I built this for the challenge, I was inspired to improve upon the ideas that (former Mythbuster) Jamie Hyneman shared in his project videos from 2015.

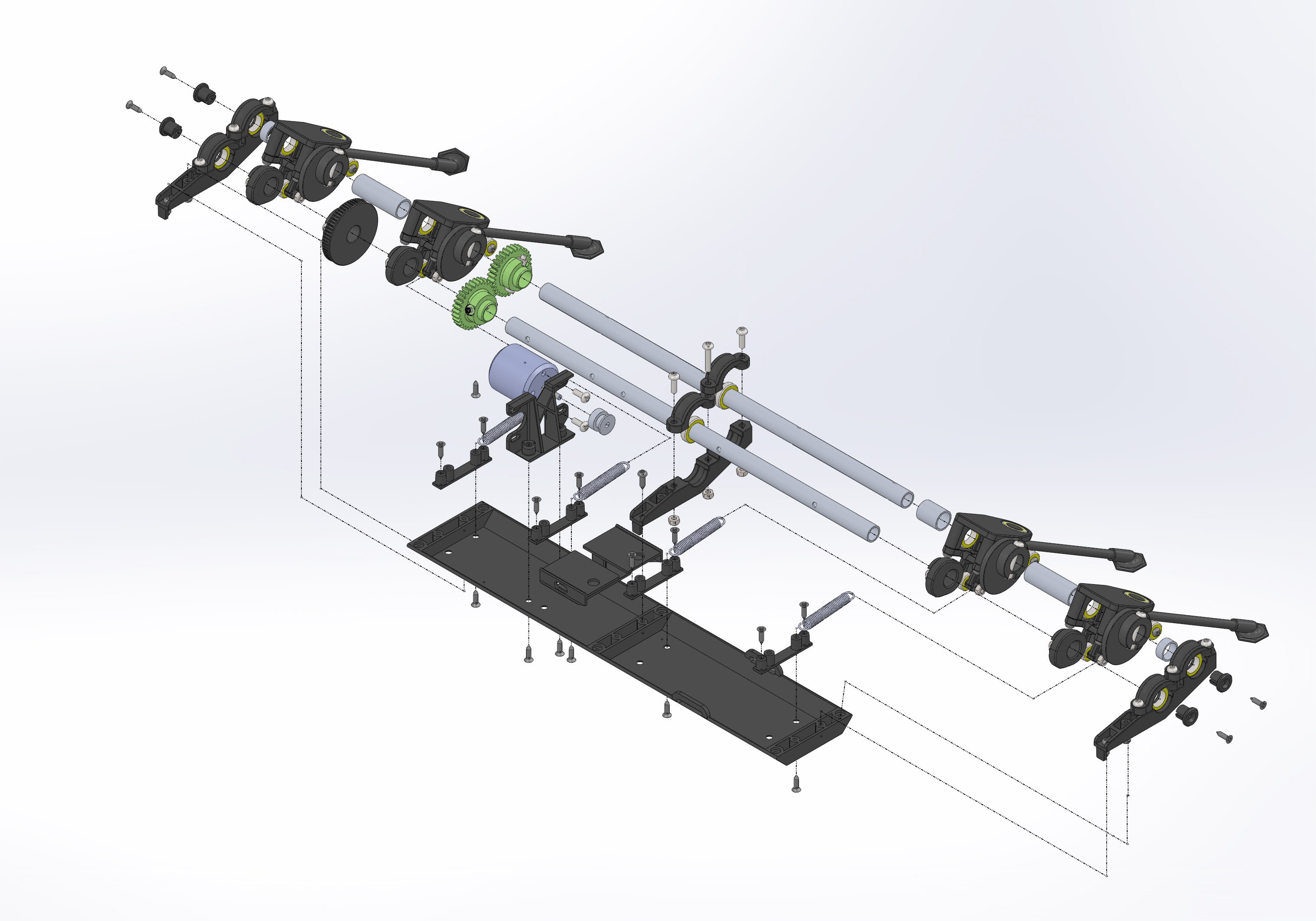

