About three months ago, the Hackaday Prize 2020 Conservation X Labs dream team developed a clever 3d printed waterproof mechanical release for an underwater electronics enclosure. The mechanism releases the electronics enclosure from a heavier base once an event occurs. The enclosure then rises to the surface but remains tethered to the base by a rope. Once at the water's surface, a signal can be transmitted.

Their concept was exactly what the BoatDetect solution needed. A way remain underwater during the data collection period so the device can not be tampered with, but then rise to the surface at the end of the data collection period so it is easy to access the data card and replace the batteries. From then on it was a case of "Engineer see good idea; engineer copy good idea and try to make it better."

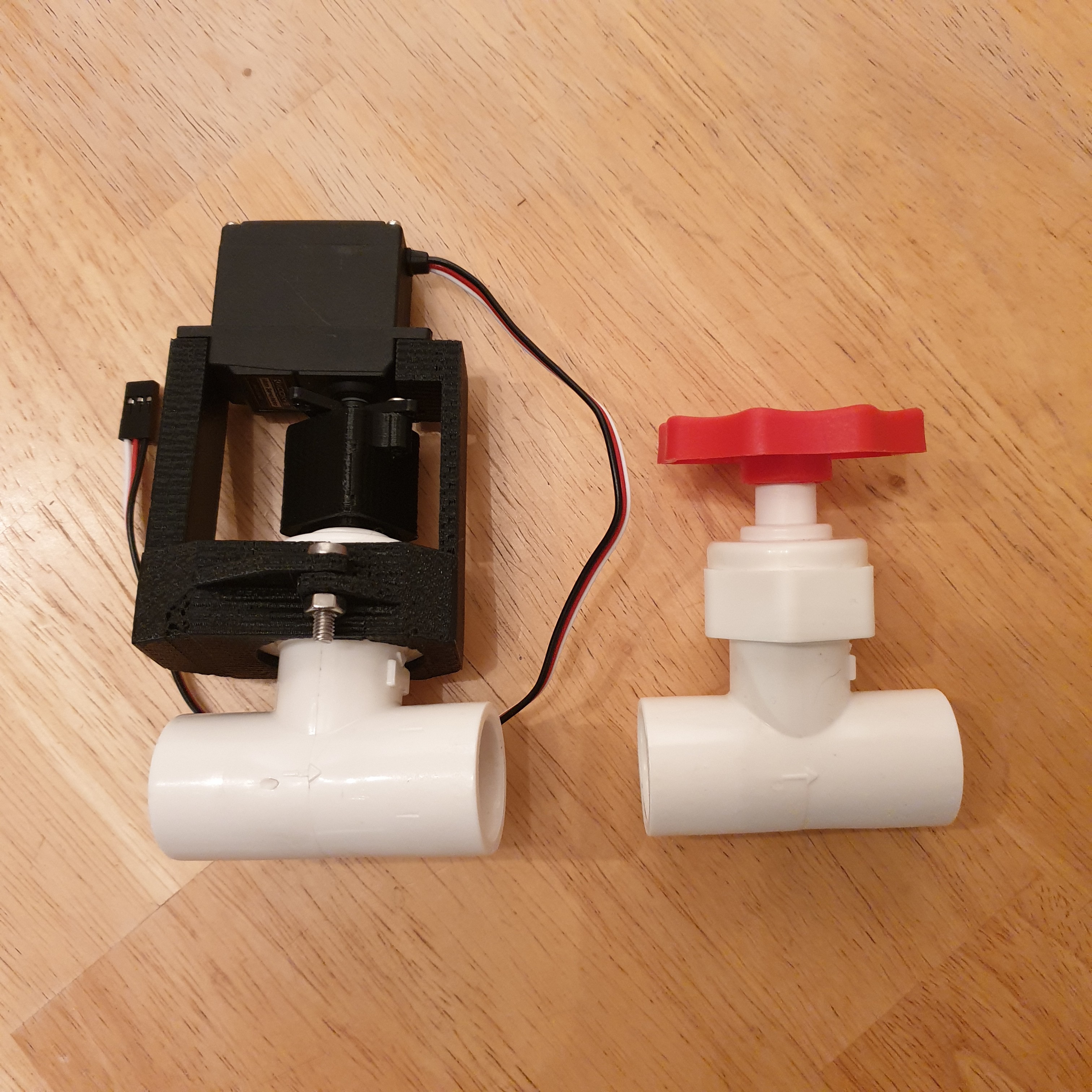

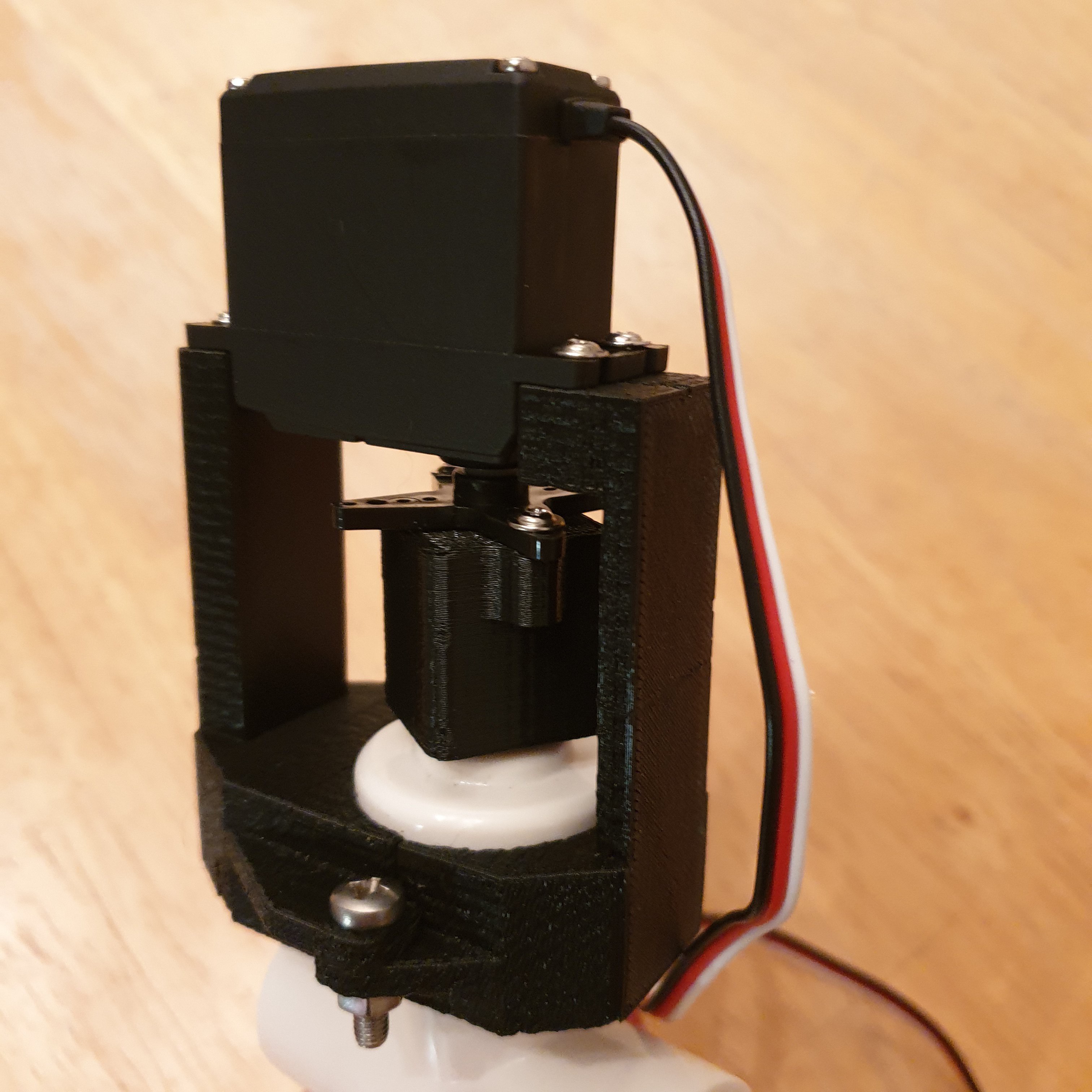

Largely, I believe I am on track to achieve a simpler, more reliable, potentially cheaper pressure-rated waterproof mechanical release for hobbyist underwater electronics enclosures. This design uses a standard PVC stop valve, a continuous rotation servo, four 3d printed parts, and eight small fasteners. When the servo rotates the PVC stop valve on one side, a linear plunger advances on the inside of the valve. To remain submerged, the stop valve plunger captures the end of a pole or rope that is anchored to the seabed. Once the servo is actuated, the stop valve plunger retracts, releases from the pole or rope, and the enclosure floats the to the surface.

It was not until I understood the problem in it's simplest form as "actuate mechanical motion on one side of a waterproof seal and cause mechanical motion on the other side of the seal," that I identified off-the-shelf PVC valves as a great already proven solution. Then it was a matter of finding the right combination of PVC valve and actuation method. PVC ball valves are cheap but cheap 5V servos and stepper motors do not have enough torque to turn them. Stop valves are the second cheapest option but require more rotational travel than a 180 degree servo and more torque than a cheap 5V stepper motor. So a continuous rotation servo is currently the cheapest actuation method I could come up with for the PVC stop valve.

