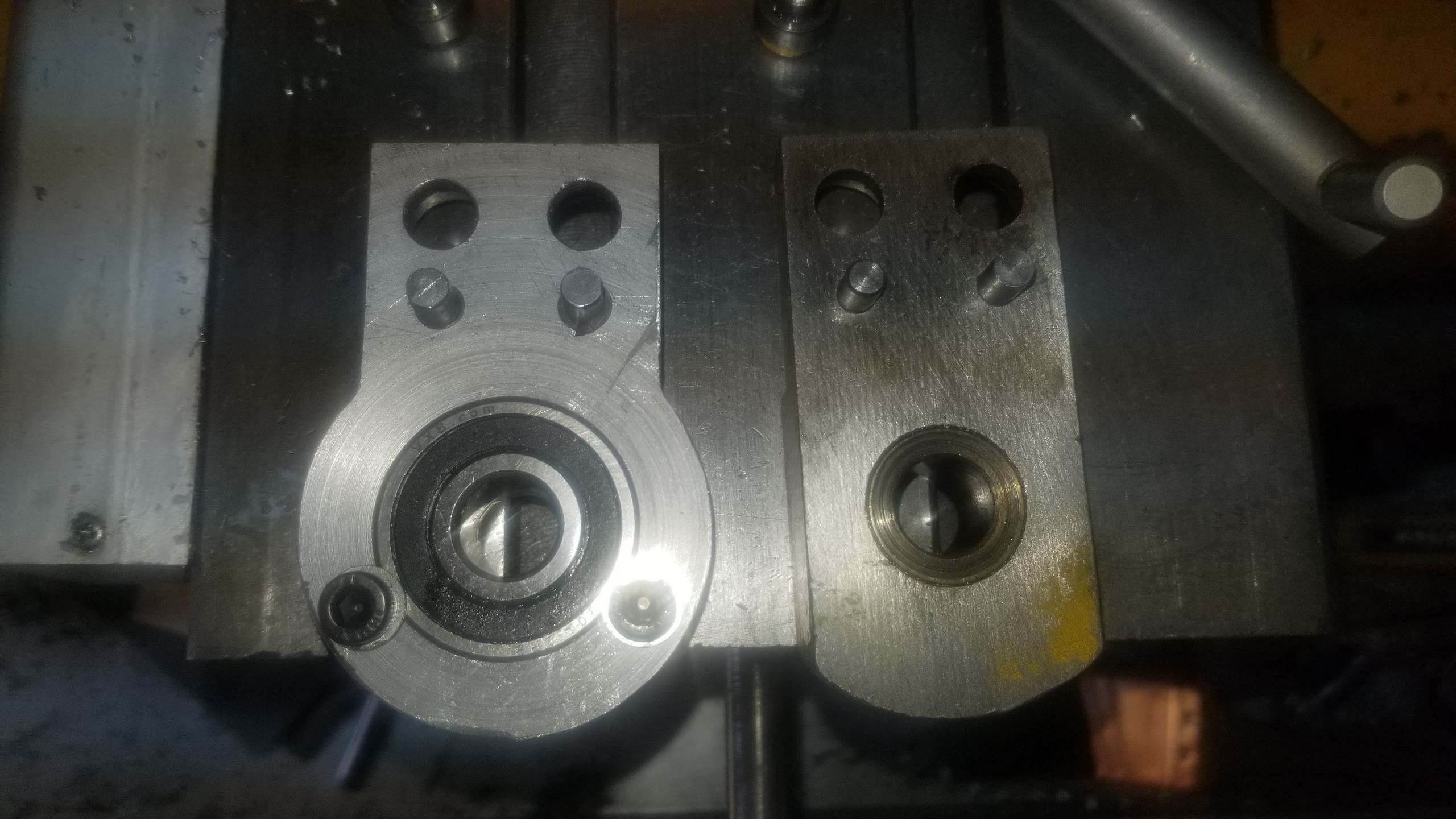

The Shoptask 1720 XMTC Gold (1998) differed from its competitors at the time in that is was aimed towards CNC while retaining the major features of manual use. Shoptask are still around at shopmasterusa.com (now seems to be chicagolathe.com) and they are still making the descendant of my machine - the Mill Turn 2019. This is now a dedicated CNC system without the manual controls. My machine came with the mountings for CNC components, the first design iteration, with the CNC components themselves as optional add-ons - which at the time were beyond my budget. So what I ended up with was a manual machine with a design compromised to aid CNC use - without the CNC. Also with some other quirks related to Shoptask's forward thinking.

