I've started work on the Y axis DRO mounts, using Fortal alloy (7075 T-651 from ebay seller scottkrez). This is a material I have used before and I know it machines well and can be made very shiny.

I'm on a learning curve with Fusion 360 and I'm on a relearning curve with the milling machine. The last time I used it in anger there were a lot less youtube channels on machining and I was doing a lot of things wrong. There are also some tricks for the Shoptask which I had forgotten. For instance my biggest mill is a 5/8" for which I purchased a 5/8" MT3 collet so it could mount up close to the head or in the 4" MT3 extension. What I forgot was that I really need a stop in the collet or the mill creep up in the collet vertically under heavier cuts. Properly tightening the mill column and the drawbar are also Good Things.

After some trial and error I have the piece down to 35mm in one dimension. The other dimension as to come down to 25mm from the current ~35mm. Lengthways was cut on the 4x6 bandsaw so that dimension does not need much taken off. I may try taking the 9mm of the face of the block with the bandsaw in vertical mode, though that thing is a bit scary.

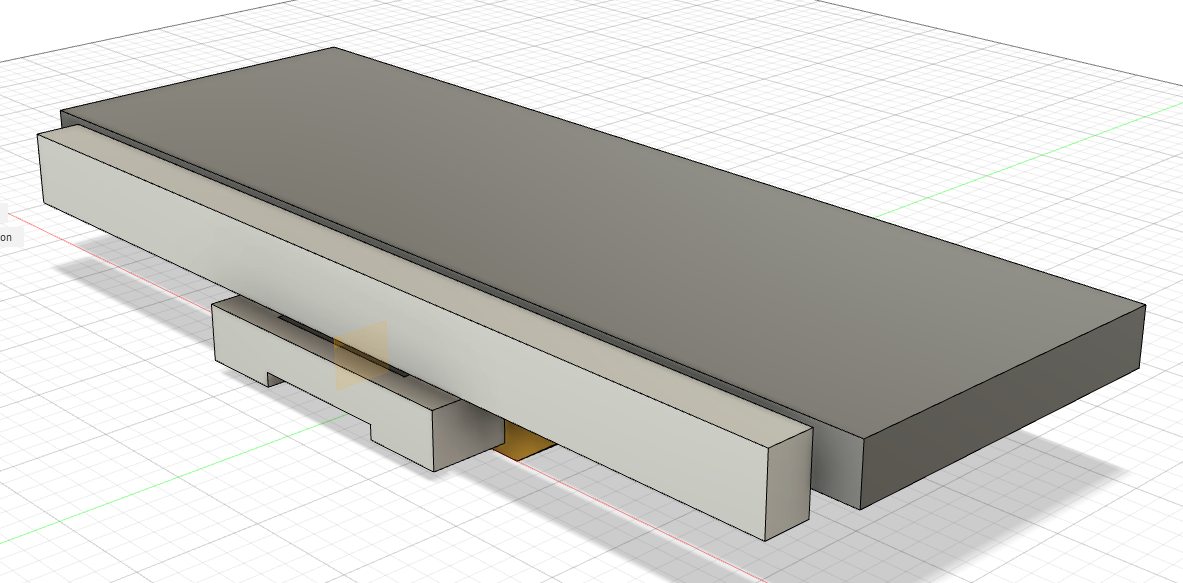

The part I am making will mount to the base of the cross-slide and wrap around the DRO sensor head to use the side mounting screws. I would rather have made it slimmer and support from underneath, but that would block access to one of the nuts that tightens the table rotation. The scale and head will be 2mm out from the base though I may skim that down a bit depending on what material I use to run behind the scale. As the scale overlaps the base somewhat some clearance is needed.

I have ordered some parallels for the vice, as for cutting the channels into the part it will have to sit up high. The first time round with this machine I didn't even know what parallels were and I managed with random stuff. The best I have at the moment is to use dies. As these are ground I was able to find a couple of matching thickness to do the job for now. The vice I have is a tilting angle vise that I bought with the machine that looks very like this: https://www.hhip.com/4-deluxe-tilting-angle-vise-3900-2684.html

This has to be set up on two 1-2-3 blocks on the "2" side to raise it high enough, and setting the tilt to properly horizontal is a pain., and I'm pretty sure it lacks some rigidity.

So the next thing on the shopping list is a 4" mill vise of the Chinesium-Kurt-Knockoff variety, along with the swivel base. I think this will be nice and high and by mounting the swivel base at an angle I should be able to my two (narrowly spaced) T-slots and get it centered on the table the "normal" way round.

Also purchased is a used Starrett S828H wiggler set for $25.

Alastair Young

Alastair Young

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.