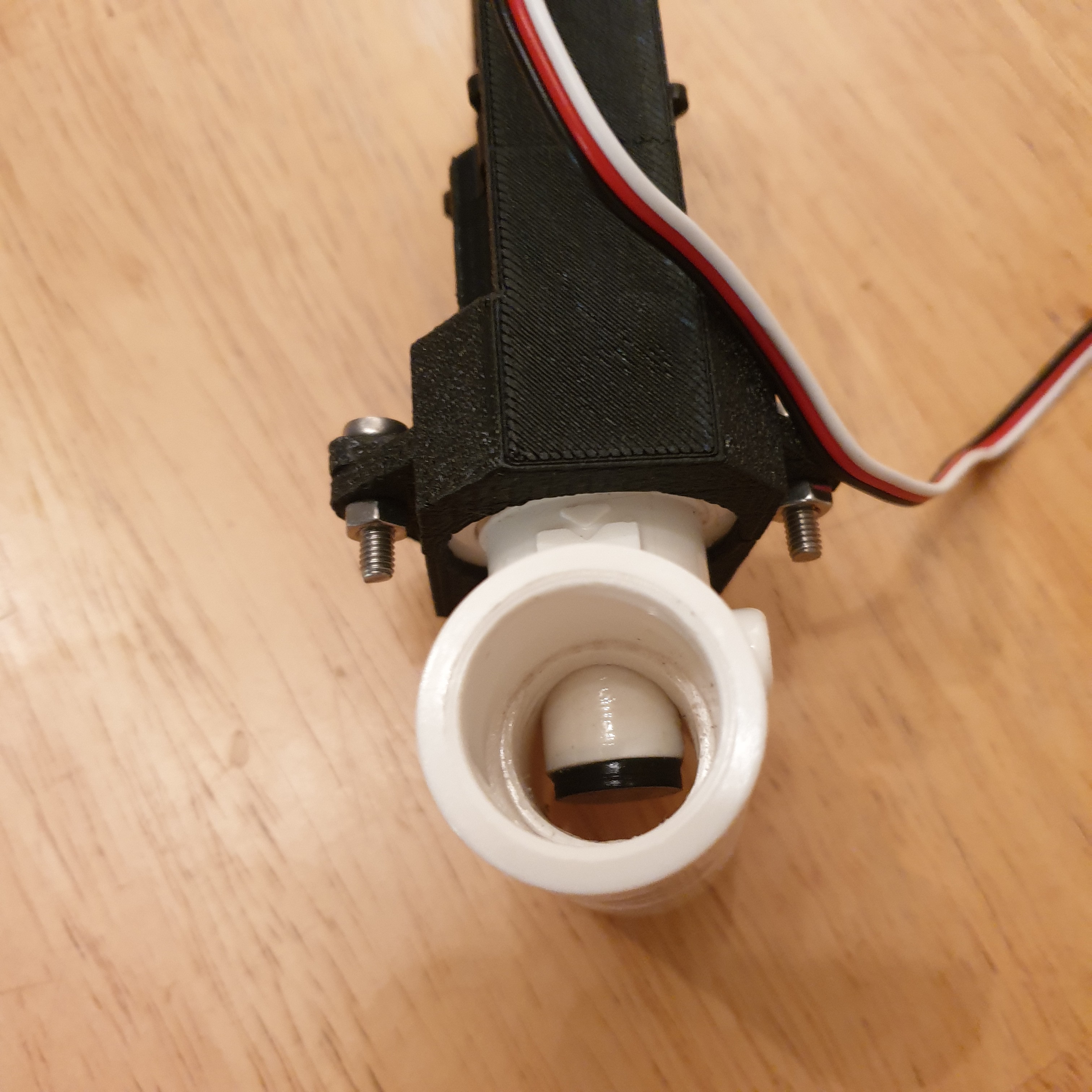

Another challenge with this solution was encapsulating the outside of the valve in the waterproof enclosure while leaving the inside of the valve open to the water environment. This is opposite of how PVC connections are made so I had to make a simple modification to a PVC reducer coupling to make this work. I believe it will still seal properly with PVC glue. The result below shows the servo and outside of the valve on the inside of another larger pipe fitting that will eventually be sealed.

I am looking forward to getting the enclosure fully assembled and run some underwater tests to ensure the mechanism releases properly.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

;)

Are you sure? yes | no