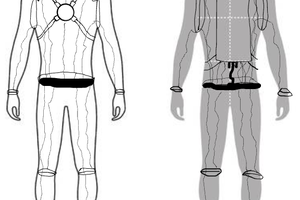

i. Concept- Is the project creative, original, functional, and pushing boundaries? Does the project effectively address the selected challenge?

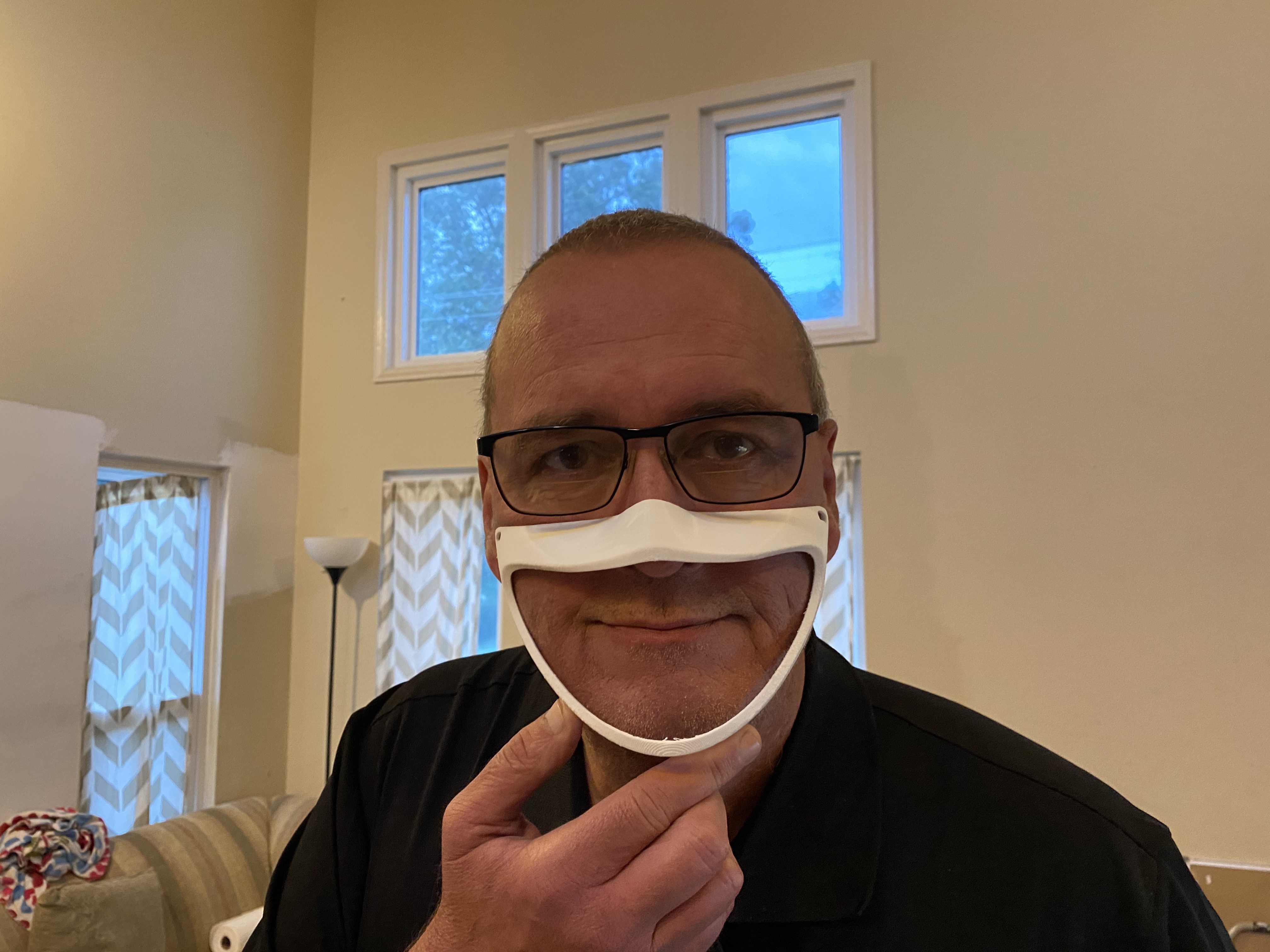

