We have been using the first Ender 5 we built for a while now and I got to the lab to finally able to tweak some things that needed doing.. I've decided I will better document the procedures when I build the second printer up.

1.) The firmware I built from the TH3D site did not have stealthchop enabled on the Extruder stepper motor, so it was noisy. I have enabled stealthchop for the extruder stepper motor via the advanced configuration menu inside of marlin menu on the printer itselt, and it's all good now.

2.) The squeaking of the Z axis drive was solved by removing the Z axis leadscrew, cleaning the grease off of it and the brass leadscrew nut with isopropyl alcohol, flipping the leadscrew upside down from the as installed position, and lubricating it with Zoom Spout oil.

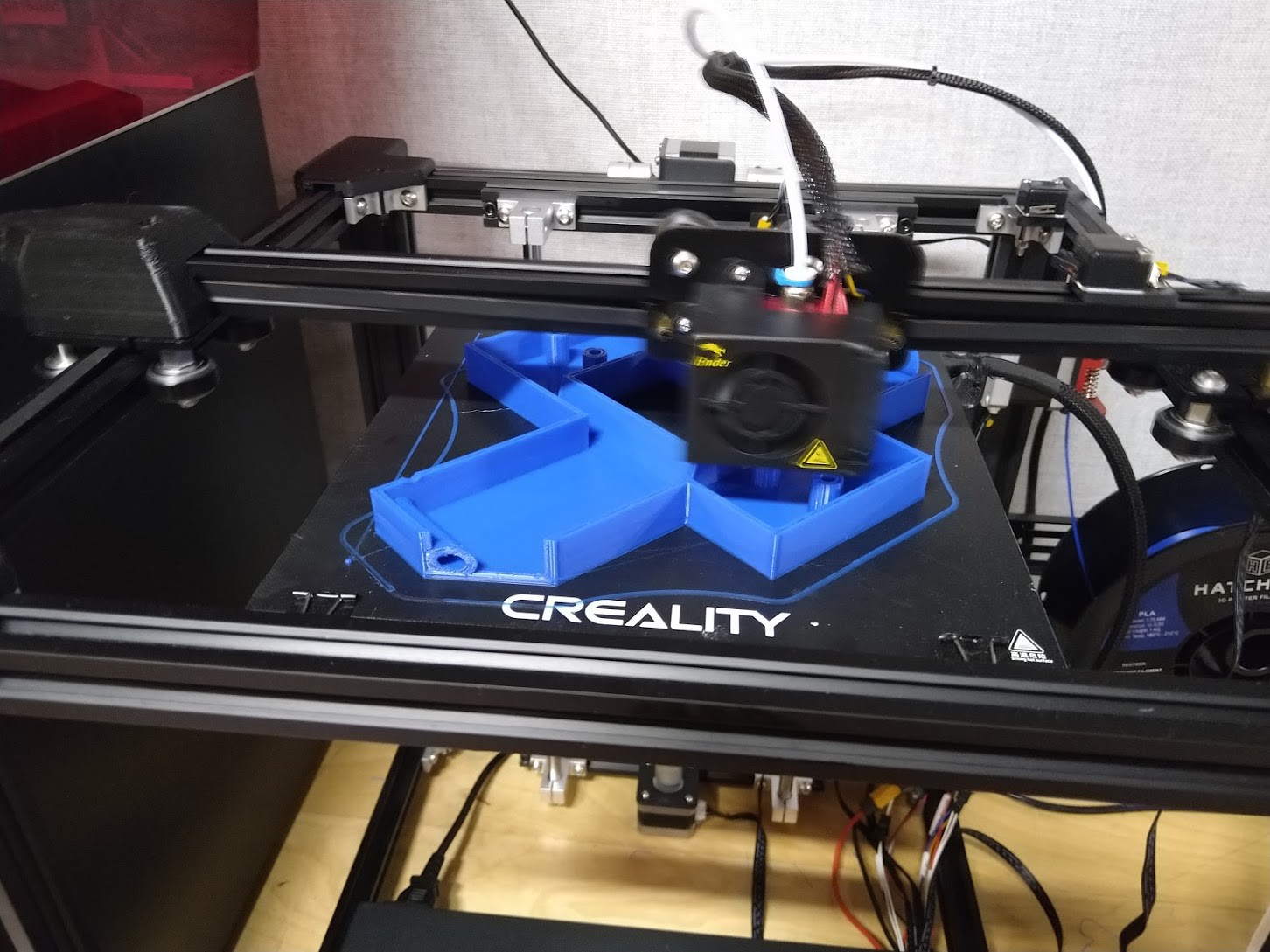

I am happy with the results we've been getting so far. Although I was intending to shim the bed, it may not be needed afterall. The printer is being put through it's paces, and the second printer that was missing finally got delivered. We are still waiting on the BLTouch kits. They have now been shipped, however they have arrived in the states.

I have decided I will build the second printer with the BLTouch kit and also document the steps I missed when building the first machine. I'm set on finding any issues with the bed leveler, and also learning how to use it, before I modify the first printer.

Other than that, both machines will likely get wiring dress with some clear spiral wrap similar to how I have my own Ender 5 at home set up. I'm not yet sure how I want to try and make the wiring easy to get to if it comes time to replace the hotend or either of the fans, however I want this to be an easy task when the time comes. Just as my own ender 5 at home, the v-groove delrin/plastic bearings do collect dust, and I am trying to decide if a little felt/brush wipe might be in order, or just to have one near the machine for people to manually clean/dust the bearings. I'm thinking we should also get a pack or two of them since they are cheap enough to have laying around as spare parts just in case. Each machine uses 11 of the things. (They can be source on Amazon for around $1 each in packs of pretty much whatever you want, buyer beware though, read the reviews, some are correctly sized, some are not!)

cprossu

cprossu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.