Hello guys! long time no see!

First of all, the project is going on. Don't worry.

I've been thinking a lot about how to make robotic joints for a month.

My conclusion is as follows.

: a reliable structure at a moderate price.

In fact, the robot arm has a long history of being built. You can search it as an industrial robot on YouTube, and you can see it very simply from 10 years ago.

For example, KUKA or ABB..

So the various parts of the robot have already been refined, and we just have to buy and use them.

While the way to buy and assemble the product may blur the density of the effort in the project, I thought it would be more appropriate to buy the reliable parts than to make all the parts themselves (2.5-5axis CNC machining) because this project would allow many people to create their own "trustworthy" Open Source Cinema robots.

But because we have to make a firm compromise on the important part of economics, we have decided to move towards the minimum use of these 'well-made' parts.

Although the price of materials is going up more compared to the price of parts originally planned, I am not going to compromise with the price barrier regarding the quality of finished products.

So I decided to use the following parts.

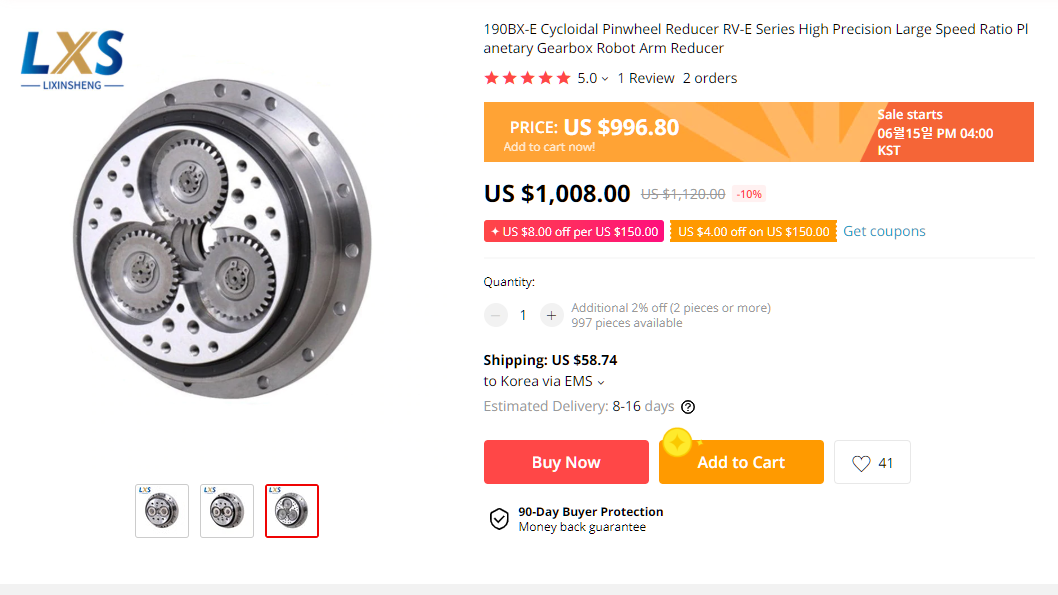

The RV Series reducer.

For Joint 1. (BASE)

RV50C (more than 1,000$)

Because it is a gear that penetrates the main axis of the robot, it is where all the loads are concentrated, and for the robot's smooth rotation, it is decided to use a gear with a crooked hole in the easy-to-pass front, such as a motor cable.

For Joint2.

RV40E (https://www.aliexpress.com/item/32971948911.html?spm=2114.12010612.8148356.1.7be514abTqoICb)

For Joint3.

RV20E(https://www.aliexpress.com/item/32971665771.html?spm=2114.12010612.8148356.5.7be514abJVITQo)

The gearbox of the RV series will only be used for these three joints. Of the total six joints, the remaining three will be either purchased from other parts or manufactured directly through CNC processing.

We have not yet secured a place to purchase parts for the BASE axis, but we will update the information before the project is finished. In my case, I will purchase through a local supplier.

Except for the three axes above, the other three axes will adopt a power transfer method through metal wire control for lightening.(see below video)

This is to inform you that there may be some upward revision for the model number.

Time to go to work!

No jae gun

No jae gun

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.