Face Mask Disinfection Device

UV-C / Heat, Arduino controlled, face-mask disinfecting device for Coronavirus (SARS-CoV-2)

This is an open source project shared under Creative Commons

“Attribution-NonCommercial-ShareAlike” CC BY-NC-SA

Disclaimer: This document falls under the "Good Samaritan Law".

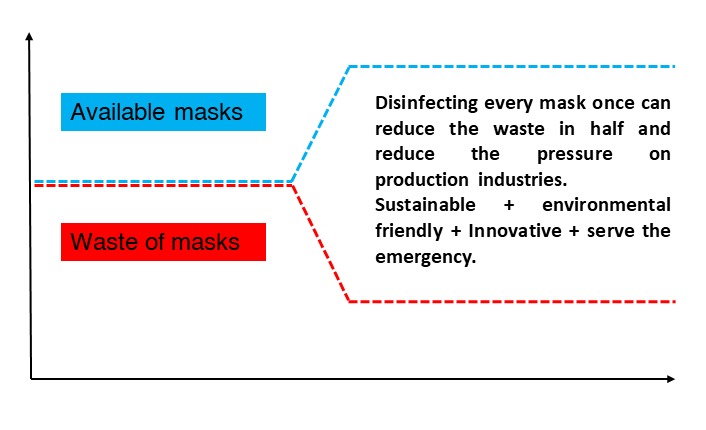

Problem Statement

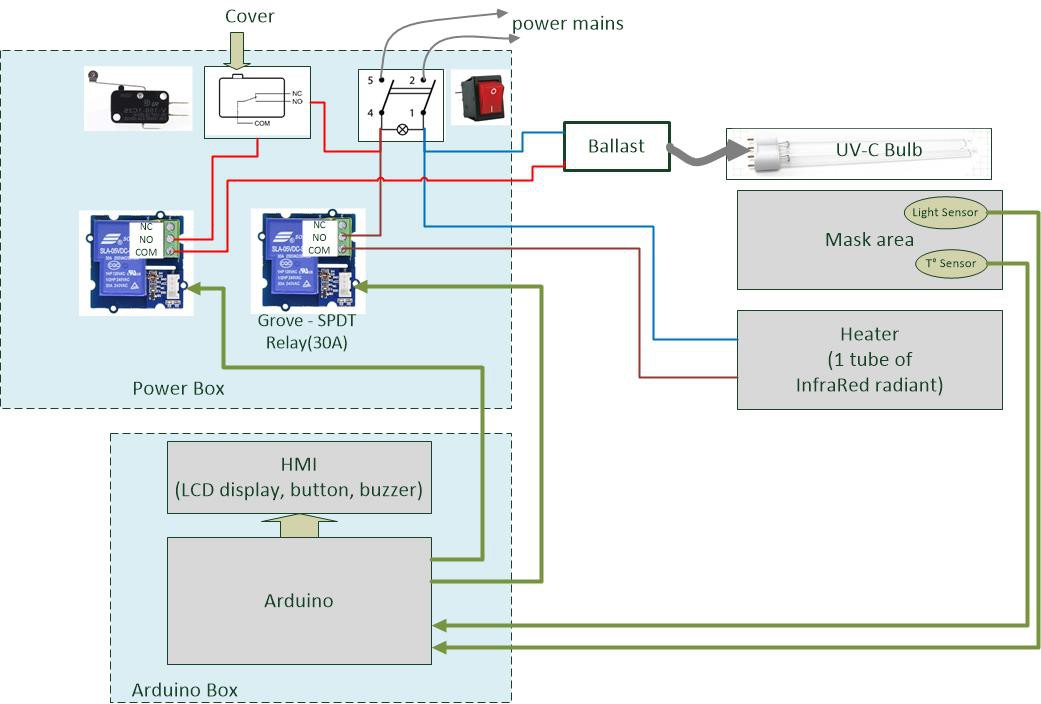

