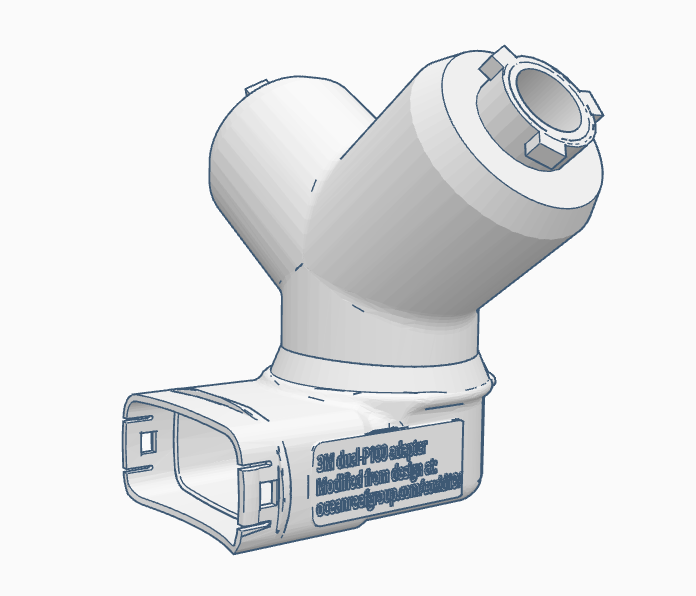

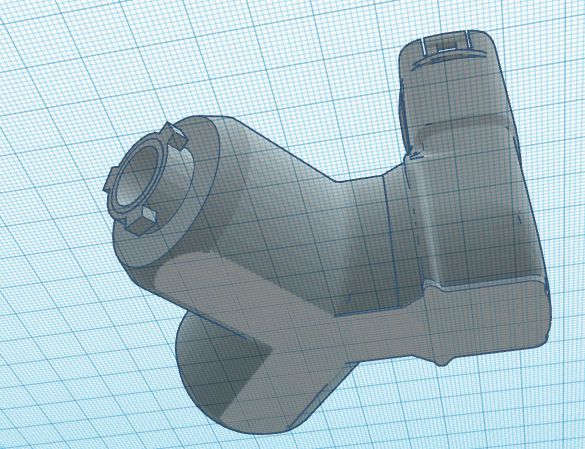

We next made a dual filter design to increase air-flow and enable easier use of the mask. We chose a 3M P100 particulate filter with 99.97 % filter efficiency meeting NIOSH P100-series test criteria. While this is an excellent filter, it has become hard to find so we will look into adapting our design for other filters.

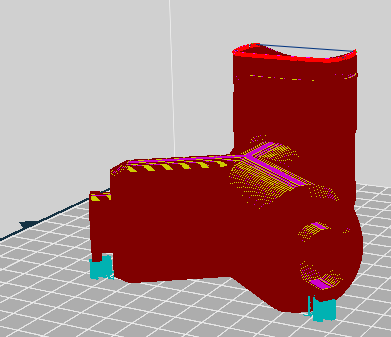

Breathing through this adapter with both 3M P100 filters installed was much better than our single filter model so we moved forward with quantitative testing. For quantitative testing we printed the adapter in black PLA. NOTE: PLA prints are porous and without an airtight coating they will not work for this application! We coated the print in 2 coats of XTC-3D (Smooth-On, Inc., Pennsylvania, USA) to make it airtight. One 3M 3PRG7 (3M, St. Paul, MN) inhalation port gasket was placed at each of the two inhalation ports. Finally, one P100 filter was attached at each of the two inhalation ports. Sticky putty (Alcolin, Cape Town, South Africa) was also used to ensure an airtight seal between the mask and the snorkel connector. Ideally, we would use a different process to create this adapter in a material that can form a perfect seal without the putty. However, given the ubiquitousness of FDM 3D printers and ease of printing in PLA, we thought it useful to present results from our testing in this material, with putty to achieve the air-tight seal. Here is a photo of the coated test adapter installed on a mask with putty:

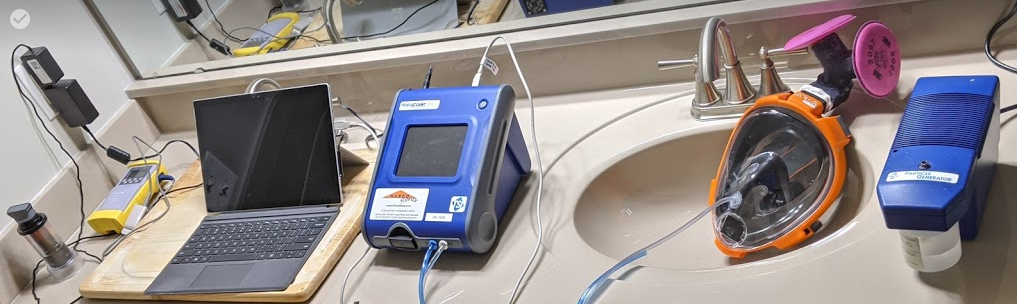

Fit testing was performed using the OSHA 29CFR1910. 134 protocol in the PortaCount 8030. Here is the equipment used in the test:

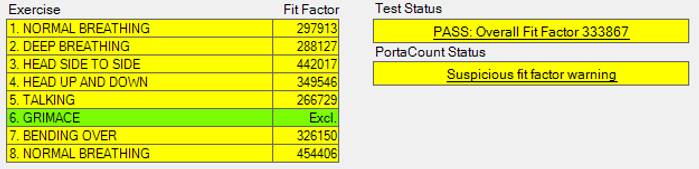

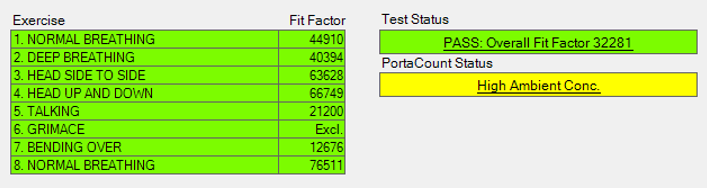

The fit test exercises include normal breathing, deep breathing, turning the head side to side, moving the head up and down, talking, grimace, bending over, and normal breathing. Each test exercise lasts one minute except for the grimace exercise which is 15 seconds. A passing fit factor for full face masks like this design is 500, while for half face masks is 100.

The 6800 series 3M mask served as our benchmark and reached its maximum fit factor in 1:15 minutes. O2 Saturation remained stable. Real time test results can be seen here:

https://drive.google.com/file/d/1hY2ZT3B8HeySWEC7M7wPVEo2ACfaUtaZ/view?usp=sharing

The 3M mask passed the fit test results with a fit factor of 333867. Fogging or humidity were not an issue.

In our test condition we removed the exhalation mushroom valve and plastic cover from the mask and covered the resulting hole with duct tape. This makes the mask less comfortable but removes the possibility of an infected mask user inadvertently exhaling viral particles.

This configuration reached its maximum fit factor in approximately 2:11 minutes. O2 Saturation remained stable. Real time test results can be seen here:

https://drive.google.com/file/d/1ETWlNk0VjiZnSMaRXsm5R3HmVk0Zrd-M/view?usp=sharing

This configuration passed the fit test results with a fit factor of 32281. Increased humidity decreased the comfort of the mask although fogging was minor.

Subjective user experience

A radiation therapist wore the mask from 9 AM to 3 PM while performing daily work activities which require an increased level of exertion while positioning and moving patients to the treatment couch of the linear accelerator. She took off the mask for lunch and for a break to have a drink. Visibility was great and comfort better than other PPE she had used. Near the end of the daily with increased physical activity she felt some breathing discomfort. She measured the O2 sat at the time which was 100 %. Overall her feedback was that it was a comfortable option she could tolerate for prolonged periods of time.

Conclusion:

The modified full-faced snorkel mask tested solved two critical PPE problems in the current COVID-19 crisis: eye and face protection, and high quality air filtration to protect against SARS-CoV-2. The solution exceeded the OSHA requirements for a full faced mask in quantitative testing, and can be another alternative in the current climate of PPE shortage. We release the adapter design as open-source so users are able to modify this design to fit filters from different manufacturers (as we did from the Ocean Reef design), depending on the current supply.

Lex Kravitz

Lex Kravitz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.