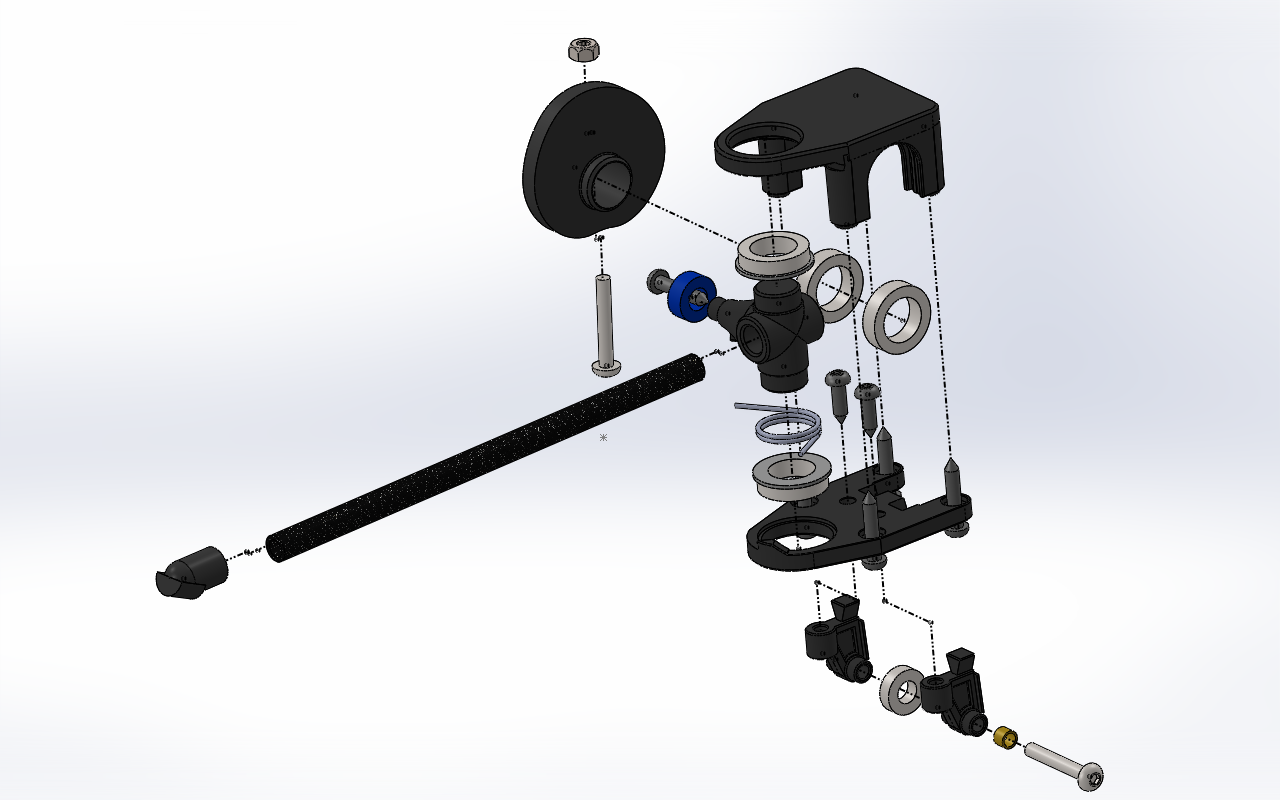

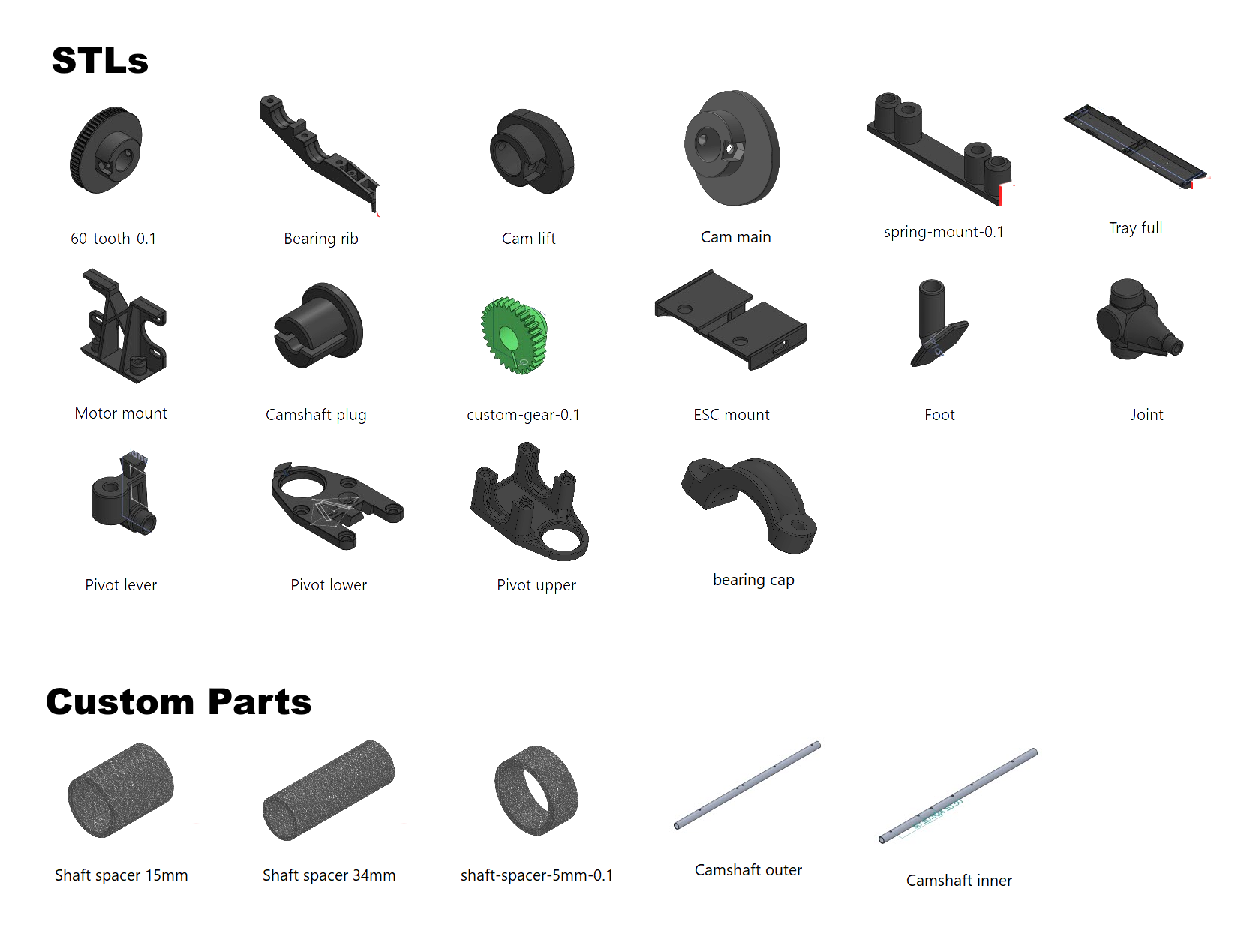

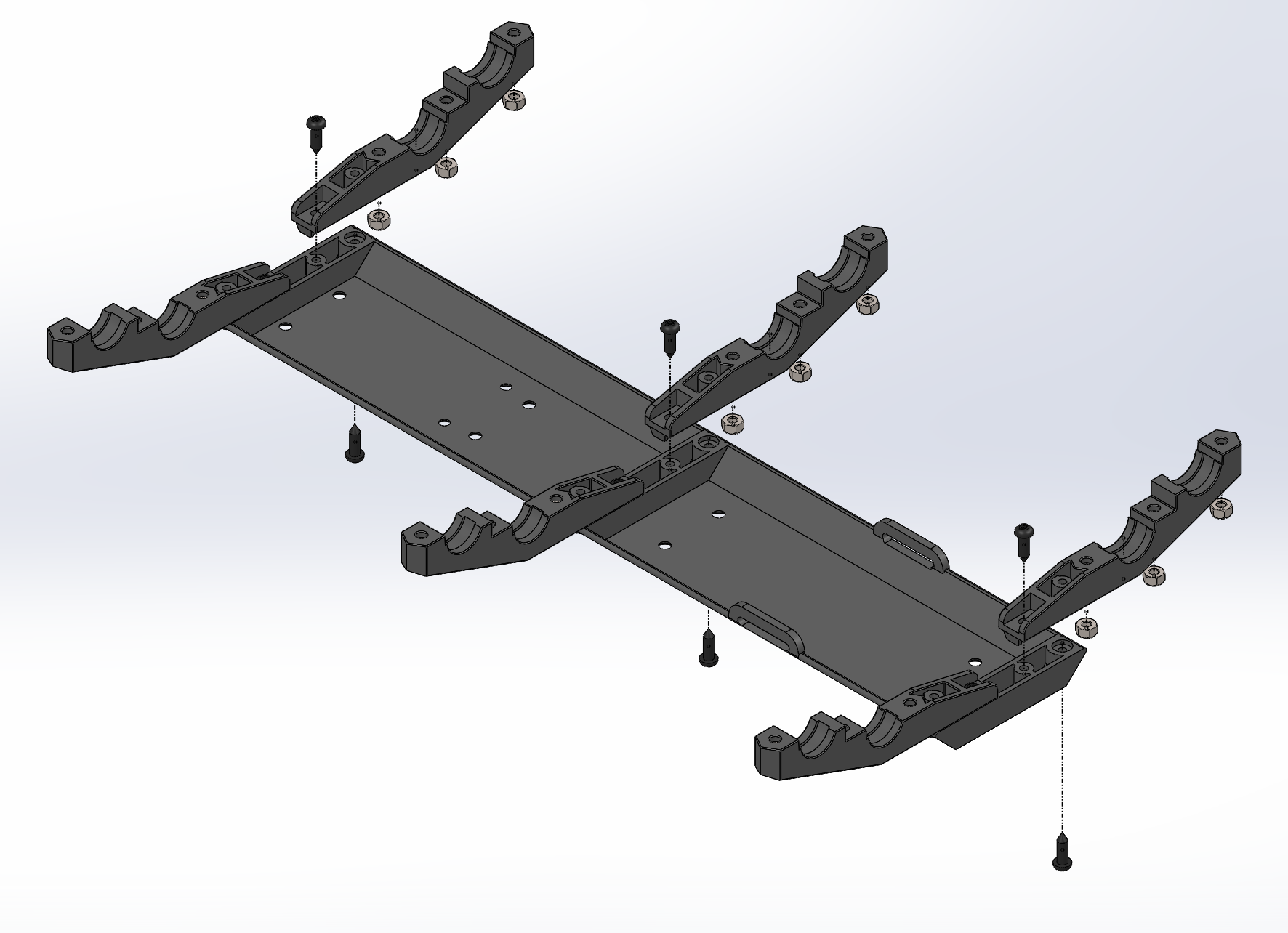

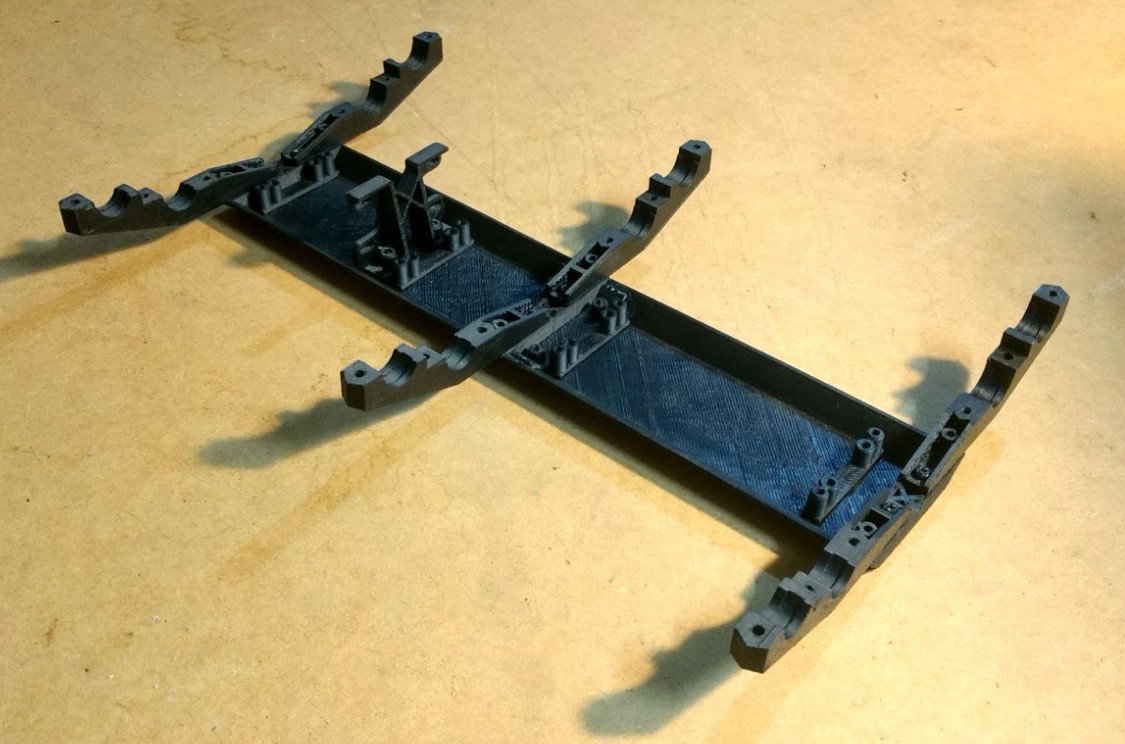

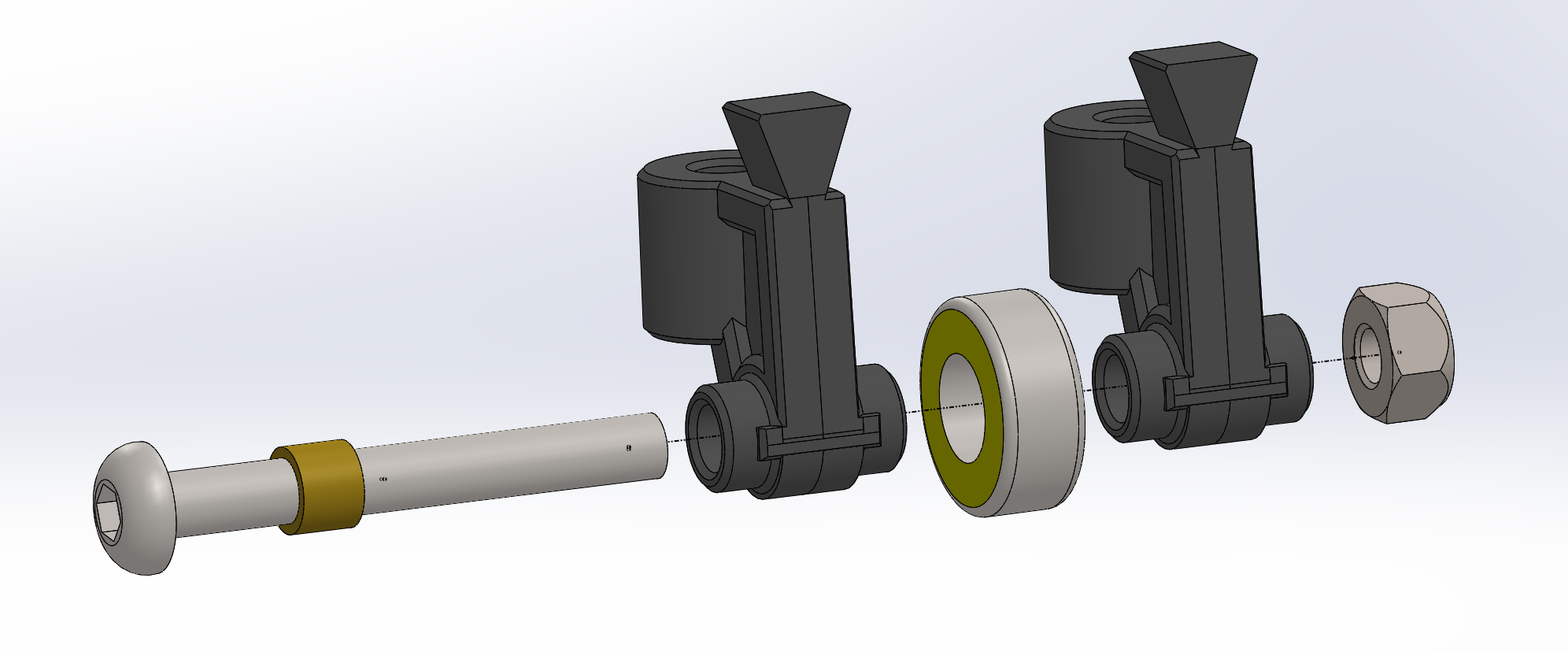

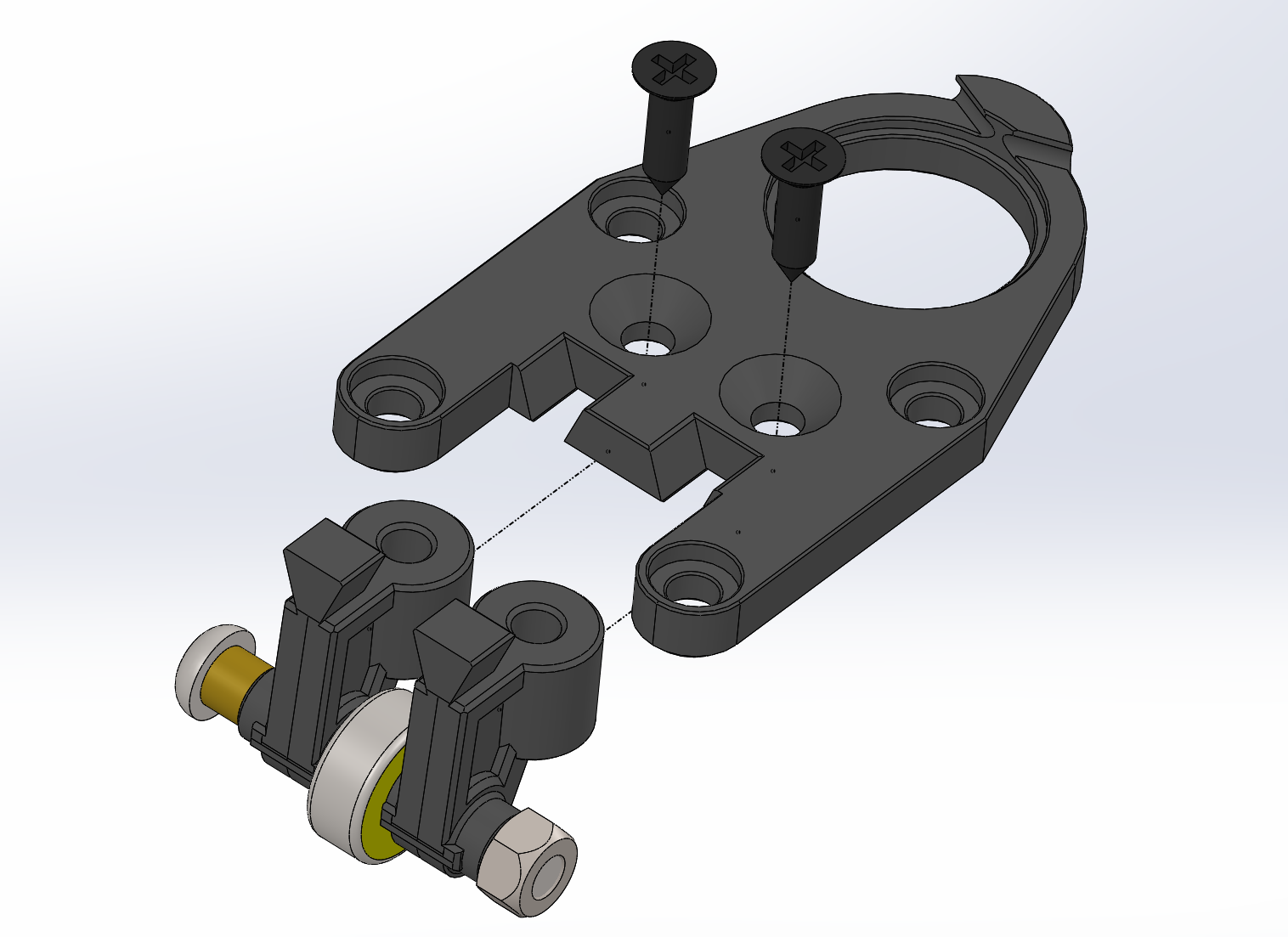

