Parts List

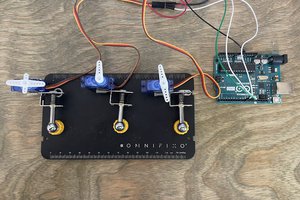

Arduino Uno (or compatible board)

Servo, high-torque 25kg-cm

Power Supply (5V, 4A)

Jumper wires

Screw terminals (x2)

2 potentiometers (10K)

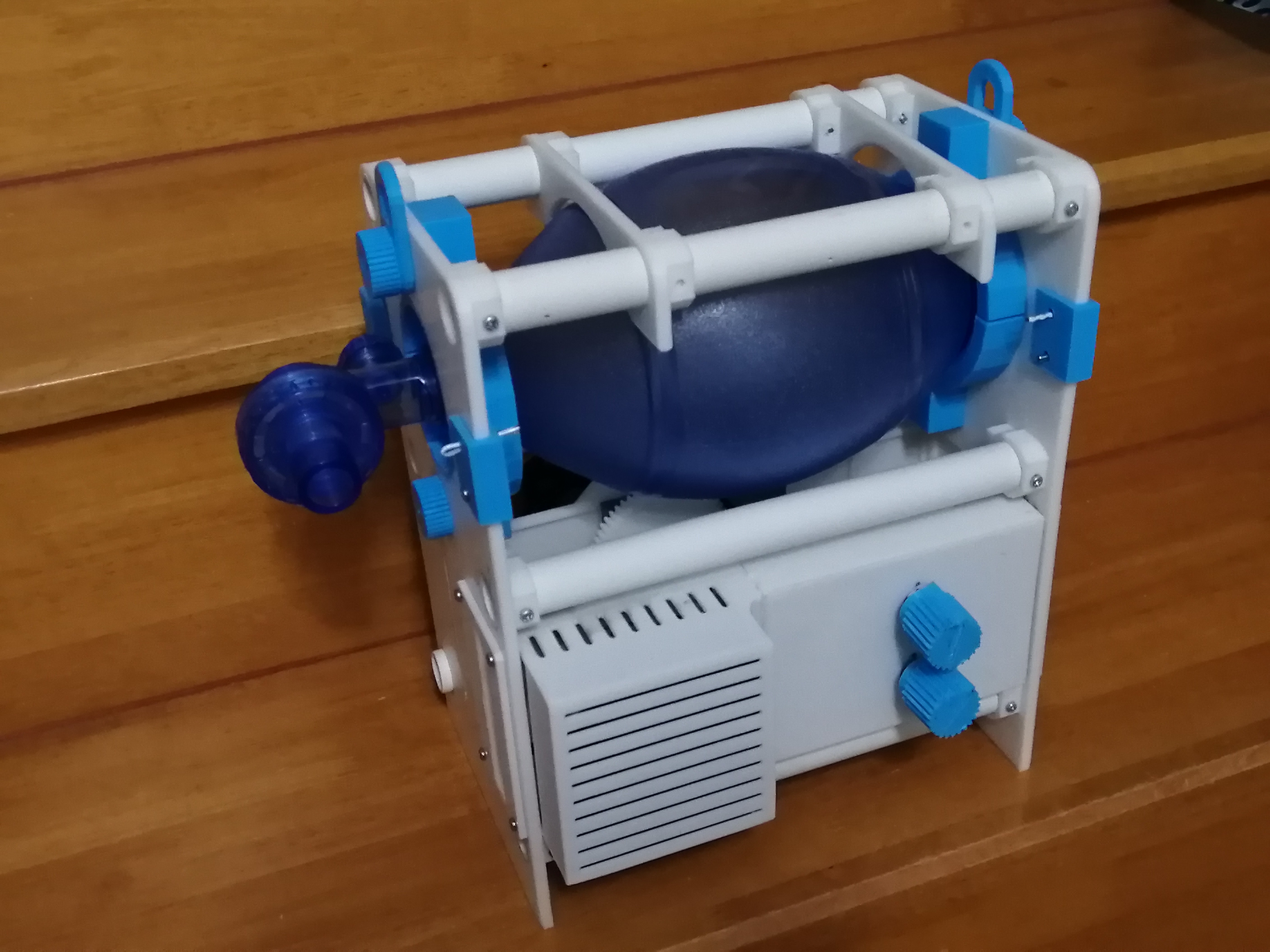

20mm PVC pipe, 1m (cut into x6 235mm sections)

