So, as per my last log, the oven is not heating up fast enough partially due to thermal losses. I decided to do the best I can insulating it.

I insulated the inside using a self-adhesive mat that we use at work for engine heat rejection from the exhaust manifold. It is apparently rated for 300C so it should do. We'll see how it holds up. The back of this oven is a single piece of sheet metal so that's probably the worst area for heat loss. There is a piece of insulation on the bottom of the oven as well. I screwed the top pieces into the sheet metal. Even though the insulation may hold up, the glue might not and then it will fall on top of the heater. That clearly can't lead to anything good.

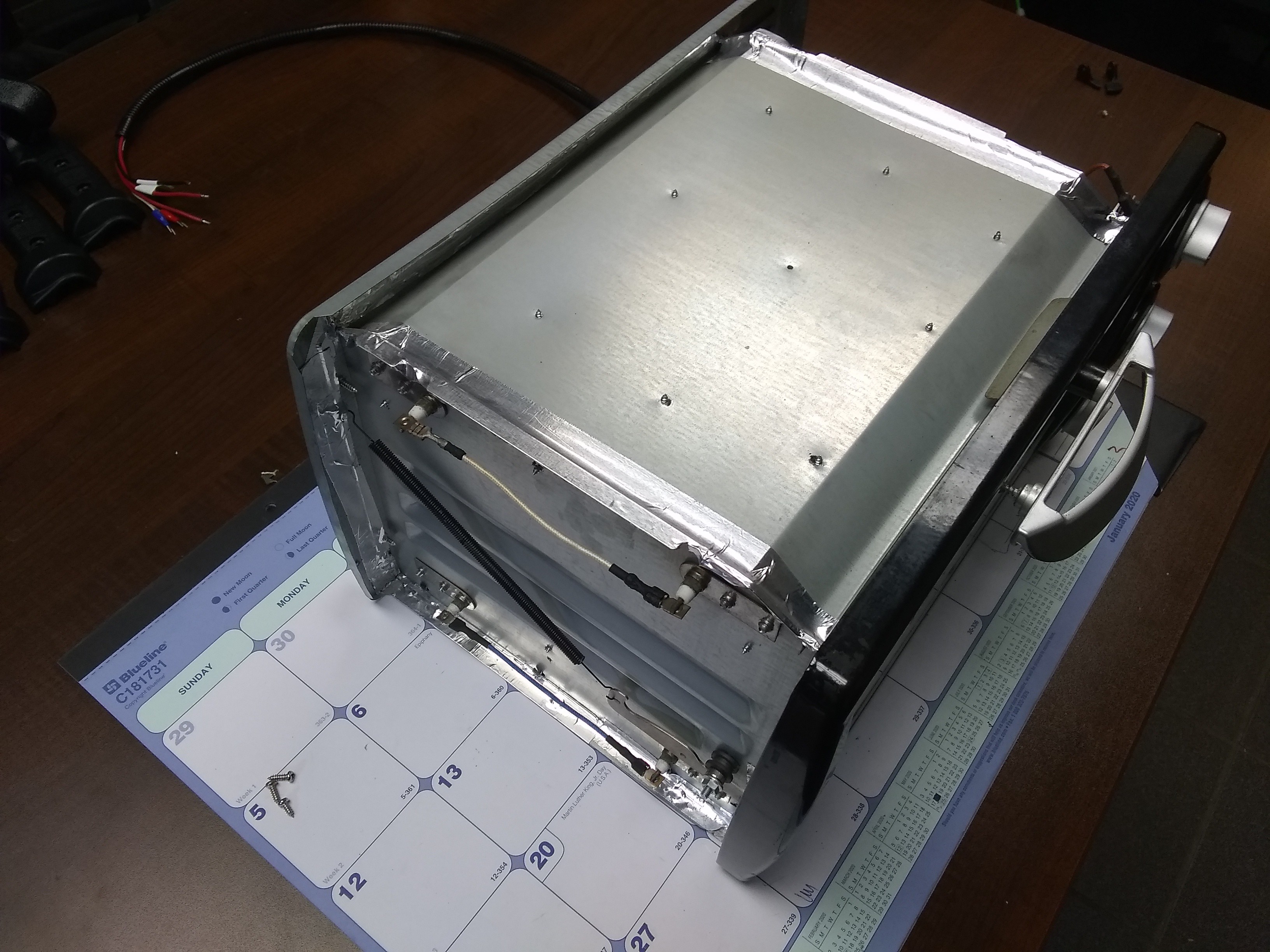

Then I took the cover off and used tin furnace tape to seal all seams between the "heat box" and the body of the oven. This was a rather tedious process but I can only hope that it will improve things as a whole.

Finally, before putting the cover back on, I noticed that there is a fair amount of air gap between the heating box and the cover. I suppose this was just more room where insulation could be added. Had to stick the insulation to the cover so that the shiny side was pointing towards the "heat box". No screwing down was necessary since once it is pressed together (the insulation was a bit thicker than the air gap) it will have nowhere to go.

Once it was bolted back together, it looked pretty good. I didn't like the fact that I can't see inside it now since I added insulation to the glass door. I supposes one can't help this.

TheGrim

TheGrim

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.