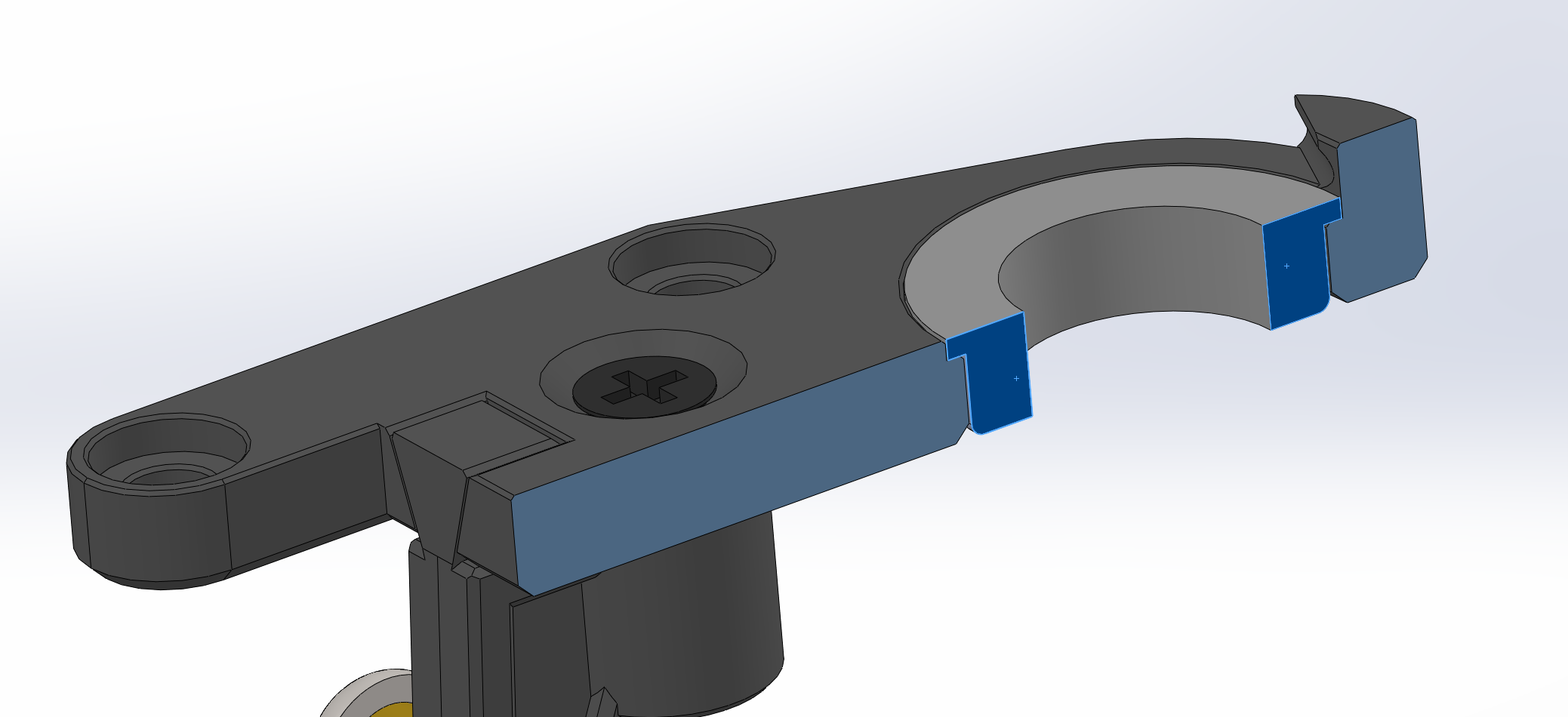

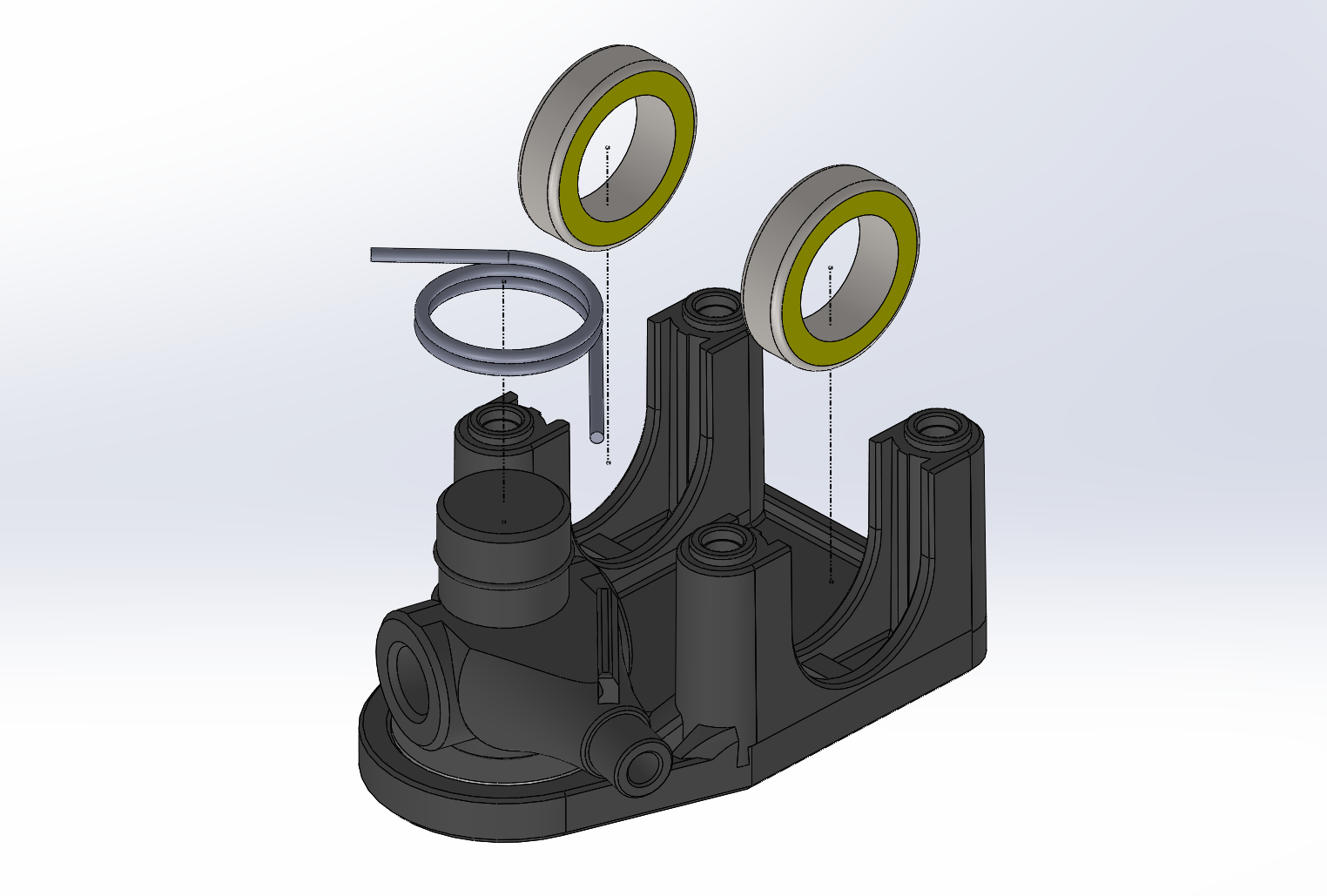

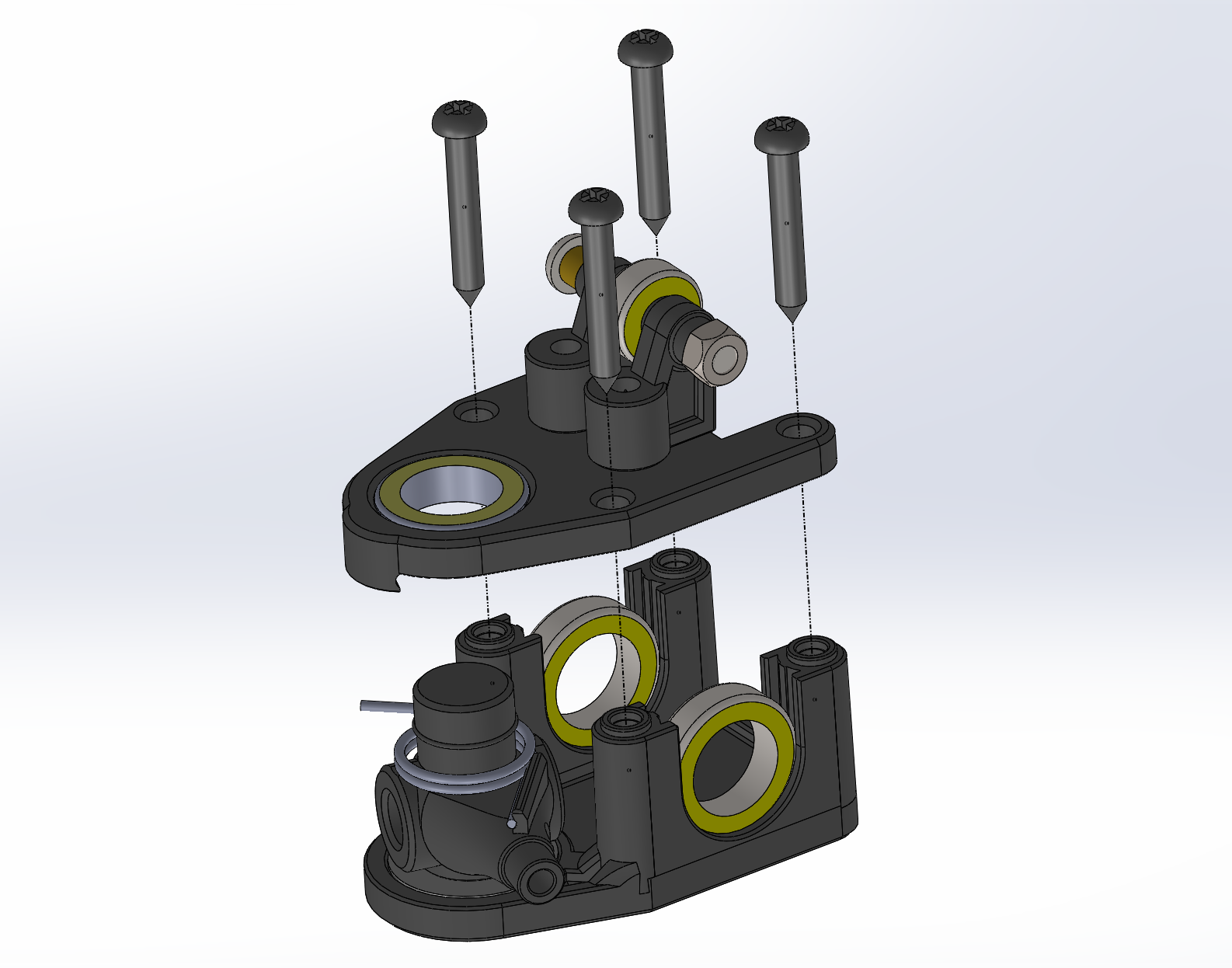

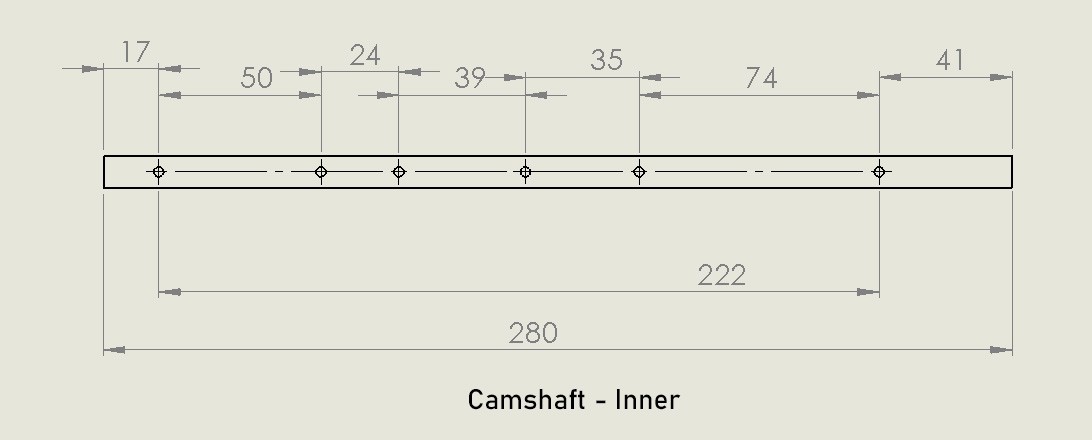

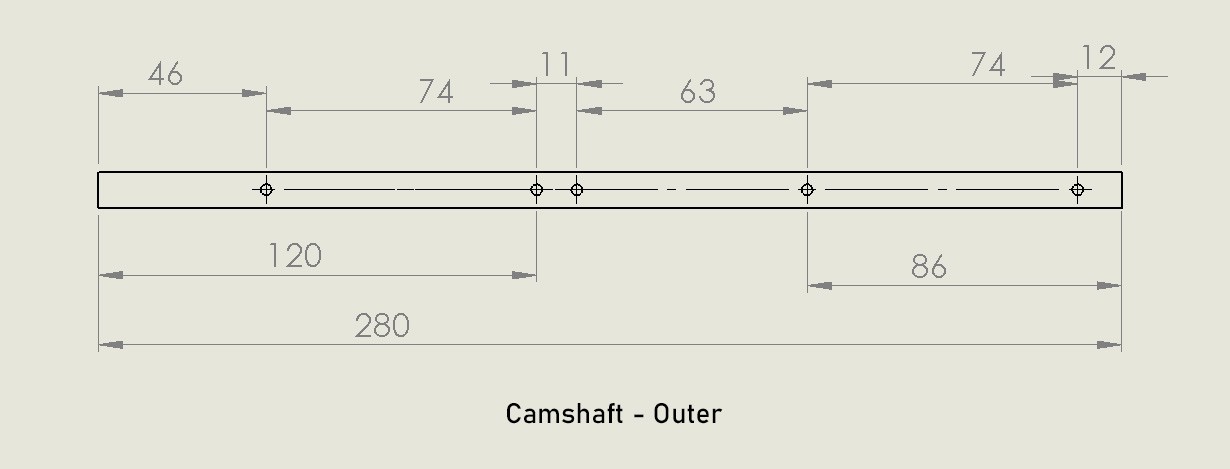

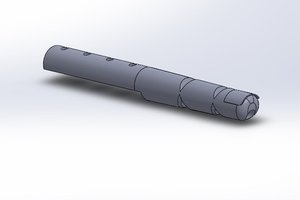

The key my version of his creepy crawly is what I'm calling a Flexapod mechanism. An Arrangement of cams, shafts and bearings that enables super radpid movement and adaptability over rough ground. Also it is quite capable of making people's skin crawl and squirm.

It uses 3D printing and off-the-shelf RC parts: battery, bearings, motors, controllers, screws, bolts aswell as a few custom bits. All of which I will explain as I endeavour to share this project for those who want to build one of their own.

So if you keen to build it, let me know and I will help you where I can.