M3 nuts and bolts ( lengths: 10mm, 15mm)

M4 nuts and bolts (lengths: 20mm)

Arduino Code (for quick copying/pasting)

/* Ventilator Control

* Uses Sweep as starting code

* by BARRAGAN

* This example code is in the public domain.

*

* modified 8 Nov 2013

* by Scott Fitzgerald

* http://www.arduino.cc/en/Tutorial/Sweep

*

* modified 25 Apr 2020

* by Wayne Smythe

*

* modified 1 Jun 2020

* by Brian Berletic

* servo pauses between delays in the resting position rather than compressing the bag

*

* Requirements: 2 adjusting knobs

* Air Volume Selection: 25%, 33%, 50%, 75%, 100% - determined by servo end position

* Rate of Compression: 6, 10, 14, 18, 24 cycles per minute (determined by delay)

* This requires 2 variable resistors connected to 5V and GND and to ANALOG IN pins 0 and 1 - I used 10K

*/

#include <Servo.h>

#define DEBUG 1

Servo myservo; // create servo object to control a servo

int pos = -70; // default -70: initialize the servo start position

int RateDelay = 2000; // default 2000: The delay used between strokes

int StopPosition = 150; //default 150: The stop position of the servo determining the volume of air

int potpinVol = 0; // analog pin used to connect the 10K potentiometer for volume

int potpinRate = 1; // analog pin used to connect the 10K potentiometer for rate

int val0; //variable to read the value from the analog pin

int val1; // variable to read the value from the analog pin

void setup() {

#ifdef DEBUG

Serial.begin(9600); // BaudRate for debug

#endif

myservo.attach(9); // attaches the servo on pin 9 to the servo object

}

void loop(){

/* Number of Compressions per Minute

* rate of compression: 6, 10, 14, 18, 24, cycles per minute

* read the position of the Rate knob to determine the rate

*/

val1 = analogRead(potpinRate); // reads the value of the potentiometer

val1 = map(val1, 0, 1023, 0, 100);

#ifdef DEBUG

Serial.print("\t Delay map value = ");

Serial.print(val1);

#endif

if (val1>=0 && val1<=20)

{

RateDelay = 10000; // default 10000

}

else if(20<val1 && val1<=40)

{

RateDelay = 6000; // default 6000

}

else if(40<val1 && val1<=60)

{

RateDelay = 4286; // default 4286

}

else if(60<val1 && val1<=80)

{

RateDelay = 1500; // default 3333

}

else

{

RateDelay = 1000; // default 2500

}

#ifdef DEBUG

Serial.print("\n RateDelay = ");

Serial.print(RateDelay);

#endif

val0 = analogRead(potpinVol);

#ifdef DEBUG

Serial.print("\t pot value = ");

Serial.print(val0);

#endif

val0 = map(val0, 0, 1023, 0, 180);

#ifdef DEBUG

Serial.print("\t map value = ");

Serial.print(val0);

#endif

if (val0>=0 && val0<=36)

{

StopPosition = 30;

}

else if(36<val0 && val0<=72)

{

StopPosition = 60;

}

else if(72<val0 && val0<=108)

{

StopPosition = 90;

}

else if(108<val0 && val0<=144)

{

StopPosition = 120;

}

else

{

StopPosition = 170;

}

#ifdef DEBUG

Serial.print("\n Stop Position = ");

Serial.print(StopPosition);

#endif

for (pos = -70; pos <= StopPosition; pos += 1) { // goes from 0 to 180 degrees

myservo.write(pos);...

ProgressTH

ProgressTH

Smalls

Smalls

engineerkid1

engineerkid1

theschlem

theschlem