Rolling forward to 2020 - at least two of the competitors to Shoptask are still selling roughly equivalent machines - without the CNC options or compromises. These are the Smithy Midas and the Grizzly G9729 . (note that the current Grizzly G4015Z appears from the pictures to be exactly the same as the earlier Shoptask 17-20 BB 1985 – 1988.) There are some minor design differences between these machines, but the overall layout is the same:

- Separate 3/4 HP s-phase motors for lathe and mill

- Mill quill suspended over lathe bed via long unsupported beam

- Lathe spindle high over ways

- no gearbox - swap gears to change lead screw feed for threading

- pulley belt changes to change spindle speeds

- no mill knee - mill quill only. Shoptask only has 3-1/8" travel (Smithy has 3-5/8" and the head raises "40%", Grizzly has 4-5/16")

- fine and gross feeds for mill (gross = drill)

- mill table acts as cross-slide

Smithy also have a beefier machine - the Granite - with 2HP variable DC motor and a quick change gearbox and a 4-7/8" quill travel (and the whole head can be raised another "30%"). If I were not fixated on having CNC and manual use on my machine, I'd probably upgrade to one of those, rather than fixing up my Shoptask.

The Shoptask differs in two major ways from these other 3-in-1 designs

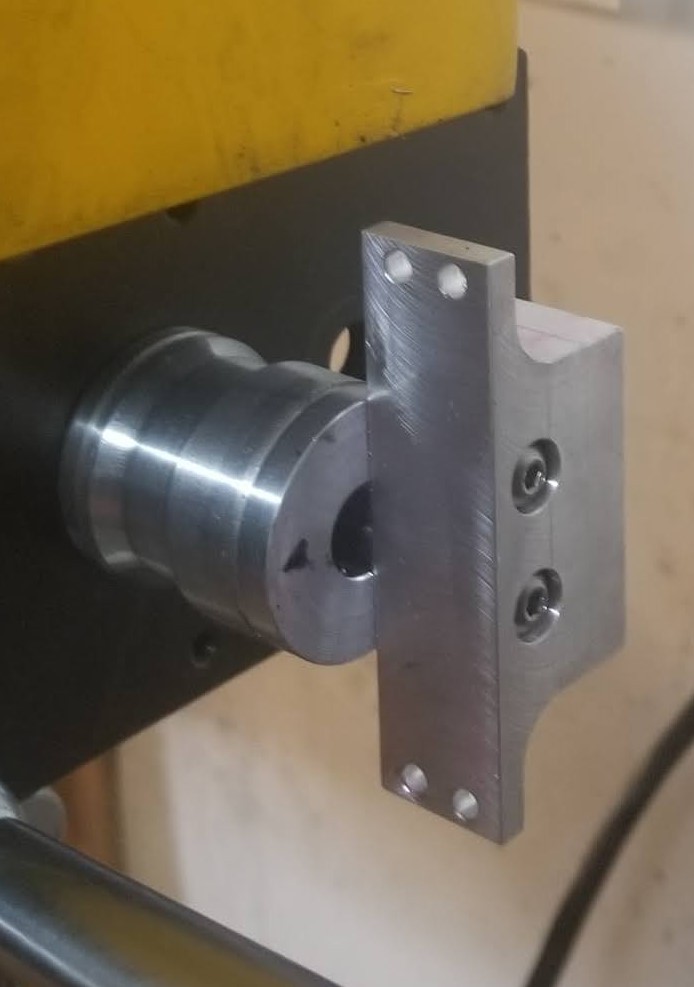

- The traditional half-nut and threading dial are not there. The lead screw nut is solid bronze. This makes manual threading a challenge but is a logical step for CNC.

- This also means there is no fast feed handle on the apron, as those need a disengaged half-nut.

- There is no compound and top slide. Because that would be handled by CNC? Instead the whole table/cross-slide rotates. A bit. Not a lot - its too big. Which means every time you rotate it you have to indicate it square again.