Russell Munro

Russell Munro

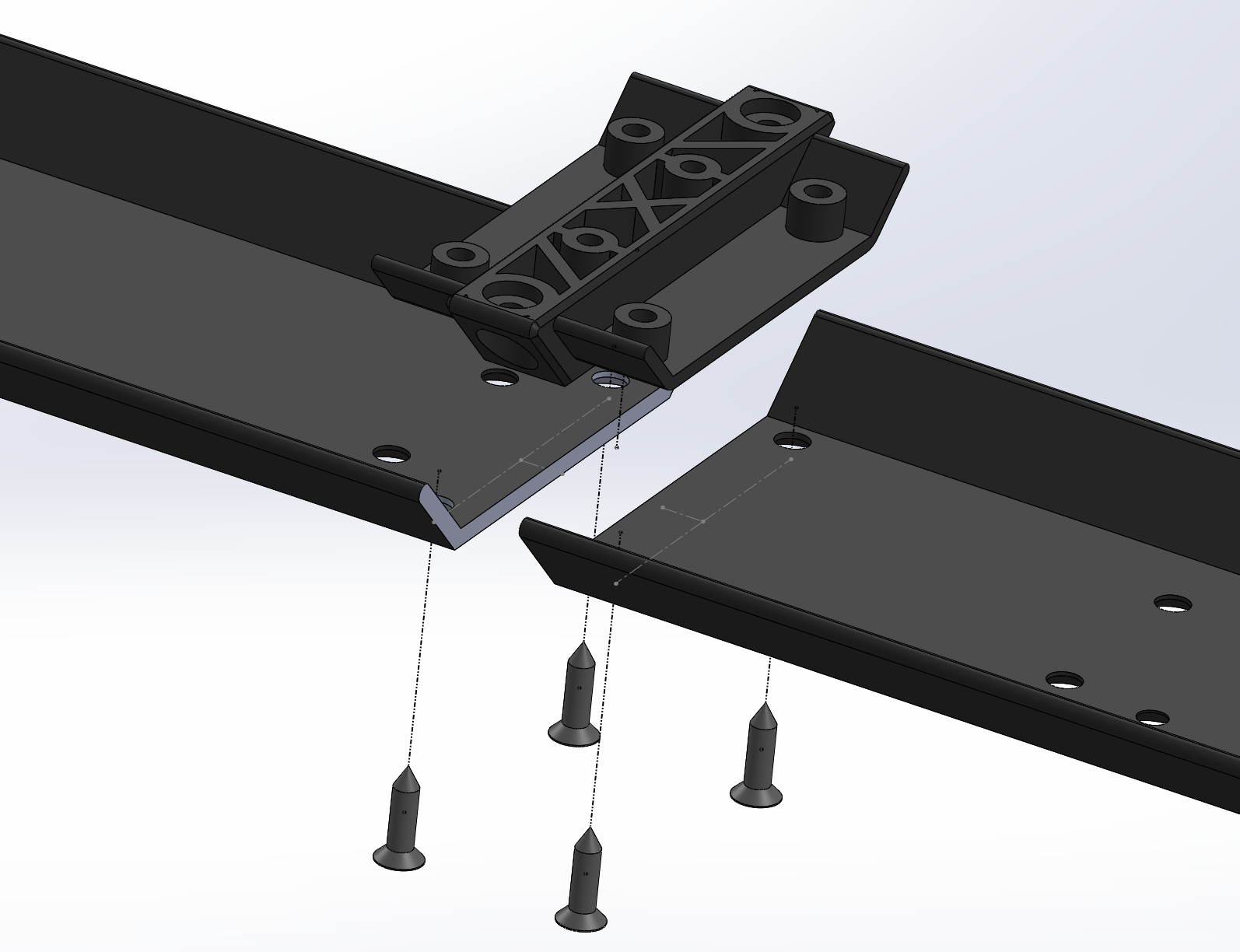

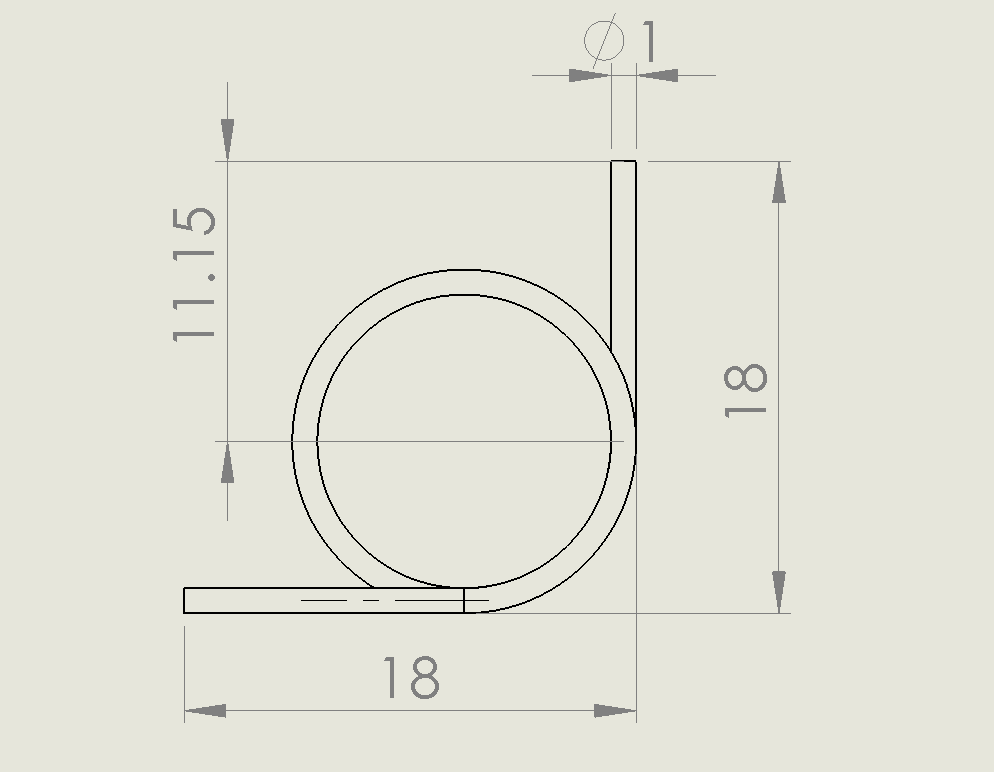

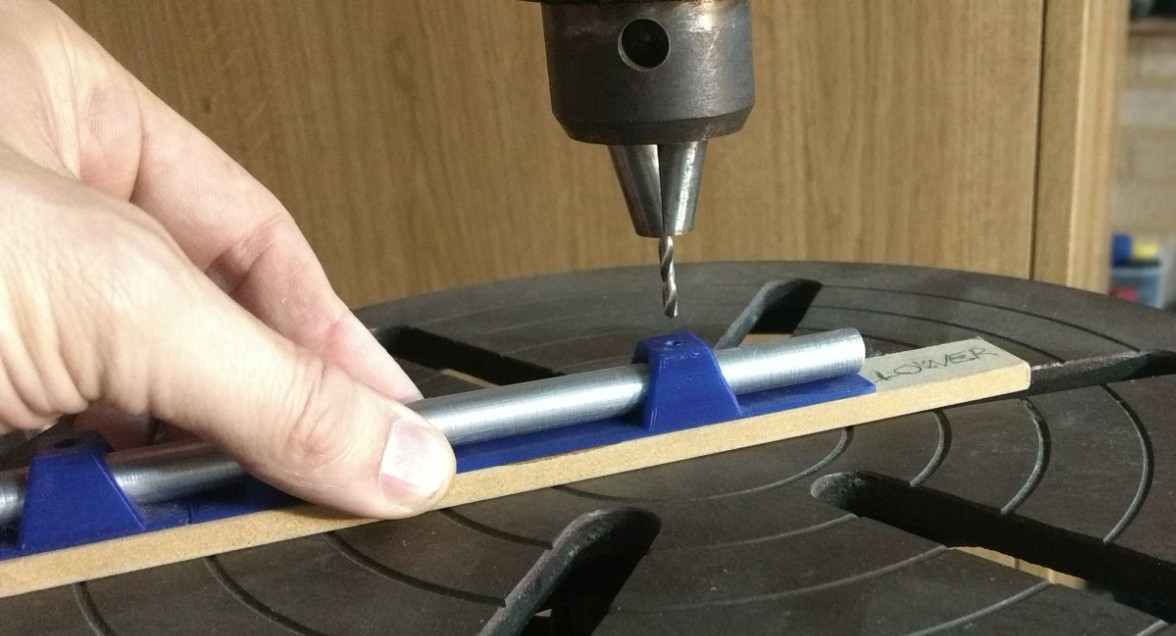

E) Check the alignment by inserting M3 bolts or nails into the holes and look along the length of the shaft. Ideally all the bolts/nails should all be parallel. If not you should check that your drill bit is nice and sharp and consider drilling a new shaft.

E) Check the alignment by inserting M3 bolts or nails into the holes and look along the length of the shaft. Ideally all the bolts/nails should all be parallel. If not you should check that your drill bit is nice and sharp and consider drilling a new shaft.

Xo Ne Un

Xo Ne Un

Aaron P.

Aaron P.

Alan Chambers

Alan Chambers

Brian Brocken

Brian Brocken

This project looks fantastic. It's very seldom that I see something that makes me want to just print and build someone else's work without that obsessive desire to recreate it myself, but the work you've done on the cams etc. is really impressive, and the results speak for themselves!

Bit of a bummer that we're stuck in lockdown for 21 days, time to start pricing the parts at least I guess!