Summary

After some thought, I synthesized the following main functions and capabilities:

- The future device has to control audio on the PC's OS, not with just a potetiometer;

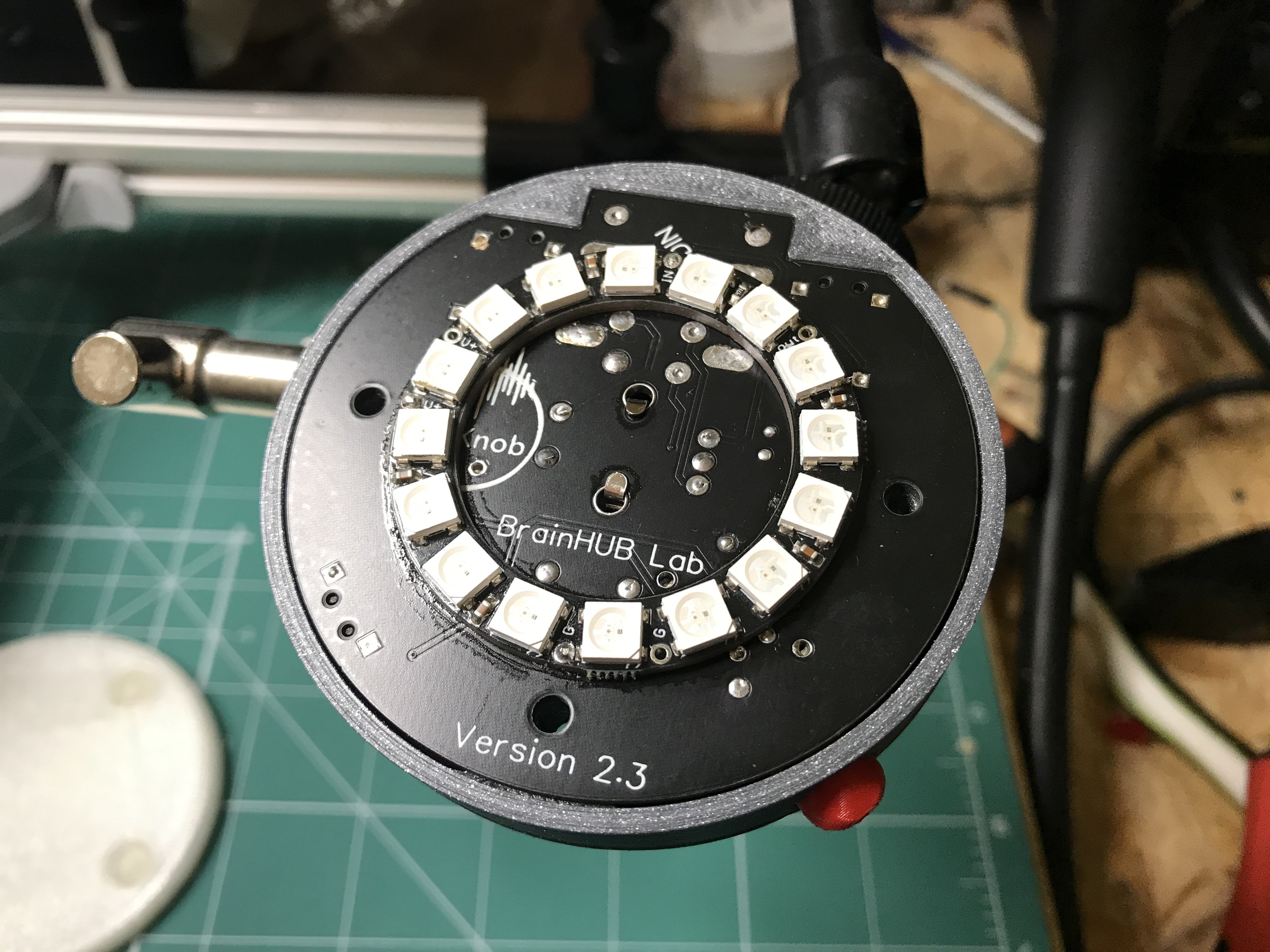

- I want to have some nice looking RGB led lights ;

- The future device has to be easily repeatable;

- The future device has to have the capability for more functionality - for example scrolling;

To be honest, the presented version is already the second one, but I will describe it anyway because I loose all photos from the first one.

