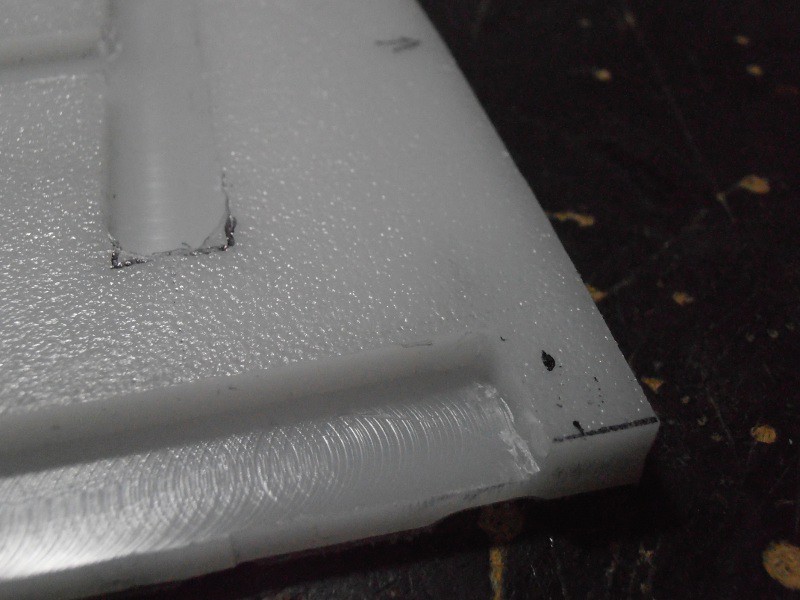

After making my layout I took my cutting board to work, and after hours I milled out the dado's that key the parts together. Now I dont know if I grabbed the wrong bit, or there's a 32nd of an inch of a wobble in the mill spindle (it is a pretty junky and abused machine) but instead of 3/8ths inch wide dado's I anded up with 7/16ths.

Now I know the poor craftsman blames his tools, and I know I am not a master machinest or anything, but jeez, really, 7/16ths? 1/16th of an inch too wide...

Whatever its done and the only dado that really counts is the one holding the cart slot shelf, and its doing its job wonderfully, epoxy will fill in the 32nd of a inch gap on either side of everything else.

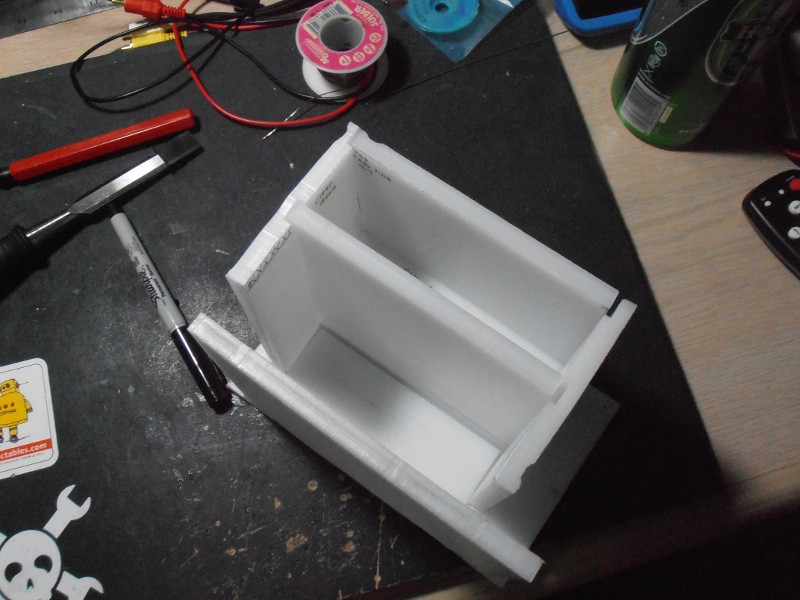

I then band sawed the components out of the sheet, and for free hand they are not too squirmy. Once home I squared off the rounded ends of the dado with a razor sharp chisel, just like in wood it sliced right down easily with hand pressure.

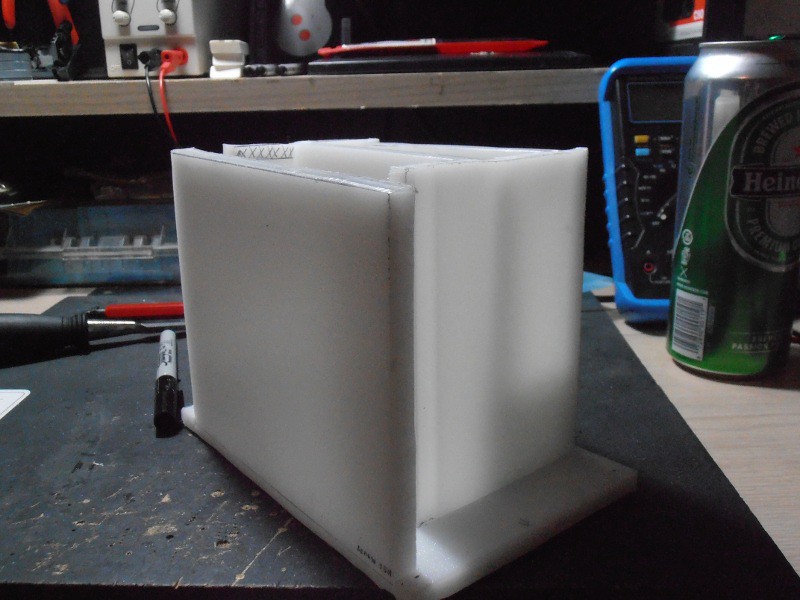

Despite the uneven cuts and the extra wide dado's the parts fit fairly well right now, and are able to stand by themselves with only gravity and friction holding it together (and there aint much friction on poly prop)

Next steps with the plastic is to use a block plane to square up the wobbly cuts then start pre drilling for screws, glue will only be at the very end to fill any gaps, prevent squeaks and moans and finalize the plastic structure.

osgeld

osgeld

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.