The Beginning

Before I start, I would like to point out that I am not an electrical engineer so am trying to learn how things work as I go with google…. These notes are messy and is likely grammaticlaly concerning and will be fixed at a later date.

The initial plan of the project was to attempt to shoehorn a thin mini itx board into a thinkpad chassis such as the t43 14.1 or 15. The hope was to create a series of board which would allow mini itx thin boards to be swapped out when necessary as a modular board.

Whilst my research process had been all over the place my first pain point was finding out whether or not I could create a method to interface with the existing ThinkPad battery and use it with an thin mini itx board from a thinkcentre m715q or m75q (found later and better).

Concern 1 – Power requirements

M715Q Uses a 65W PSU at 20V, CPU (35W TDP), this seems within reason to deliver from battery with a dc to dc step up.

Unsure whether the 20V input is actually more flexible than described to minimize creation of new power delivery adaption boards. (from what I know [not entirely sure if correct] laptops often have power delivery built onto the system board which is powered directly from the battery with a flexible dc power conversion). Similarly, as a laptops working components typically operate at 12V and below which raised concerns for me about power wastage from stepping up and then stepping down wasting extra power.

Concern 2 - SMBUS Smart Battery Interfacing

I wanted to ensure that if used the laptop would be able to operate using a battery with the voltages and communication happening as they should with Windows. I learnt about the smart battery which connects to the smbus to communicate with the computer. At this point I was concern I had imaged that maybe this feature would be locked in the bios or manufacturer specific and would not just work with any motherboard for communications. I then found that any computer with an smbus reserves the battery addresses (i2c / smbus) for communication, which would be potentially something which could simply be connected. This led me to find out how I would be able to access the smbus data and clock lines to add the said battery. I found some motherboards have this just on it. But I could not find anywhere obvious to find it on pictures of the m715q motherboard, as I dug further into the problem as found on hackaday I learnt that the smbus pins are within pci-e and ram slots which led to the potential for interfacing by some modification of adding wires toa sodimm ram module. With this I was scared to potentially damage a board especially with the limited budget of the project / me. Whilst I believed that could potentially work I am working to avoid as much of this as possible (until the project develops further).

Concern 3 – Cooling

A large part of laptops and similar small devices is the requirements for cooling in a small area. Whilst I will use some thermal simulations later I found that many of the thinkpads, used cooling systems which looked possible to modify at some to reroute heat in the laptop chassis. Typically the ultra low clearance of the motherboard assembly requires some form of flat heatsink on the cpu and chipset and heatpipes to transfer heat to a fan and radiator assembly. As I discovered in the t43 chassis simple heatsink design could be made at home with some thin copper sheets (1-2mm) which are easy to cut and I could desolder and resolder heatpipes from different devices until it fits.

Concern 4 – Display interfacing / swapping

For me one of the main issues with the older ThinkPads is the displays when compared to modern devices. They are just not as bright or high enough resolution and lack things like touch. What they do have is 4:3 ratio which for me feels far easier to work on then a 16:9 display of similar diagonal size. Whilst modders have been swapping CCFL tubes for led strips to convert their devices to use LEDs backlights with higher brightness and lower power, this does improve colour depth and / or resolution. The older devices commonly used the internal LVDS interface to the motherboard, which has been more or less changed for eDP in more modern laptops which uses less lanes for the same resolution and the possibility for high resolution and touch interfacing to be on a single cable.

Looking back at the thinitx board it did not have a purpose built internal display connector like some of the other thin itx boards for “industrial use”. I wantd to find whether a displayport could be interfaced passively with the internal EDP of modern lcd pc panels which it is based on as there was a display connector “extension” connector which could support hdmi, vga or displayport. I imagine that one way or another this would work, even with power being required to be added somehow.

The alternative methods for interfacing include using universal LCD driver boards which convert the LVDS, eDP or even MIPI (used more in mobile devices) signal into HDMI, VGA or DisplayPort. Whilst useful, where possible we wanted to avoid adding extra boards if possible. These will also have onboard buttons for changing setting and inputs etc. Some of these could be remapped to be activated using an internal microcontroller (saving the space of another external board) and a bit of custom software.

Concern 5 – Maybe it’s ok?

At this point whilst many of these options seem potential viable they do carry a fair bit of risk with multiple systems being potentially required to enable simple functionality with the possibility of terrible battery life.

Any version of this project would require Frank Adam's (https://www.instructables.com/id/How-to-Make-a-USB-Laptop-Keyboard-Controller/) which was covered by Tom Nardi of Hackaday (https://hackaday.com/2018/12/04/teensy-liberates-the-thinkpad-keyboard/), work on interfacing with the thinkpad keyboards and trackpoint with a teensy to allow it to connect to usb, or ps/2 if header is available with a custom board. Interrfacng with older thinkpad trackpad use ps/2 connectors for the trackpads this enabling near immediate functionality (note 1).