Things to do - General

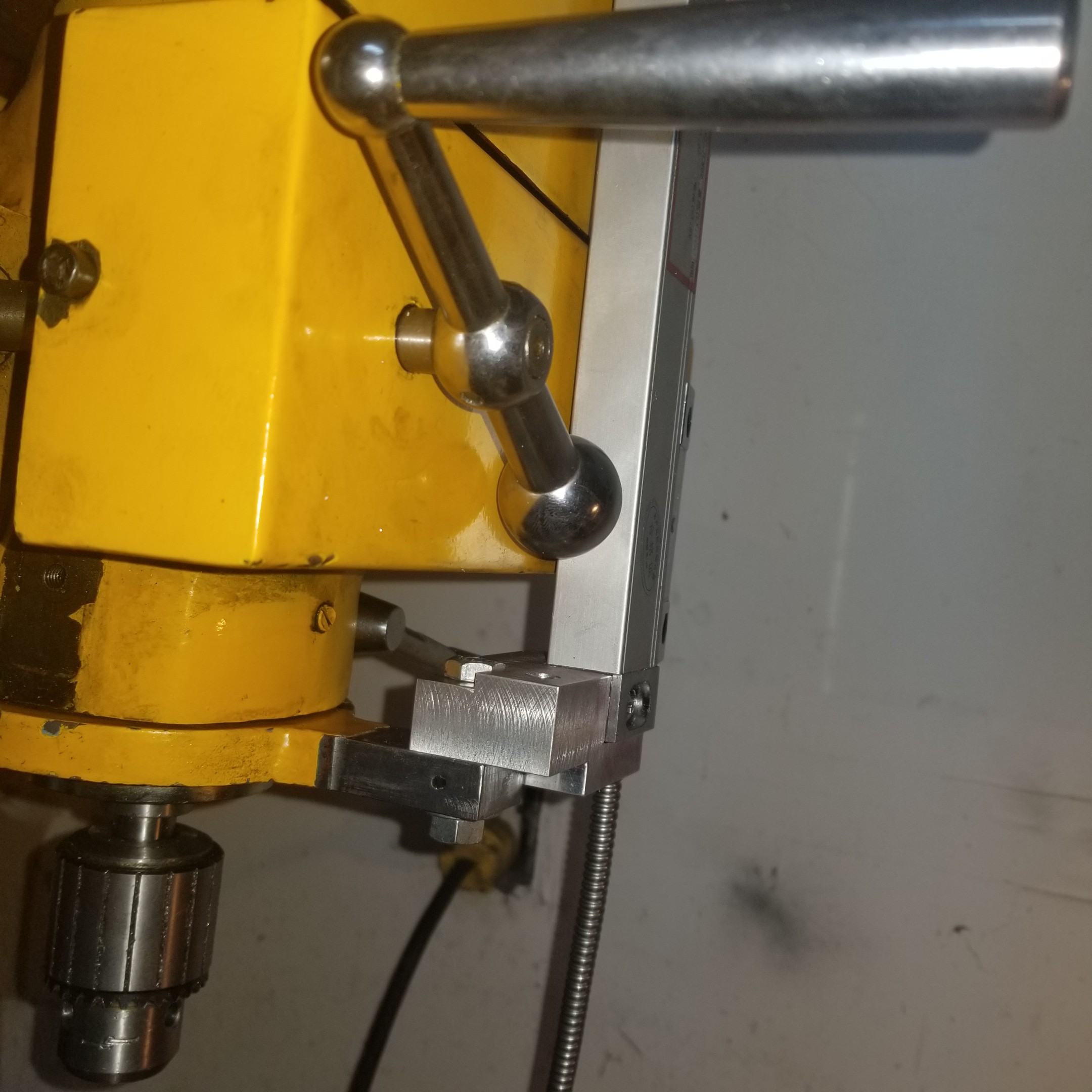

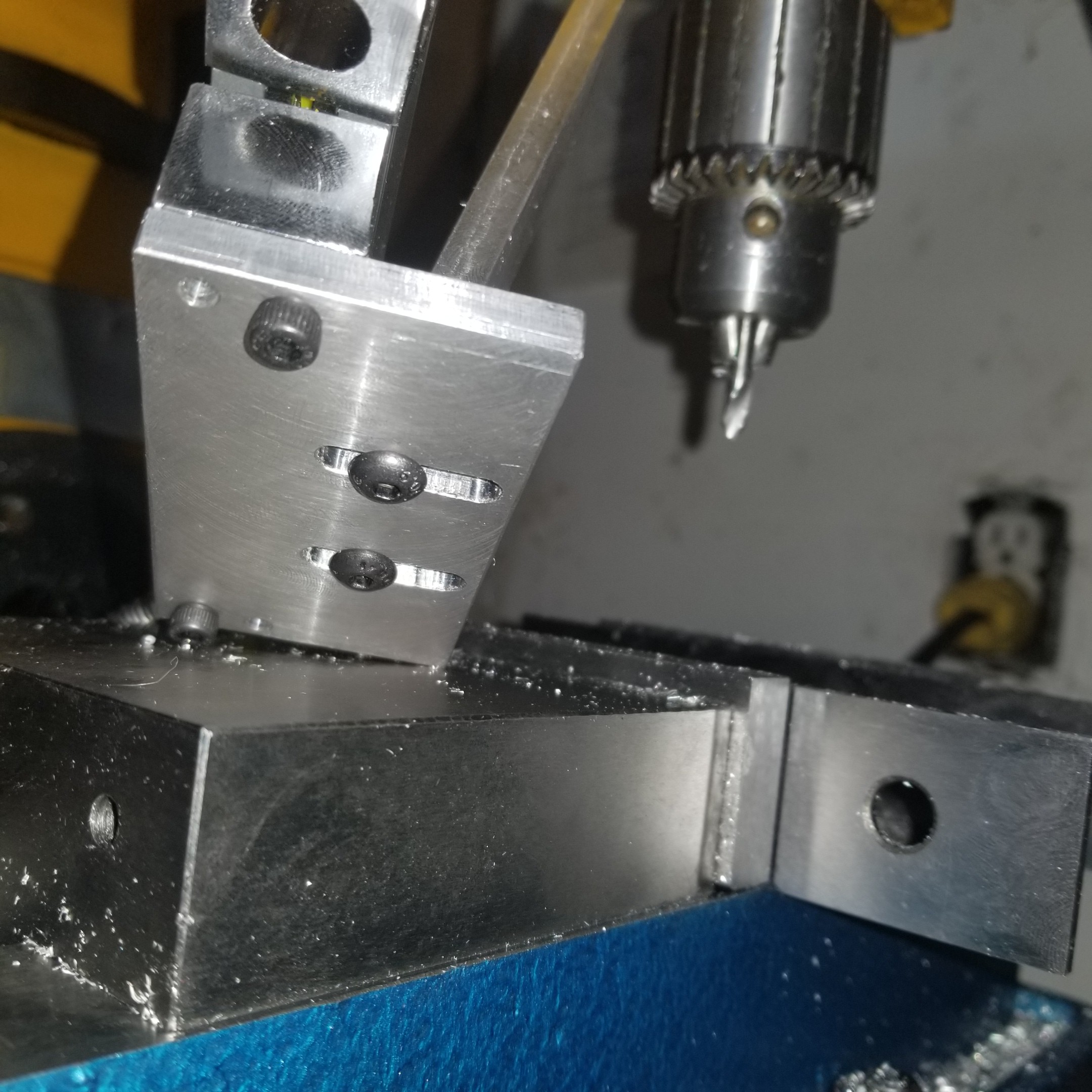

- Install 3-axis DRO. Its 2020 for chrissakes. MOSTLY DONE. X-Y-Z done! See logs.

- Make a splash guard and drip tray. I have been using a modified plastic storage bin for a tray that was almost the right size but it has seen better days - and it's a pain to access to fish out dropped things. I have no splash guard - the motor ends up buried in chips and a lot of chips end up on the floor. DONE - https://hackaday.io/project/173386-shoptask-1720-xmtc-stand-upgrades

- Coolant feed/cycle - DONE Kool Mist I bought in 1998 installed

- chuck key holders.

- Bolt up the cross-slide dead-square and never rotate it again. DONE - but it still moves. Re-check when I mount the vise.

- Tool box under the table - DONE https://hackaday.io/project/173386-shoptask-1720-xmtc-stand-upgrades

- retractable wheels - DONE no wheels, use dollies as needed

- floor bolts.

Things to do - Lathe

- deferred maintenance.

- Gearbox oil change - overdue. DONE

- Spindle bearings - open and inspect and grease. If not both OK and Name Brand, replace with new Timken. These...

Alastair Young

Alastair Young

Stefan Lochbrunner

Stefan Lochbrunner

Caleb Peters

Caleb Peters

gregstephenson

gregstephenson

Hello, I have recently acquired a shoptask 17-20 xmtc as well, I am slowly restoring as it has been sitting in a shed for 15 years without use. I was disappointed to find the piece was without the tail stock makes using the lathe portion rather difficult. I have been looking for parts without success, I would love to know if you have run across any