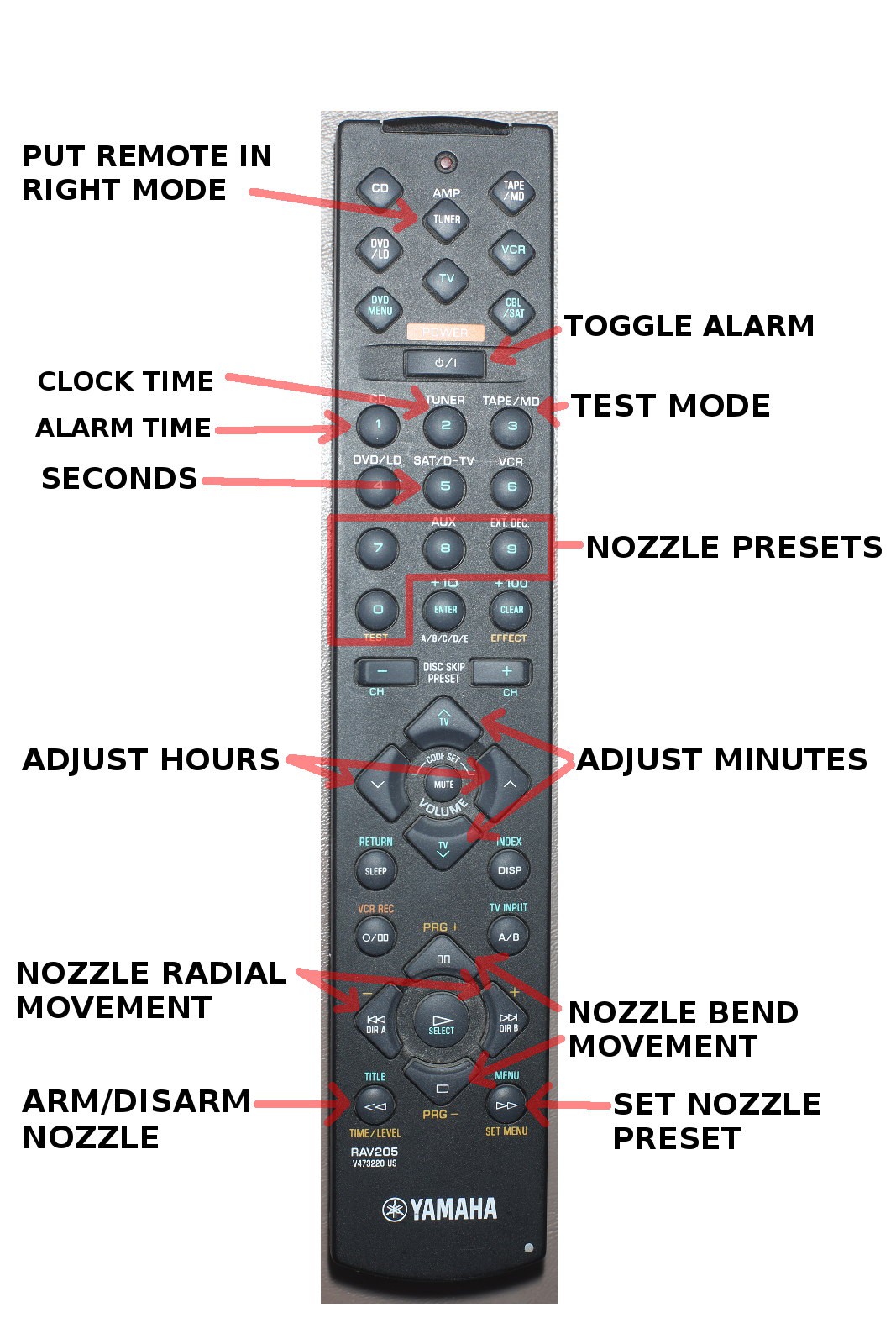

Positioning the nozzle by IR remote has grown into a pain in the mane. It would be money to have 3 preset positions.

