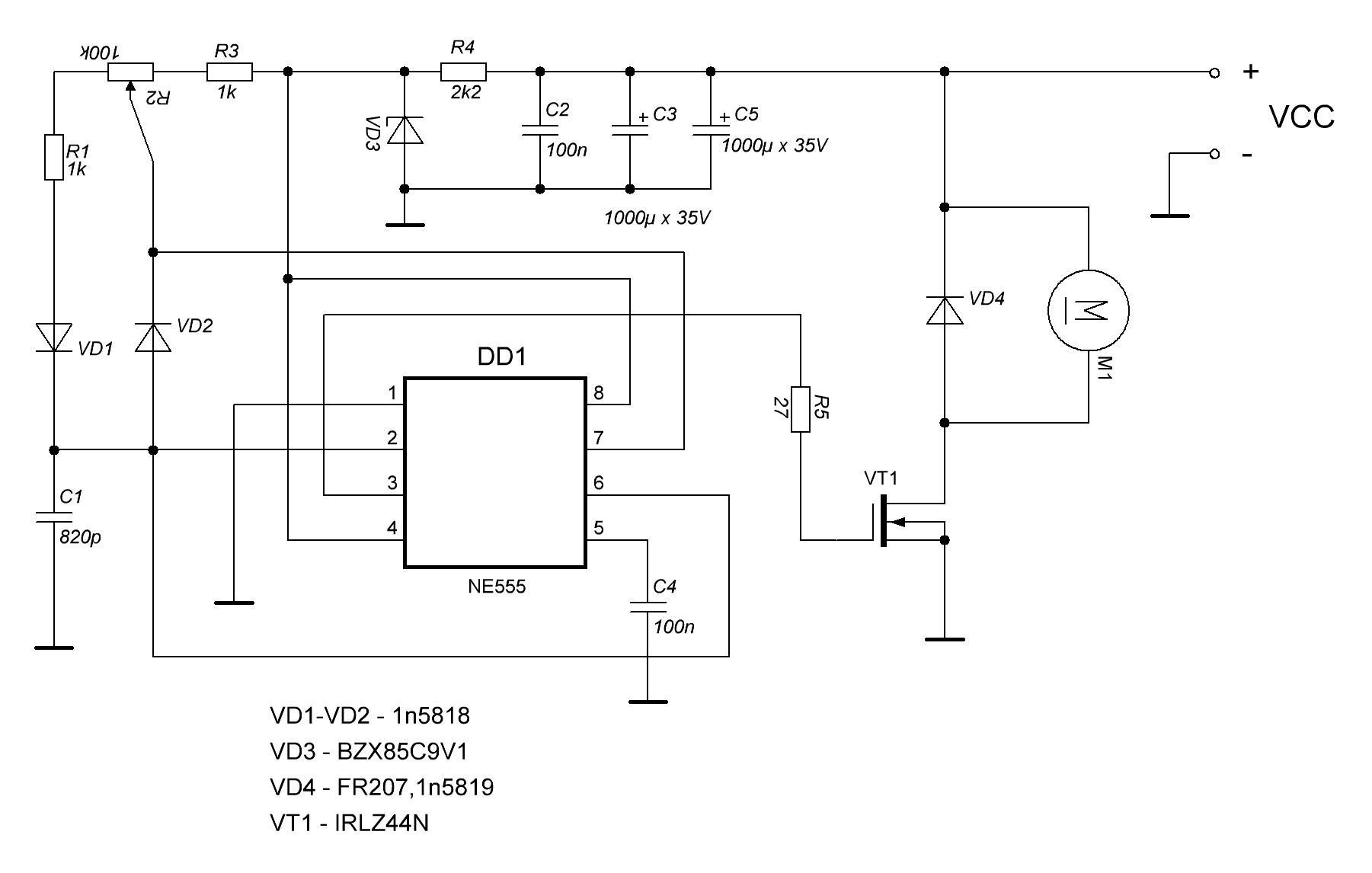

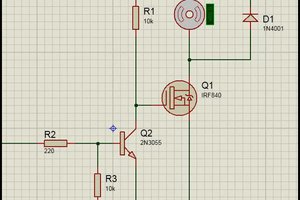

The device on the NE555 IC made it possible to implement a pulse-width modulated power regulator, which is used in conjunction with DC-powered devices. It has high efficiency, high load capacity and a wide range of supply voltages. It can be used to control the speed of rotation of DC collector motors, the power of DC heating devices, incandescent lamps, with a maximum current depending on the power source and the output transistor key.

The device is assembled on an integral timer, it works in pulse generator mode with a constant frequency and a powerful MOSFET transistor. The duty cycle and pulse length is changed by the position of the potentiometer, this allows you to adjust the duty factor of the PWM, and therefore the average power in the load.

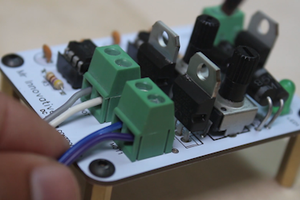

The power supply voltage of the device must not exceed 27V DC. A MOSFET transistor operating in a switch mode is used as a regulatory element. Since in the open state, the drain-source transition resistance has a very low resistance, a small amount of heat is generated on the transistor, even when switching currents 10A. But just in case, I installed a 50cm2 heat sink.

ATTENTION: Do not connect heat sink to ground!

And what about DC motor? I disassembled the old Soviet mother’s hair dryer (mom thanks for the hair dryer =)) from 80's, removed the electric motor from there, bought a set of brass collet clamps on the radio market and tried to drill.

ATTENTION: Do not connect MOSFET drain pin to ground!

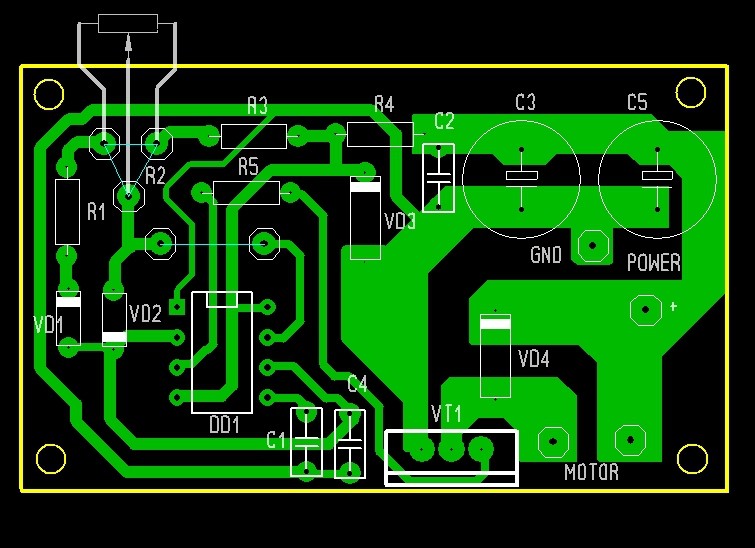

The circuit was drawn in sPlan 7 and PCB in sLayout

Circuit diagram:

PCB:

Work video:

Osman Mazinov

Osman Mazinov

Electroniclovers123

Electroniclovers123

Mrinnovative

Mrinnovative

UTSOURCE

UTSOURCE