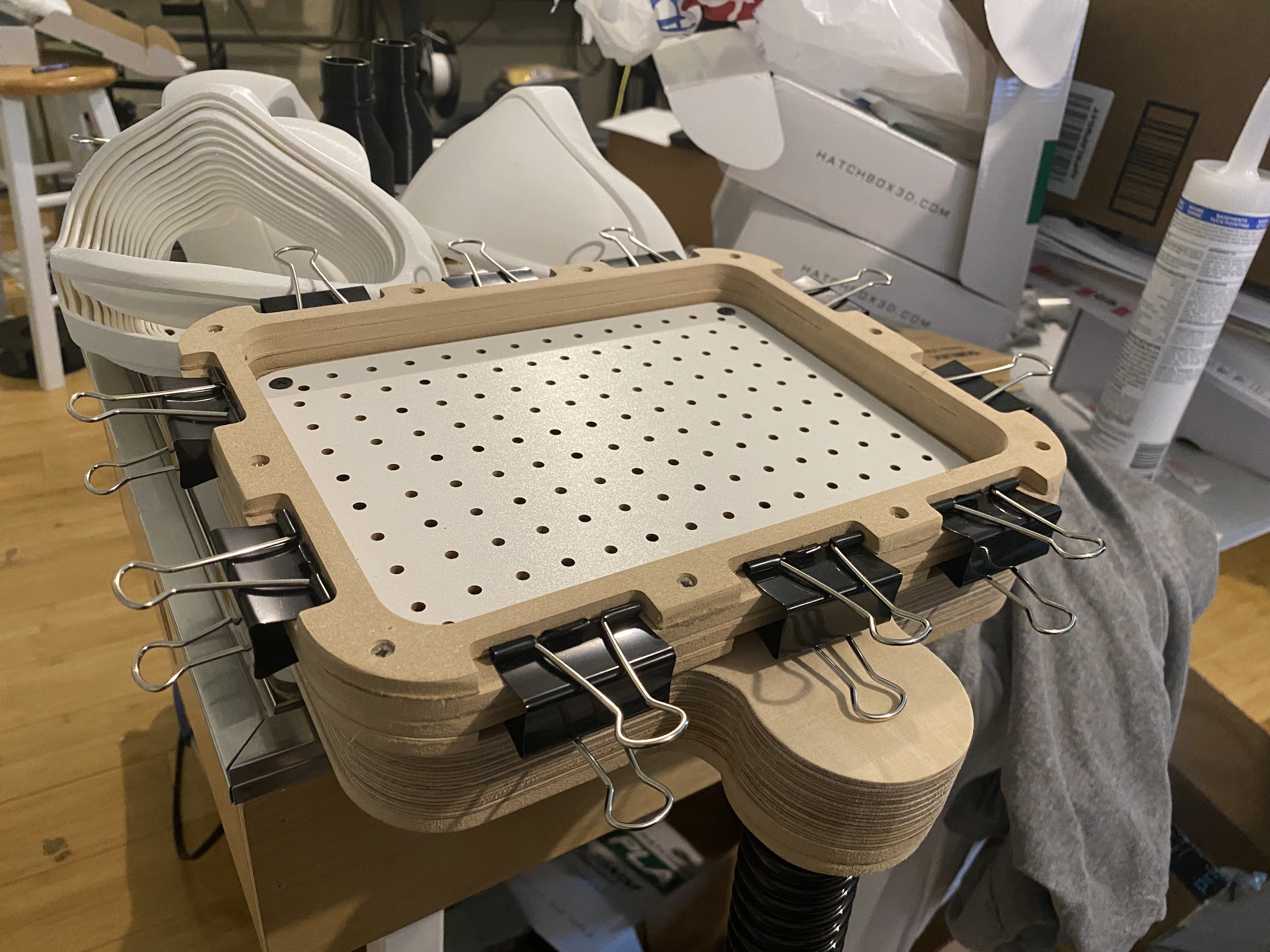

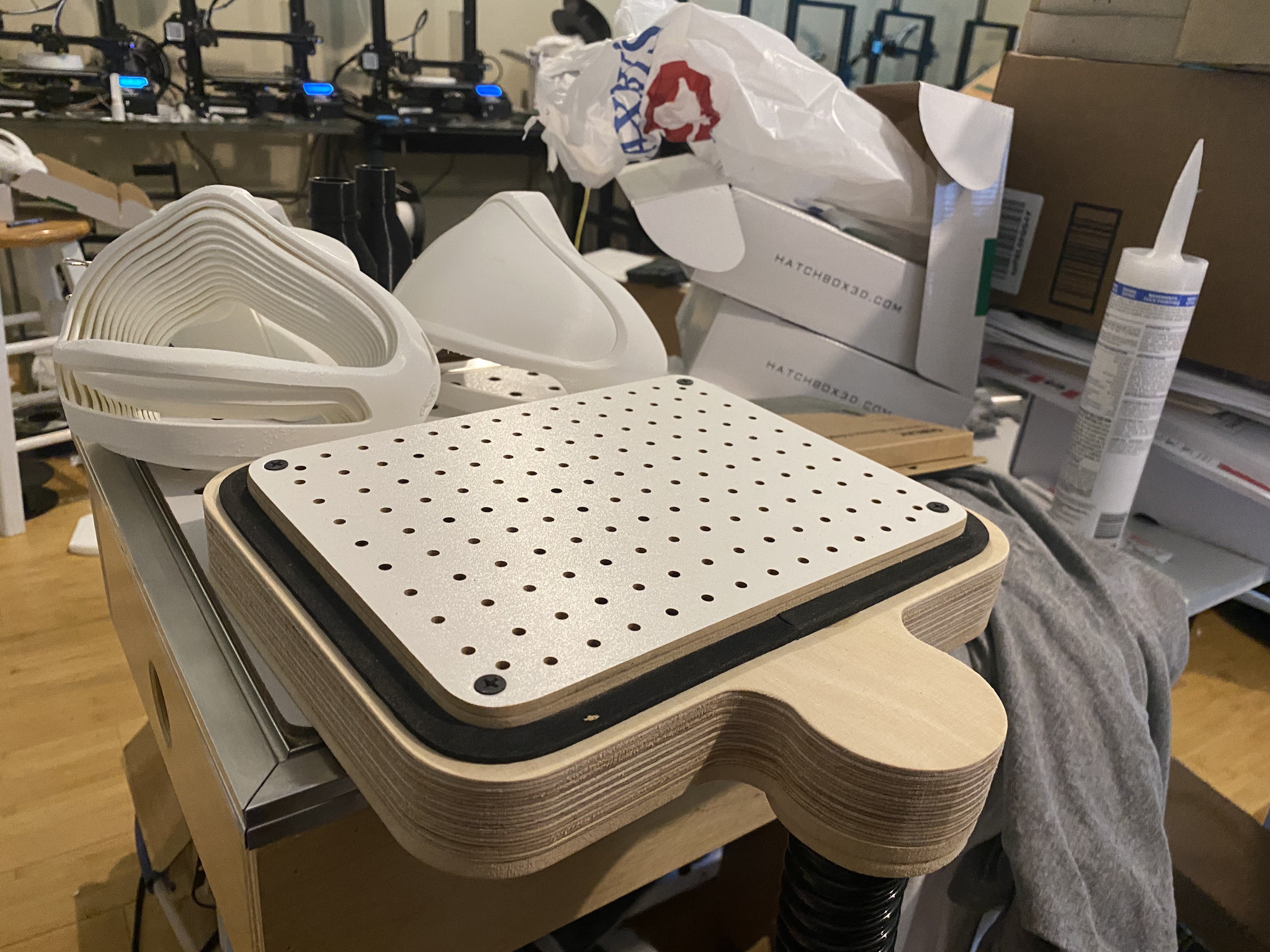

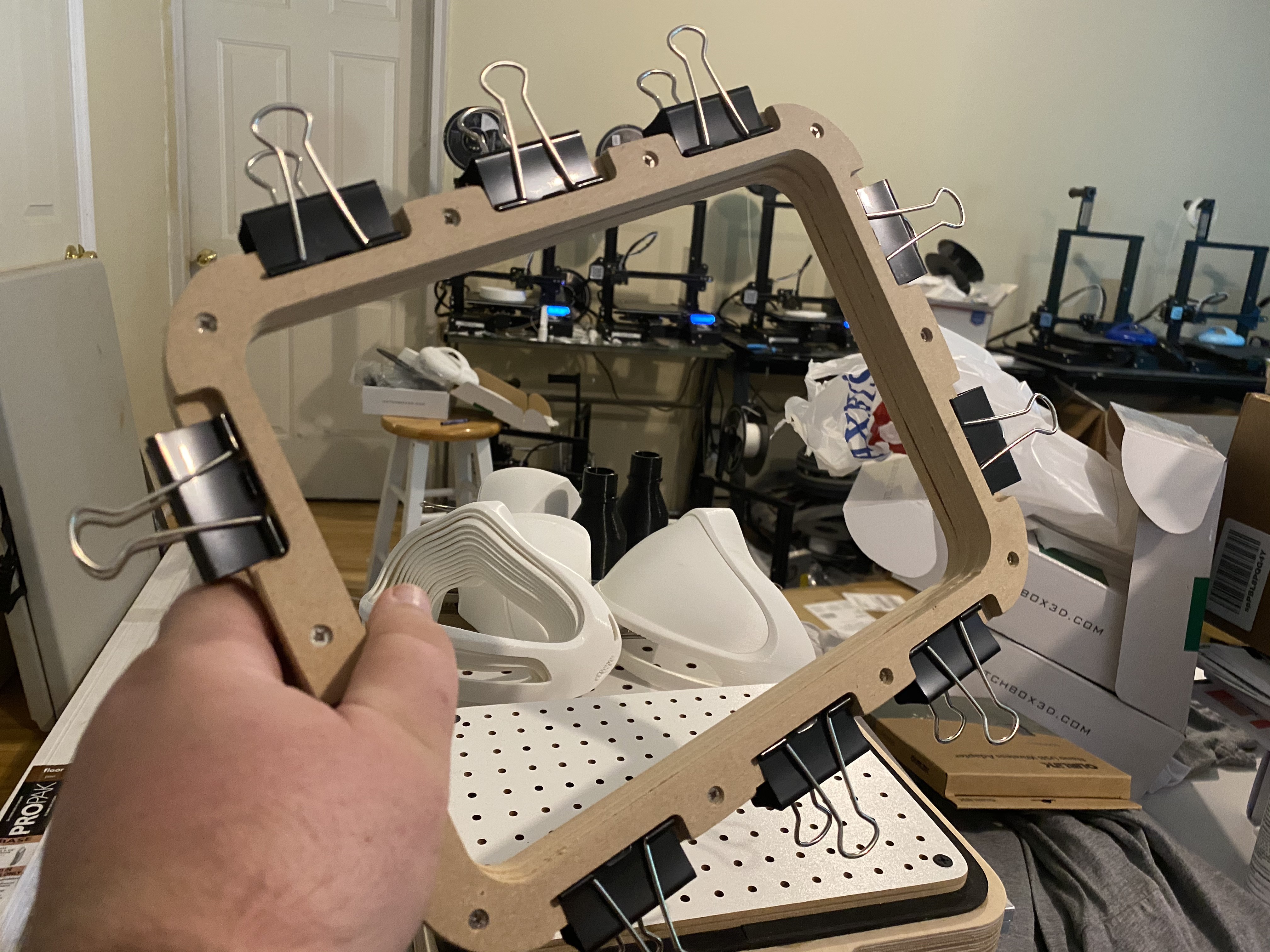

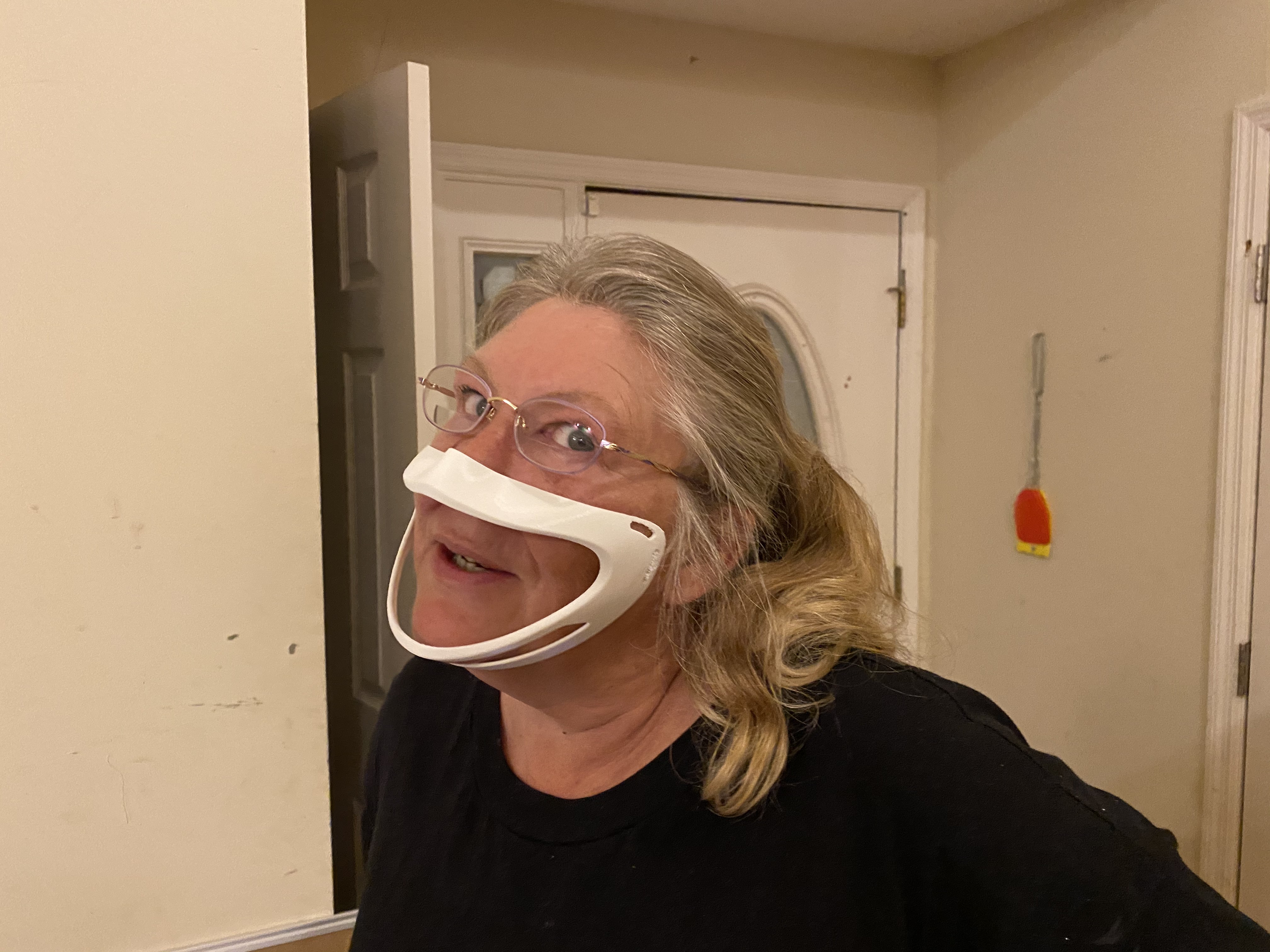

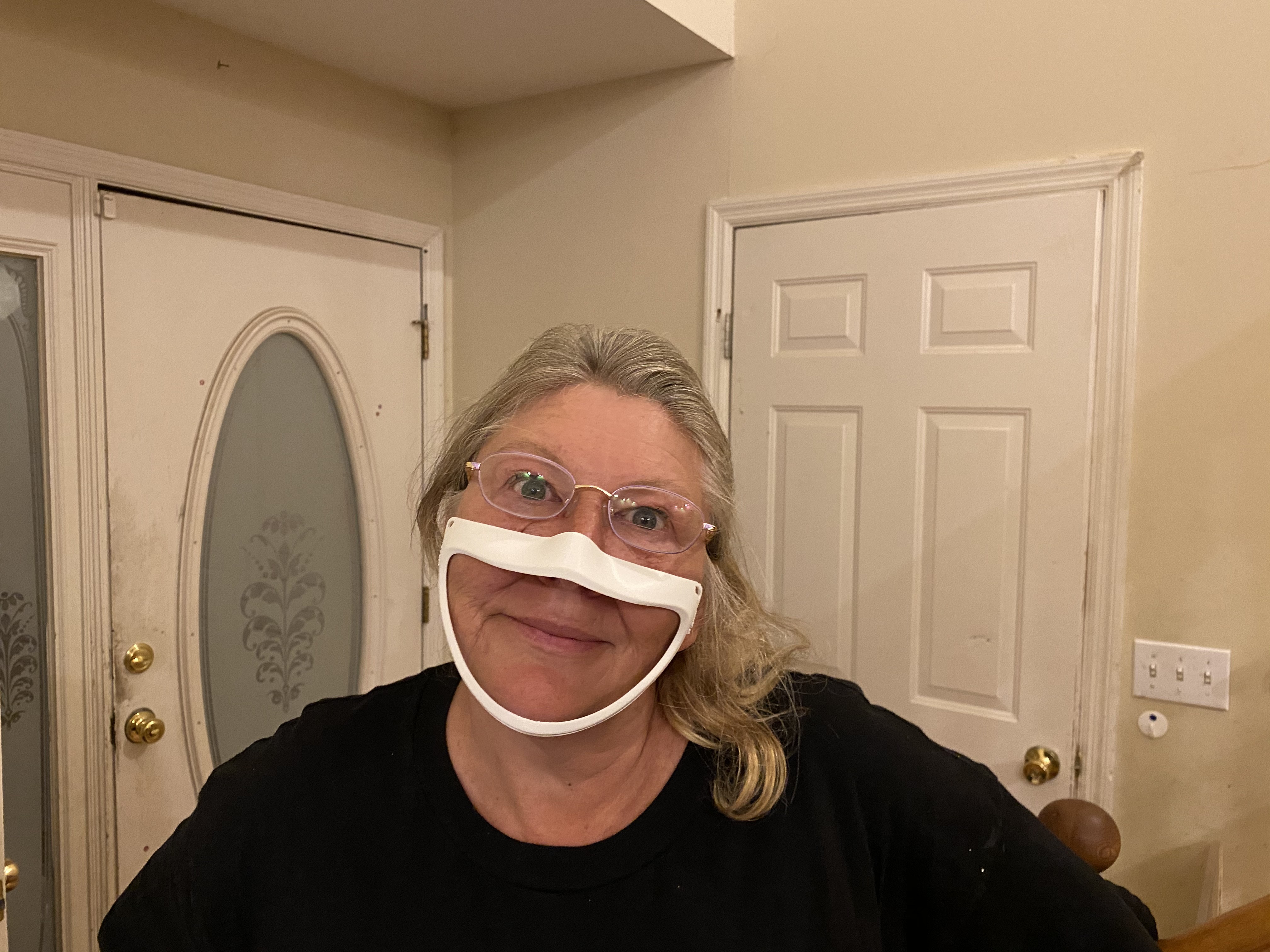

YES , Cerebral Palsy Adaptive Technologies, Expression and communication. Our project pushes the boundaries of how we consider PPE to look and be used. Enhanced fitment, functionality and re usability is a valuable feature. Multiple sizes of vacuum bucks allows for a variety of sizes even in children sizes if you will that a standard mask does not fit.

ii. Design- Is there a depth of design detail available (like a system design, CAD models, project test methods, etc.)? Is there base-level planning for the functionality (e.g., functional block diagram, list of specifications and descriptions of how they will be met, etc.)? How user-friendly is the design?