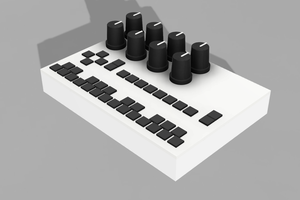

So, the final device has the following functions:

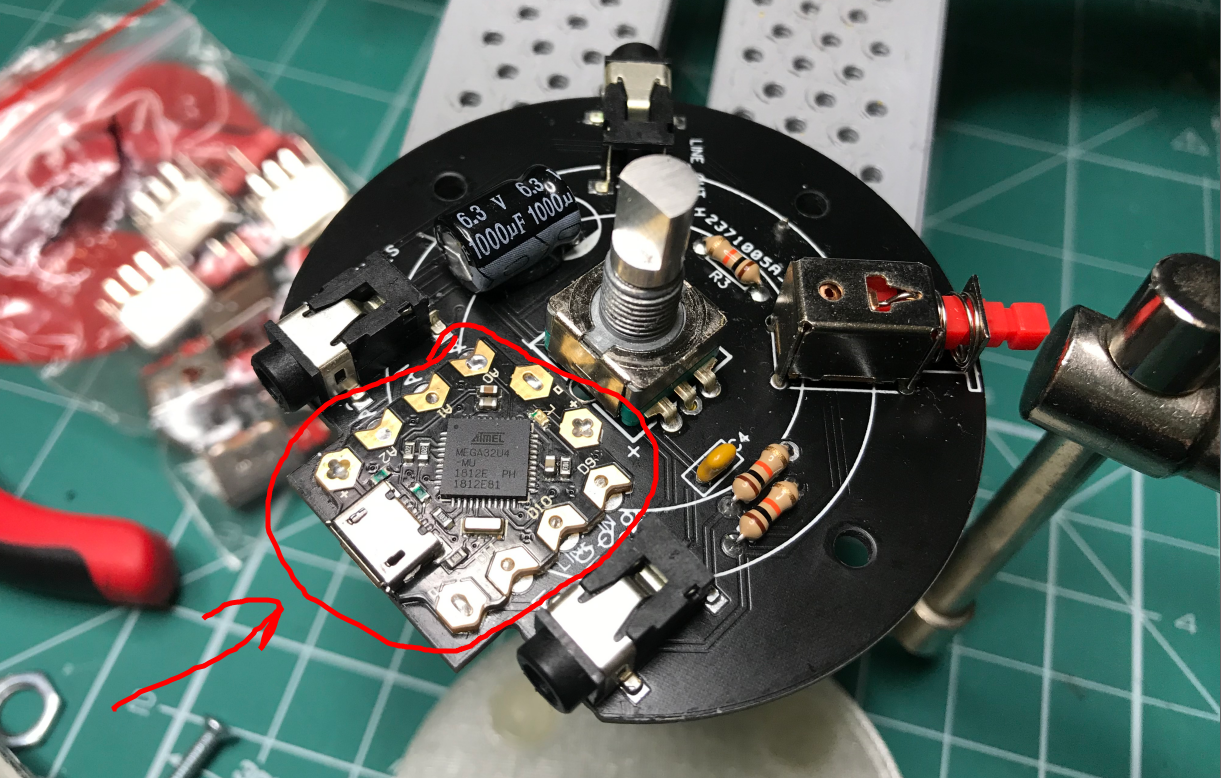

- Audio control on OS by using the awesome HID library;

- After-a-double-click the knob enters to the scroll mode;

- There are two outputs and one input, and a physical switch between them;

- Several LED backlight modes inclusive responsive to music (like VU meter);