The forced version of the project could use a lcd edp control board (with own voltage conversion from battery at least), secondly a step up power delivery board for the battery to supply the 20v input of the motherboard. An internal i2c board would be required to read battery voltages outside of the Window AHCP system if I cannot use the smbus smart battery system

I don’t believe using the old trackpad is good solution if actaully planning to use it as ideally a trackpad would be switched out to allow a larger surface and better tracking using windows precision drivers. As far as I’m aware modern touchpads in laptops can connect to windows as an HID using the SMBUS or USB (rarer). Again there is the concern of overlapping addresses and whether SMBUS devices show up regardless. Trackpads could potentially be transplanted from a modern device enabling the best of both HIDs.

Questions:

(does windows use specific laptop power savings? [Done with custom TDP up and downs? Maybe it would actually be fine]).

How flexible is the SMBUS, (does clock speed change or matter) does the bios lock these down?

Concern 6 - Redirect to X60

As this project was quickly growing excessively, I decided to redirect to a smaller version of the project which I had hoped would allow me to avoid the above issues by using a preexisting laptop to gut and transfer. Whilst the orignal idea of this was to try to develop a method to allow for reuse of popular laptop chassis, the complexity has made me reconsider this until I have a better understanding of the laptops interelated systems and software.

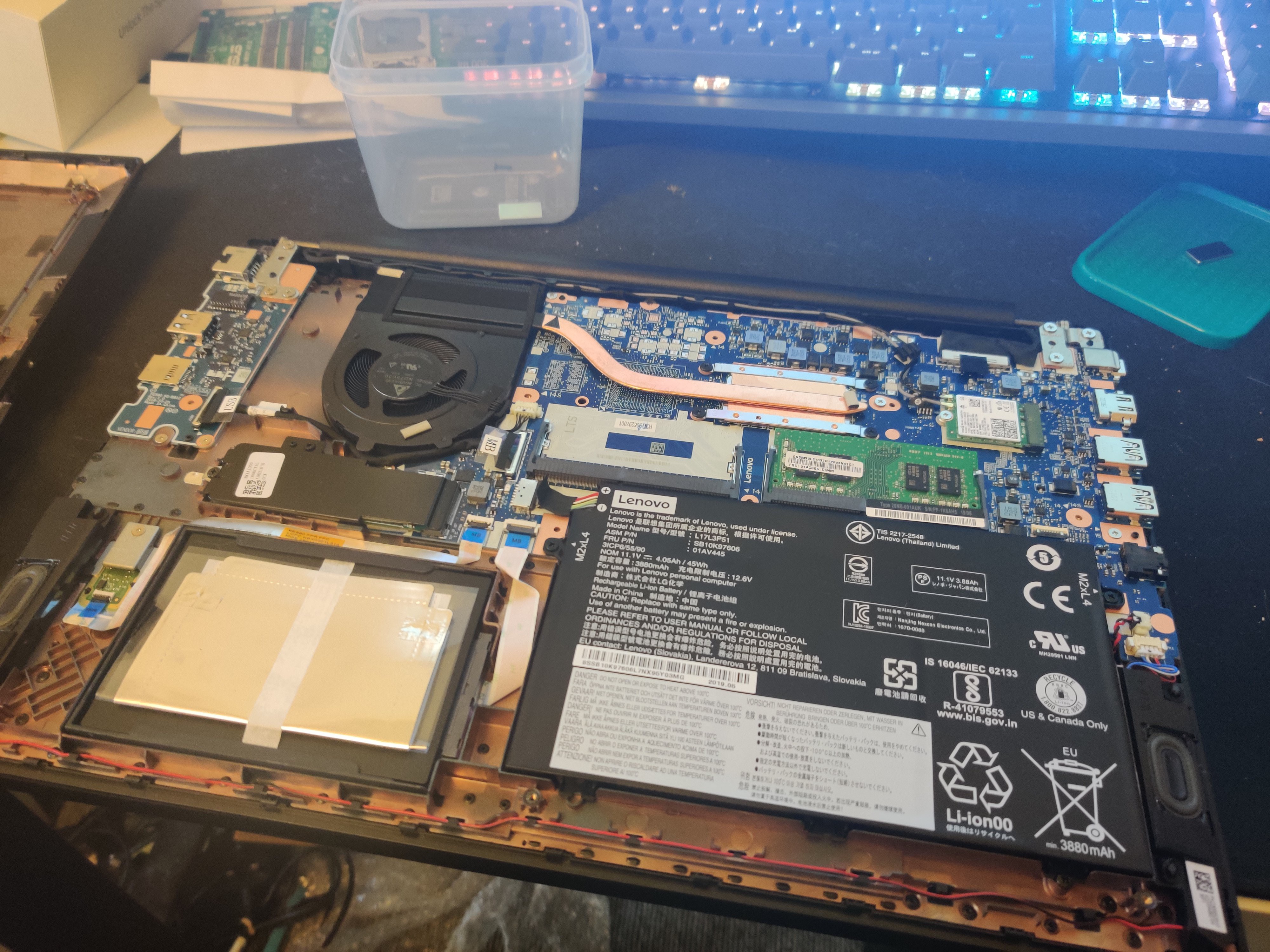

The Thinkpad E590 was chosen to be squeezed inside the x60 chassis

Sean

Sean

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.