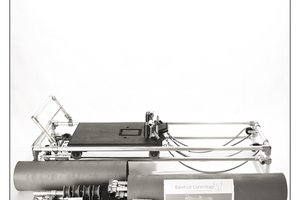

The project was designed to use widely available materials effectively. It uses one sheet of plywood and one tarp. I am placing the design into public domain. Please modify and improve! Desired improvements include: better wheels (current configuration makes a lot of noise), base feet, tent attachment mechanism, tent entrance, better tarp material. Please msg me if you improve the design.

Here is a video:

https://cdn.hackaday.io/files/1702727284917248/camper2020-03-27.avi

Matherials:

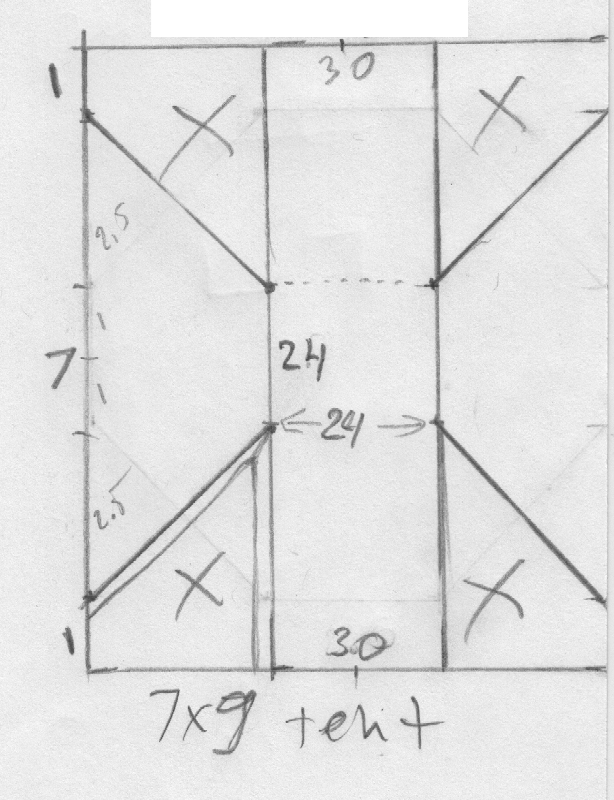

- 1 7'x9' blue tarp ( $5 @ harbor freight)

- 4 Coasters 3" ( $8 12x18 dolly @ harbor freight)

