The time has come to discuss how to go from prototype to the production version.

Plastic/Resin Parts:

At the moment all the prototype parts have been 3d printed in both ABS plastic and resin. For the production version there are a few ways we could go:

- Keep the parts 3D printed

- This lets us make small changes without manufacturing an new mould.

- Lets users print spare parts if broken.

- Parts injection moulded

- An element of redesign would have to be done to make the 3D printed parts injection friendly

- This will certainly decrease part cost of Qty of 1000.

- Hybrid design

- Have all Major parts injection moulded that won't be changed in the future.

- Have all other parts 3D printed, on a industrial scale.

While we mature this design to the production level we will have a better idea of which method to take.

Mechanical Parts:

All machinal parts apart from the custom scroll wheel and core unit base are available off the shelf. When we change version we will look at decreasing the brass insert and screw count and use other techniques. This should make the unit cheaper and easier to manufacture

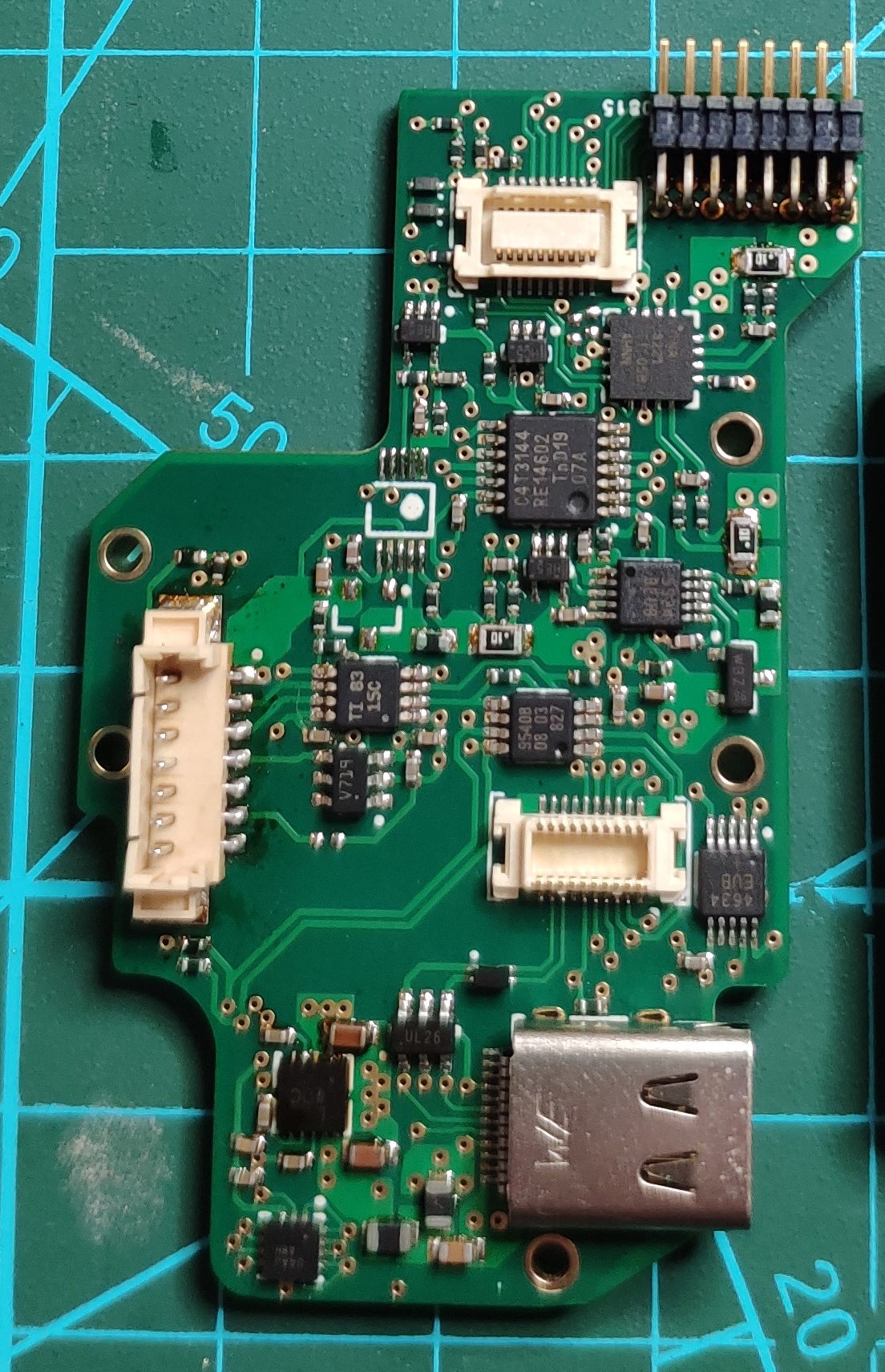

PCBs:

At the moment all module PCB's have been optimised for manufacture and can be manufactured in batches for about £10 each which certainly isn't bad for 4 layers 0.8mm thick double side SMD boards. There is only one board that requires redesign to production level and that is the Dev Interface board.

Now currently this board is a 6 layers 1.6mm thick double side SMD boards and is designed to be a development board that features lots of debug and monitoring circuits. Because of this and the fact it's 6 layers this is probably the most expensive board of the project at around £70 for a batch of 5. After the prototyping stage we will be designed a low cost production version that still has the same level of protection. The key will be to made it 4 layers which instantly reduces the price and allows this PWA to be made in standard pools.

benw

benw

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.