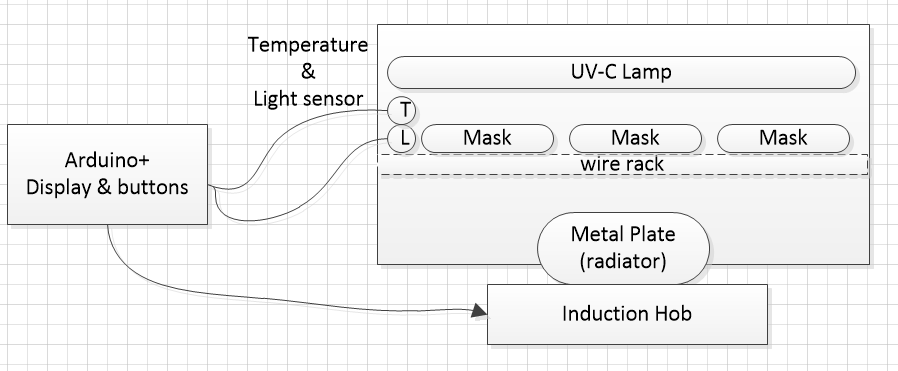

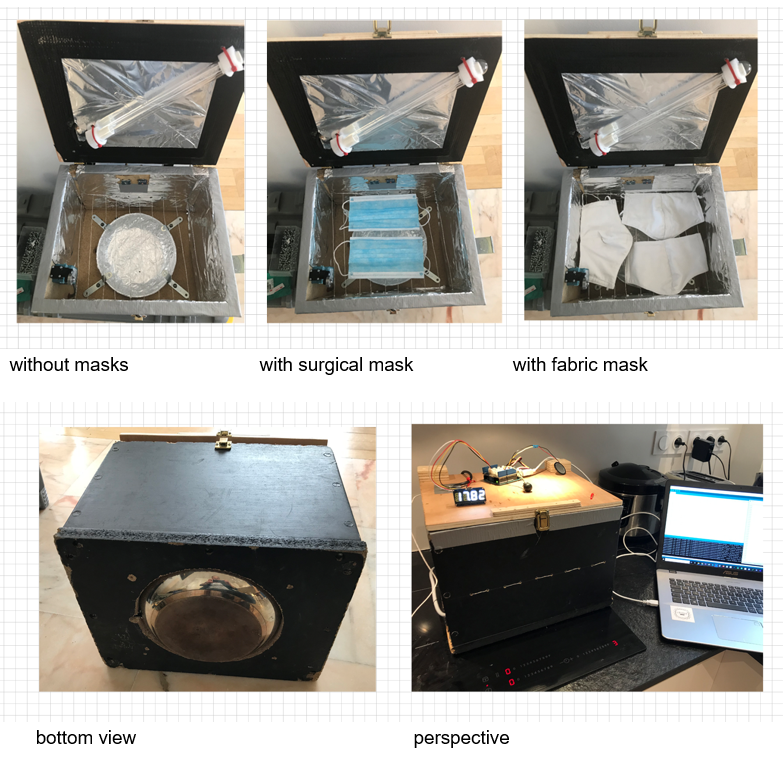

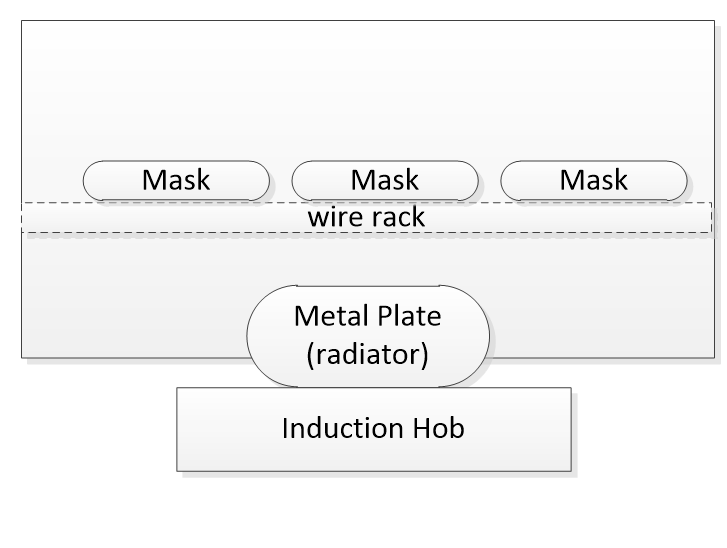

This device is a low budget and portable solution- that effectively uses UVGI and dry heat to disinfect face masks from SARS-CoV virions. The make of the device is simplified to enable easy production by people who have access to a maker space.