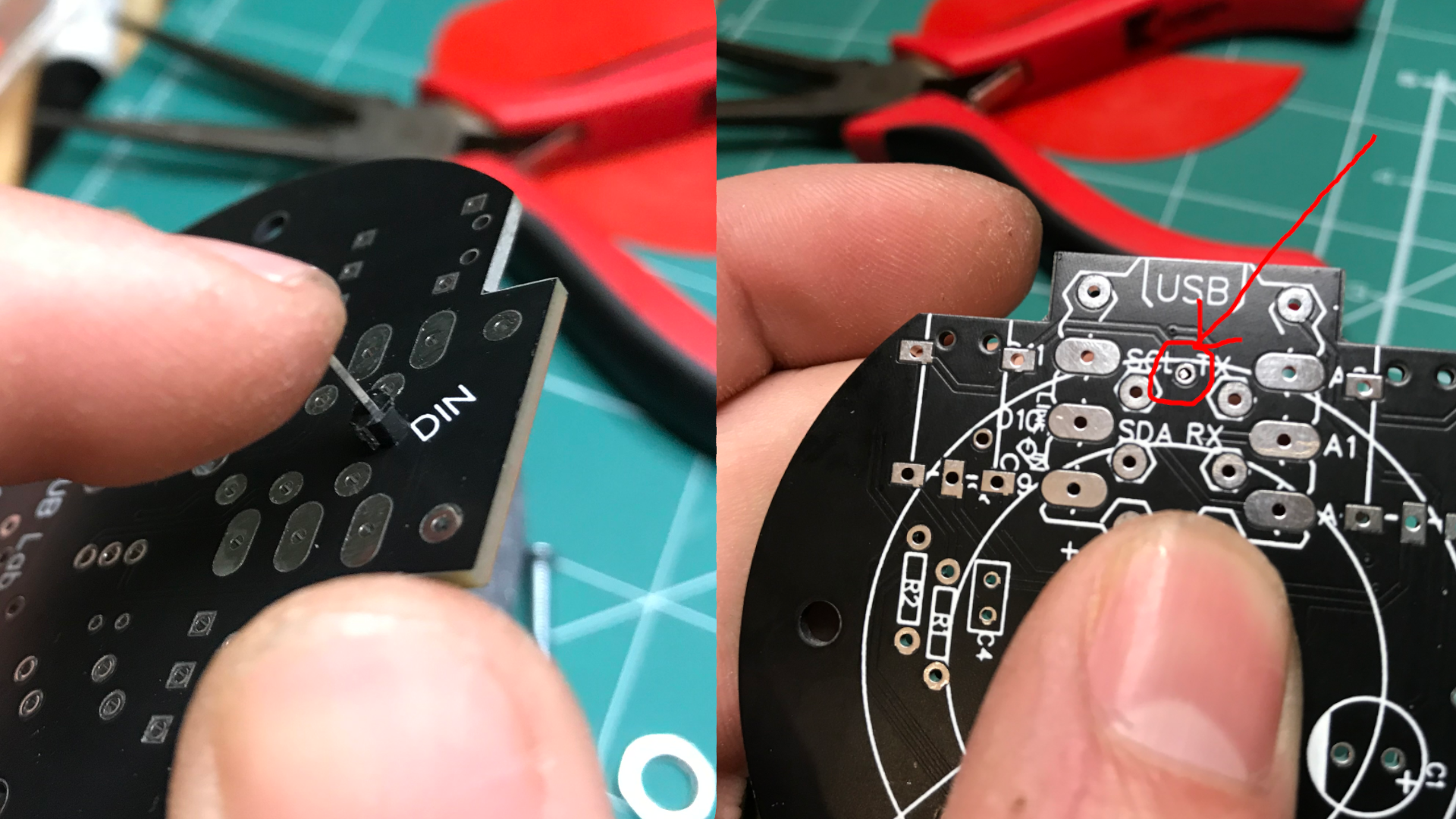

- The code and the hardware used are simple and can be easily modified;

- And of course, the knob is made of concrete;

BrainHUB Lab

BrainHUB Lab

Vojtěch Vosáhlo

Vojtěch Vosáhlo

Adam Mansour

Adam Mansour

I really appreciate your design considerations. I'd been considering a similar device but hadn't decided on hardware/form. This is gorgeous, thanks for sharing.