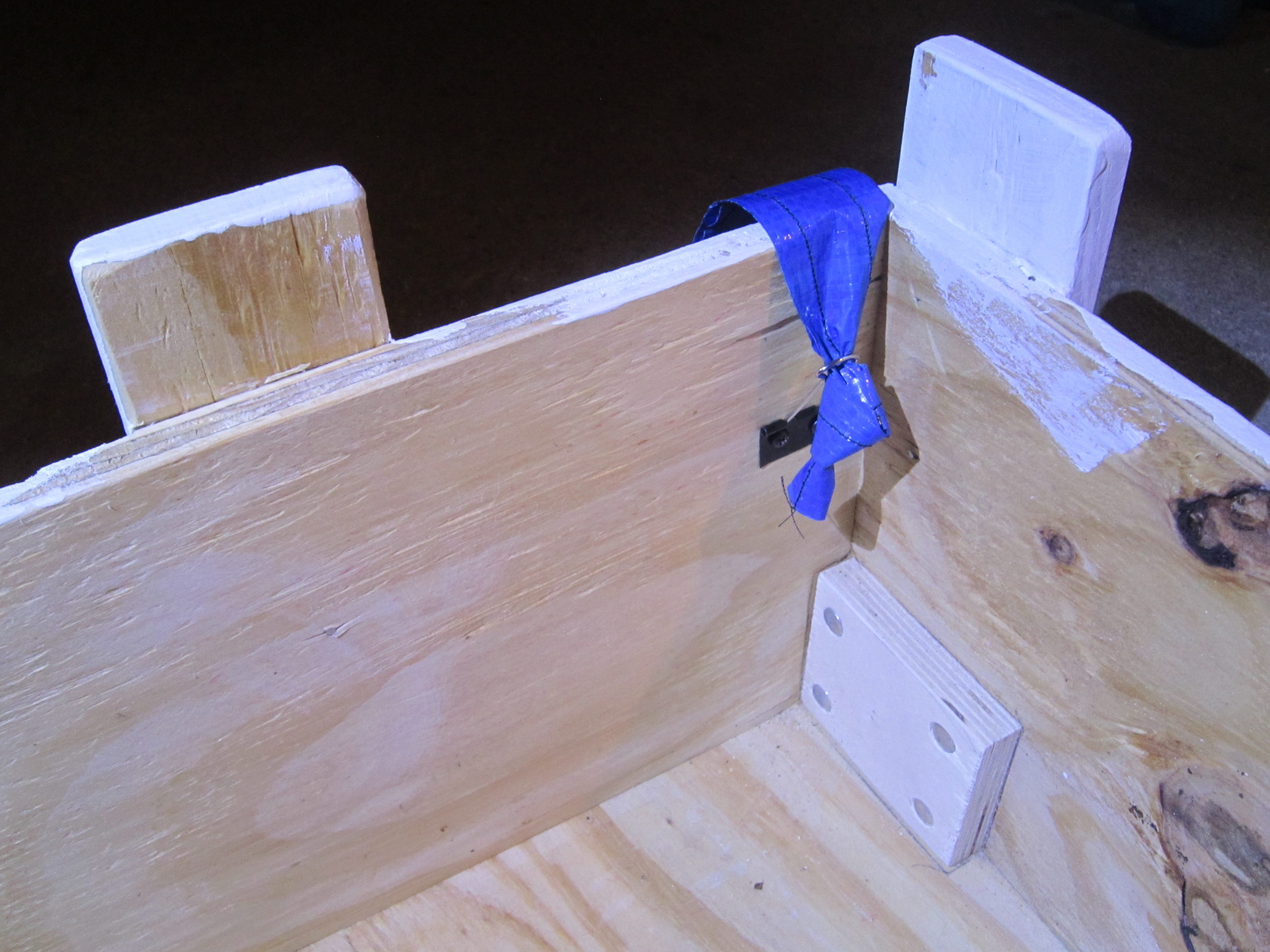

- 4 Hinges ( $2 each @ harbor freight)

- 1 Hasp & Staple 3" ($2.29 @ harbor freight)

- 1 lock ( ~$3 @ harbor freight)

- 2 1/2" sch 40 pvc pipe 10ft ( $1.98 @ homedepot)

- 8 1/2" 90 degree pvc elbows ( $0.36 @ homedepot)

- 4 1/2" pvc caps ( $0.49 @ homedepot)

- 1 PVC cement ($8 @ homedepot)