Version 1

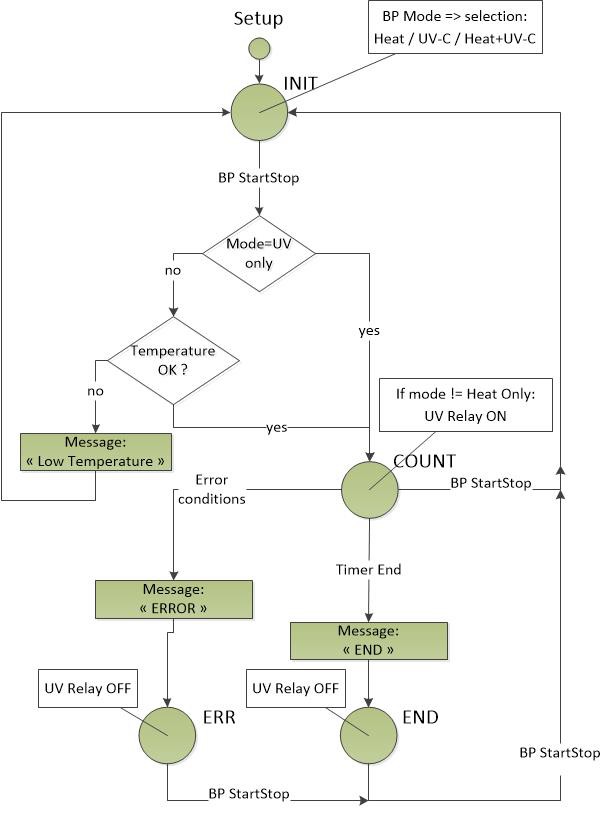

•Dual protection: UV-C + dry heat

•Alarm: indicator for temperature differences.

•Affordable and easy to make.

Version 2

•Dry heat from infrared – cost effective and accessible to all.

•Can disinfected face shields as well.

•Can choose the combinations b/w UVC and Dry heat – or just one of them.

•Can accommodate more masks.

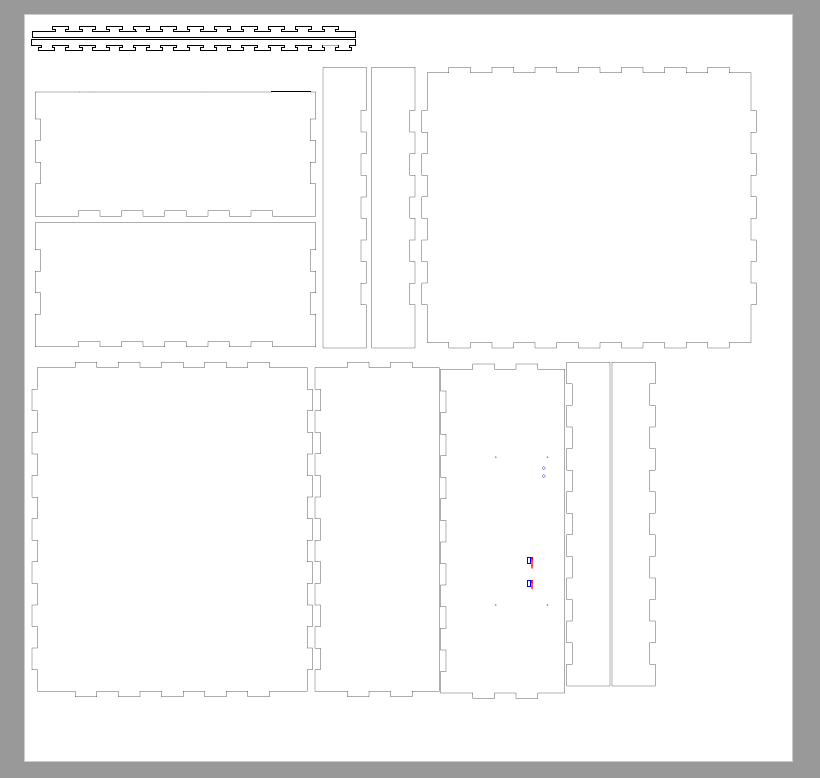

•Opensource – downloadable CNC, laser design files.