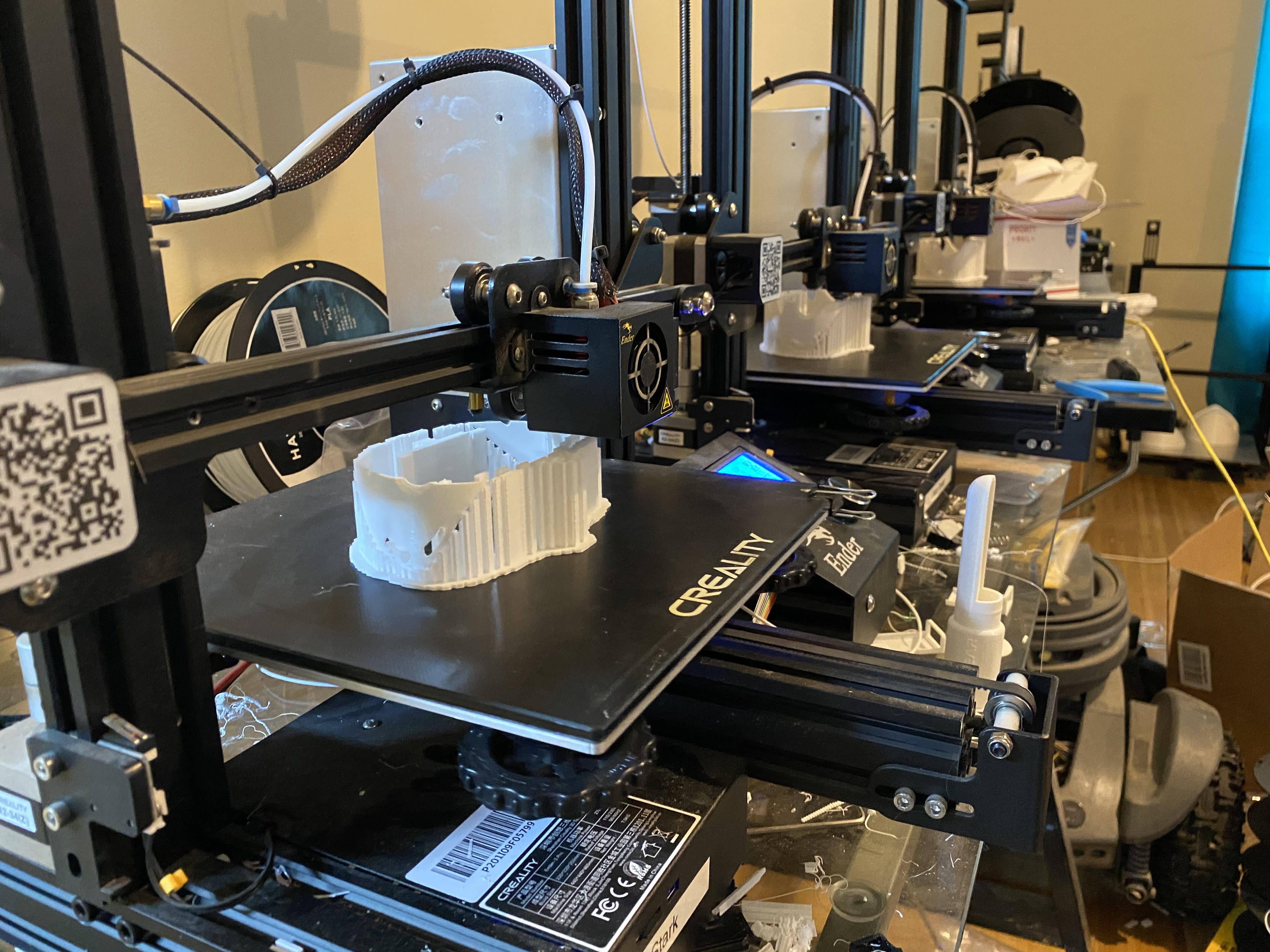

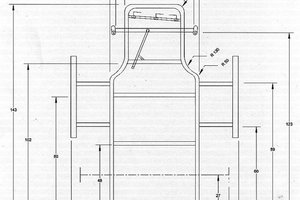

The design is user friendly and light. Simplicity is important for effective duplication and re usability. Every step of the project has coordinating files saved for them.