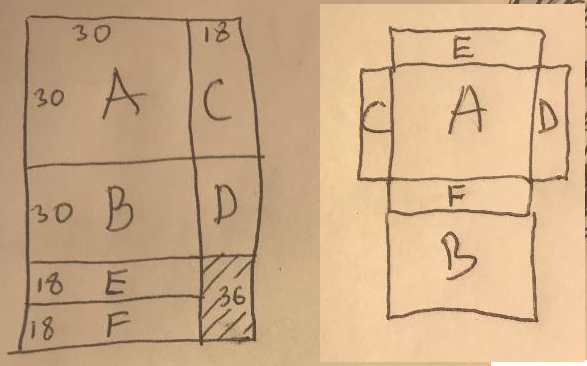

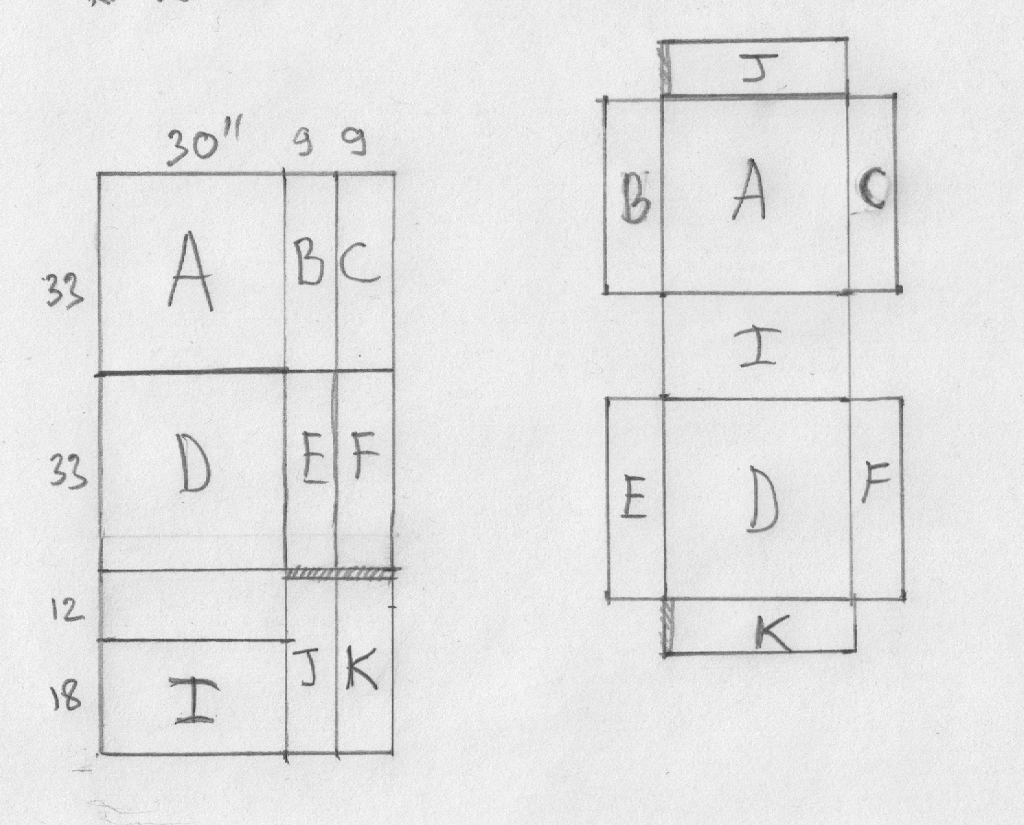

- 1 Sheet of 19/32 or 5/8 plywood ($20 @ homedepot)

- Wood Glue ( $3 @ homedepot)

- 50 coarse thread 1" screws ( $6 @ homedepot)

- 50 #8 coarse thread 2.5" screws ( $6 @ homedepot)

- 1 quart exterior paint ( oops paint @ homedepot)

- thick plastic for making feet ( I used a kitchen cutting board )

- thread for sawing the tarp ($3 @ Michael's craft store)

- 4 medium sized paper clips for attaching the tent straps to base

Tools:

- measuring tape

- gloves for working with plywood

- saw for cutting plywood and pvc pipe

- drill

- drill bits to pre-drill screw holes, coaster bolts and paper clips

- 7/8" drill/spade bit for 1/2" pvc pipe holes

- hex screw driver

- pencil for marking wood

- paper towel for wiping excess glue

- wrench for disassembling the dolly and attaching the coasters

- tin snips for cutting paper clips

- 3" paint brush

- rasp or alike for rounding sharp corners

- permanent marker for marking the tarp

- scissors for cutting the tarp

- sawing machine for sawing the tarp

rand3289

rand3289

joseph

joseph

Joel Fairstein

Joel Fairstein

Simply7

Simply7

barb

barb

Thanks! Please feel free to use the project materials in any way you would like. They are all in public domain. I hope someone other than me makes a few of these and gives them to homeless people. Also, I want to make you aware of this project: https://www.edar.org/ which has very similar goals. They are a non-profit organization. Their "carts" are a bit expensive though costing around $500 since they are manufactured commercially