Published on:

- https://create.arduino.cc/projecthub/needlab/face-masks-disinfection-device-needlab-3ed2f5

- https://project.seeedstudio.com/needlab/face-masks-disinfection-device-needlab-3ed2f5

- https://www.seeedstudio.com/blog/2020/04/14/covid-19-series-face-mask-disinfection-device-using-uv-c-and-dry-heat-by-team-needlab

- https://www.hackster.io/needlab/face-masks-disinfection-device-needlab-3ed2f5

- https://makezine.com/2020/03/27/make-these-projects-to-fight-covid-19-right-now/

- https://makeprojects.com/project/face-masks-disinfection-device

- https://projetsdiy.fr/covid-19-makers-fablabs-repertoire-projets-lutter-coronavirus/#Sterilisation_UV

- https://www.makery.info/2020/04/10/covid-19-vers-une-solution-diy-de-desinfection-des-masques-ffp2/

- https://www.elektormagazine.com/labs/uv-c-heat-arduino-controlled-face-mask-disinfecting-device-for-coronavi

- https://www.open-electronics.org/guest_projects/face-masks-disinfection-device-needlab/

Github: Files to make the V2 of the Face mask disinfection device.

https://github.com/NeedLab/face-mask-disinfection-device

This publication explains in detail the method to build both V1 and V2 of the Face Mask disinfection device.

Sameera Chukkapalli

Sameera Chukkapalli

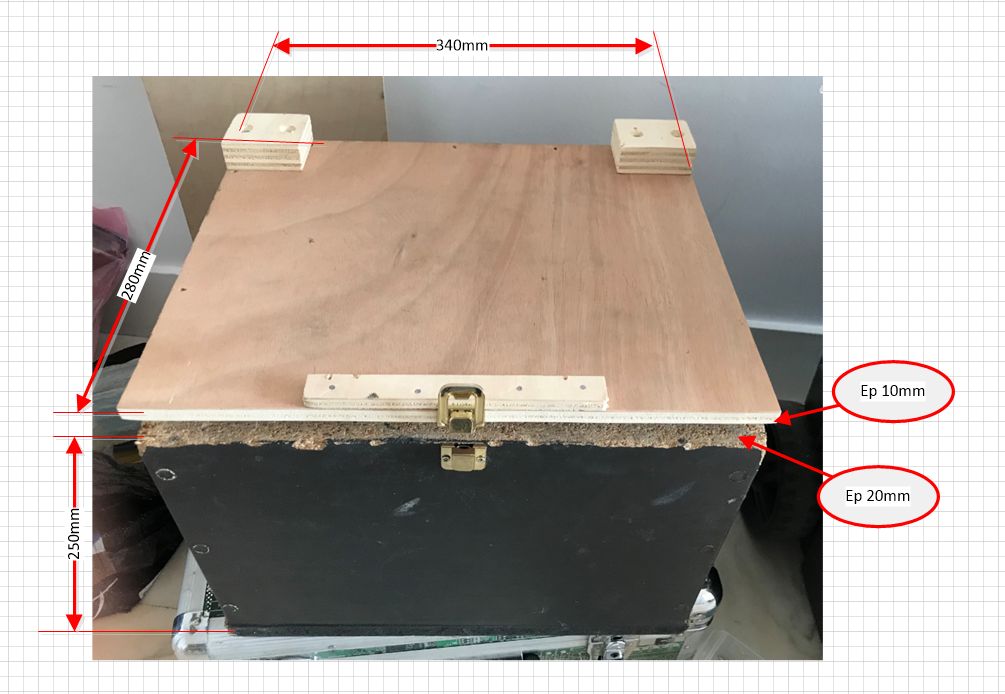

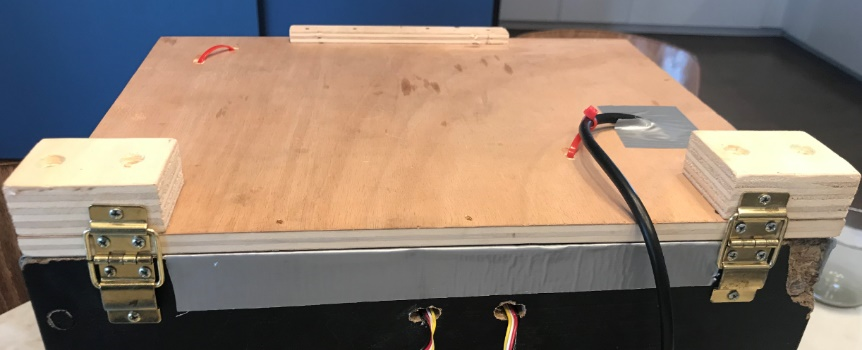

A small lock was used to ensure the closer of the cover.

A small lock was used to ensure the closer of the cover.

mcThings

mcThings

Jay Phantom

Jay Phantom

João Assunção

João Assunção

Anteneh Gashaw

Anteneh Gashaw