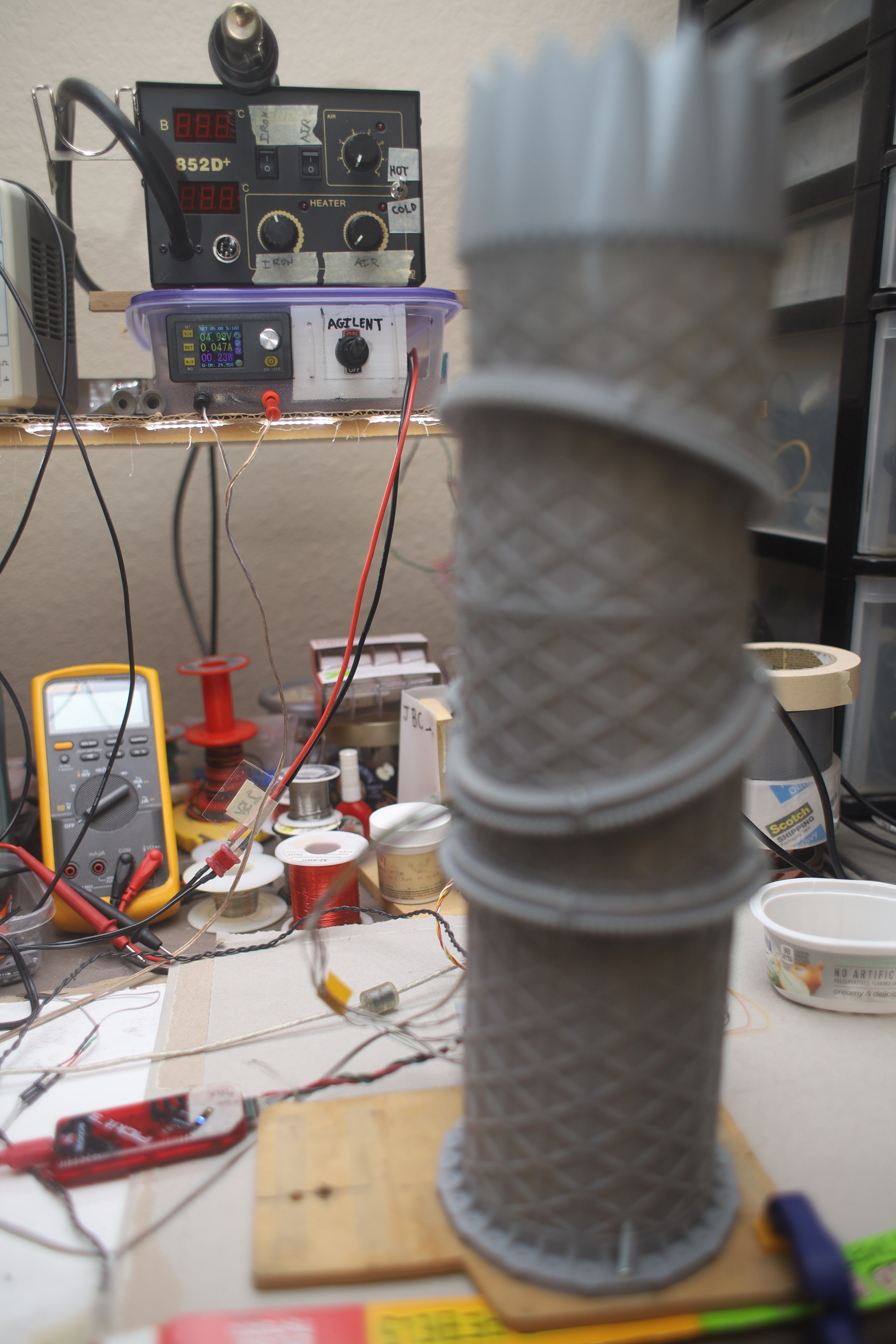

The mane problem with presets was supporting 5 more remote control buttons. The clockspeed had to be stepped up to 22.579 Mhz. This increased the standby current to 50mA. Having it on the bench again brought back the memories of the time it was created.

It's not the most efficient solution. It compares every IR code against 10 values in a table, as soon as it's received. It would probably save 20mA to store every IR code in a FIFO when it's received & process it when the CPU has enough time. The 20mA would just require a lot more programming & no-one ever got quizzed on the power requirement of a software change in a job interview.

The remote control is becoming a beast.