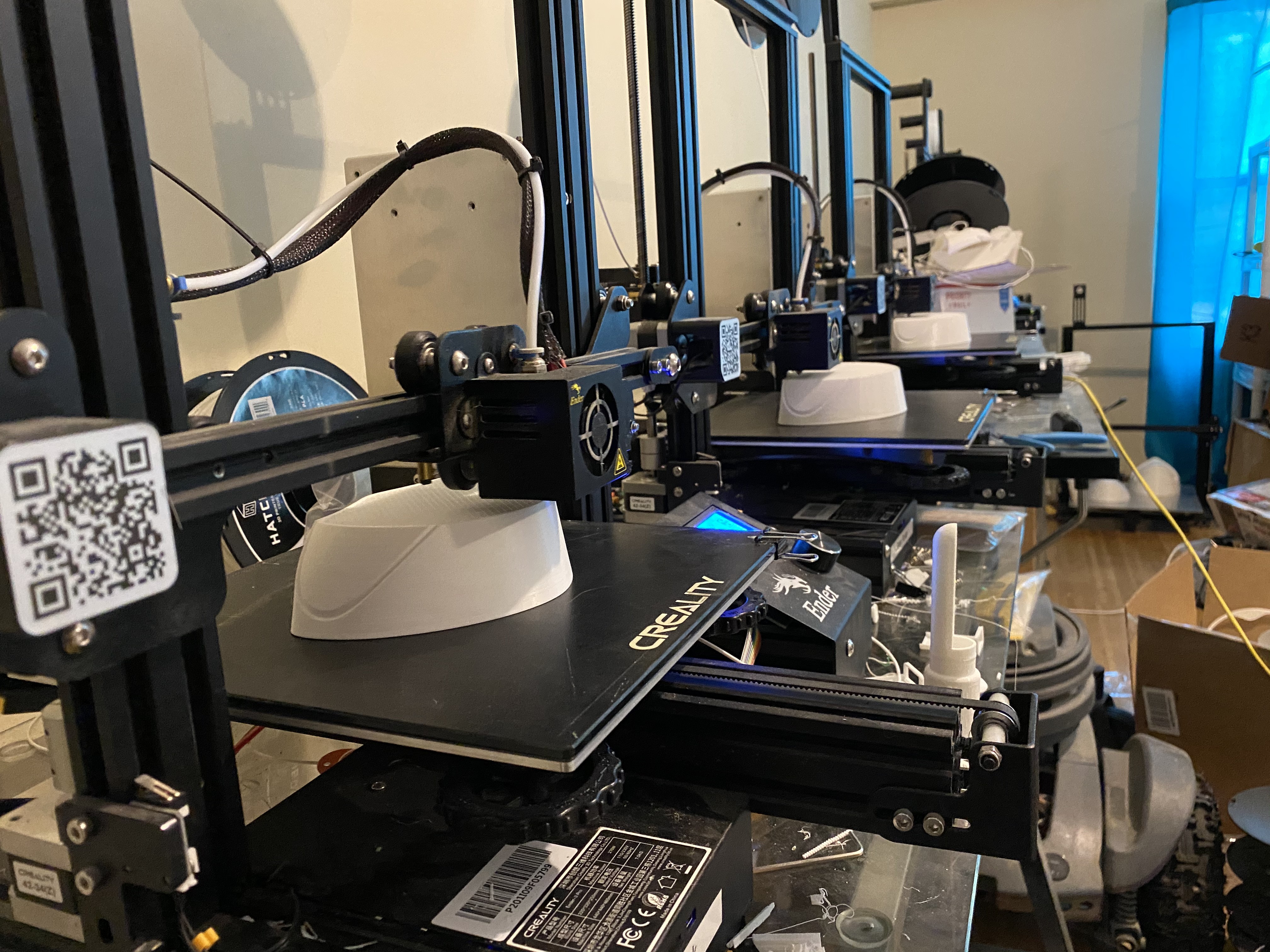

iii. Production- Is the project realistically reproducible (taking into consideration necessary materials, skills, and production processes)? Are the manufacturing processes detailed? Are those processes realistic for scalability?

