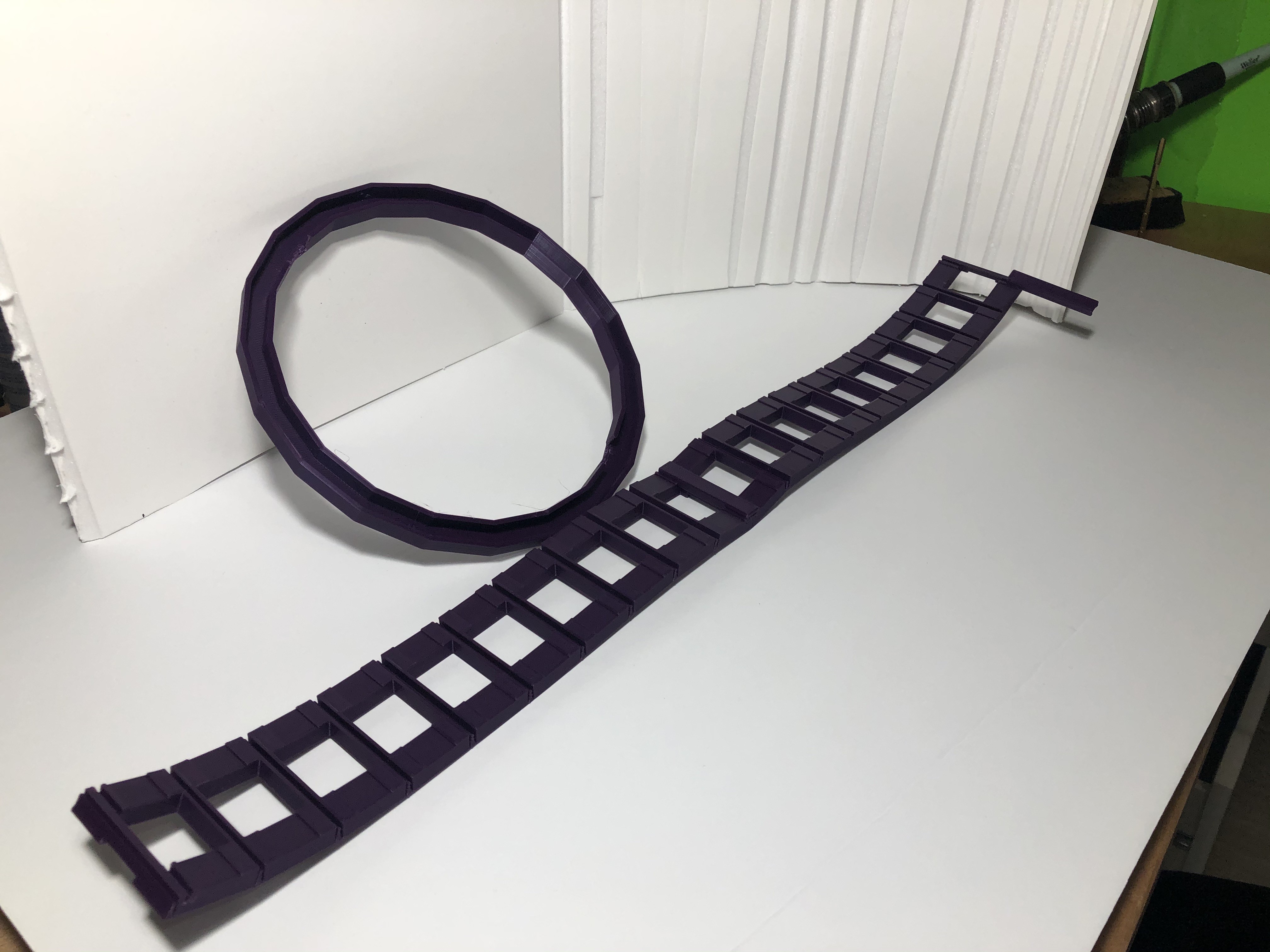

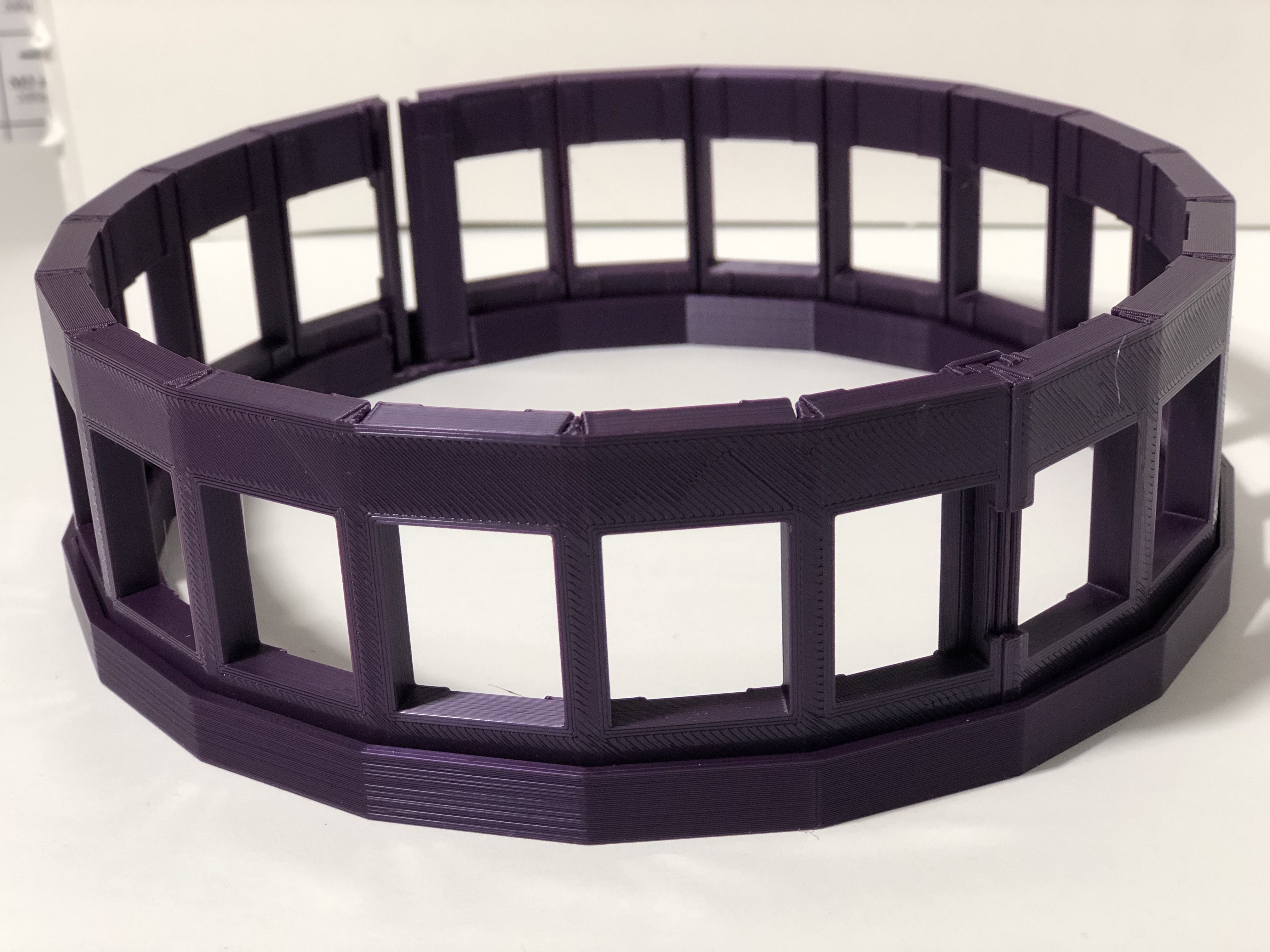

I printed another trial for the LED ring. The outer ring prints flat in two strips. These strips are then folded int a rough right and the sections connect using dovetail clips.

Also, there is a topper ring to hold the whole thing in a roughly cylindrical shape. I need to adjust the size of the ring so that the strips fit perfectly.

I ordered some 60 LED/meter strips (5 meters long). For 60 LEDs/meter, the LED repetition pitch is 16.54 mm. That will give 300 LEDs to make into an array. I'm currently thinking about an 8x32 array to make a satisfying 8-bit amount (256 LEDs).

Also, I will add 2-3 columns that are blacked out to hide the wires that interconnect the rows of LED strips. That will make effectively 35 colums. I am considering running the LED strips the long way (32 LEDs per strip) so that I will only have to wire up 8 ends. That will give a ring approximately 222mm in diameter (about 9 inches). More mechanical design is required to verify.

Things to figure out:

1. When rolling up the strip into a ring, need to keep the final size of 16.54mm pitch on the inside of the ring.

2. How to keep the LED strips in place?

- Hot glue (bleh!)

- Springy clips: How to keep them in place without coming off

- Clips that are then welded on with the soldering iron. I like this idea, but repairability will be low. Maybe that's a positive feature.

kmatch98

kmatch98

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.