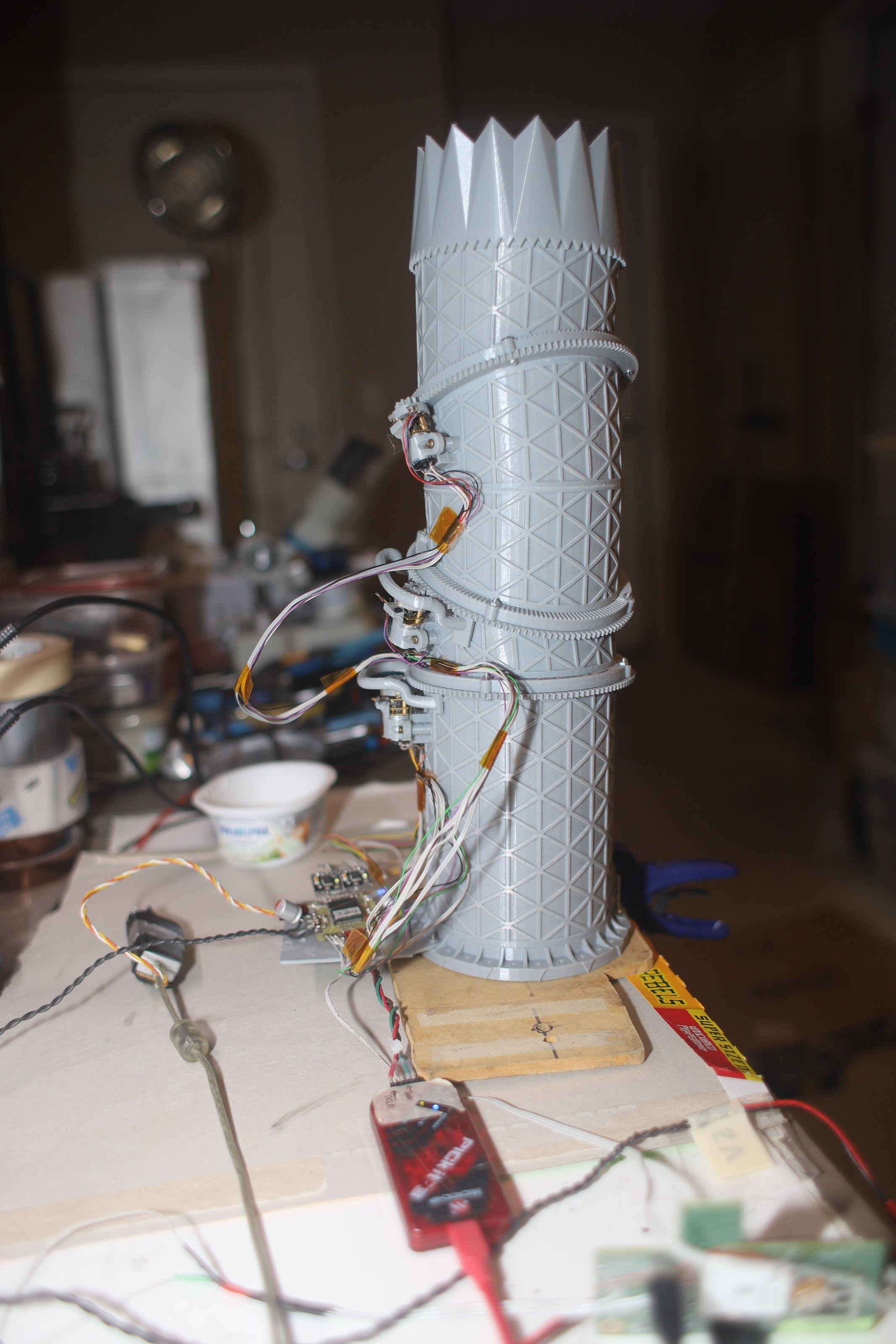

The accuracy of the motors is a pain in the mane. The motors were originally bought for a traction application, not suited for precision. The gear reduction possible with 3D printing is bad. No way to improve the accuracy without new motors presented itself. More accurate motors would be $40. The new motors have integrated encoders, so the boundary switches could be closer to the motors. That would entail printing new motor mounts. The gears would no longer have magnets but would have the same dimensions.

The nozzle could stand to be a hair larger in diameter, maybe 5mm.

There is a slight advantage to printing a new nozzle, buying new H bridges, magnets, & motors.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.