The Clear View mask was intentionally designed for rapid reproduction in mind. School kids will be going back to school soon and this could be very valuable.

iv. Benchmark- How well is the project impact and viability demonstrated? Are estimated costs realistic? How well does the project improve upon other currently available solutions?

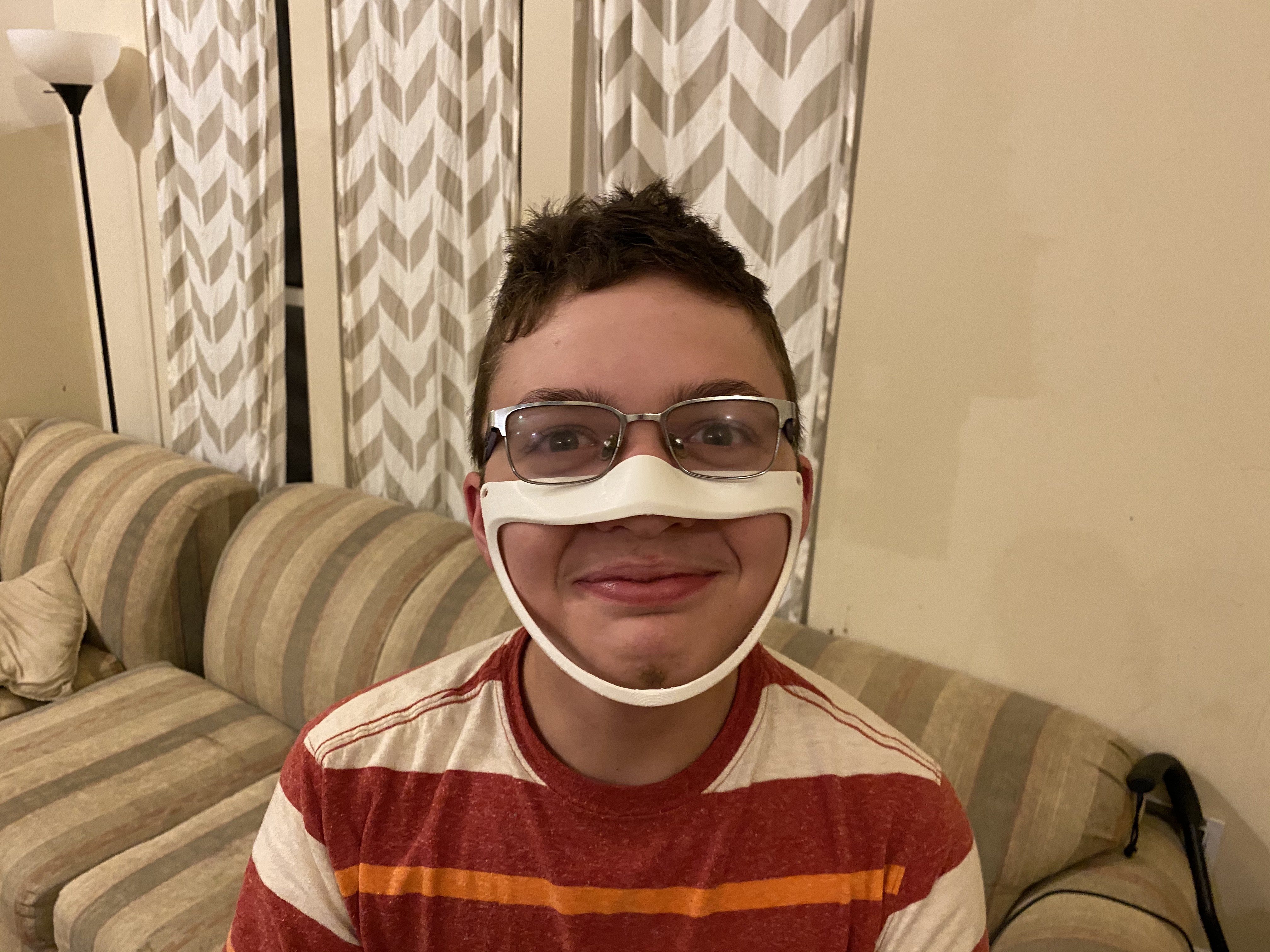

I will make a video showing the parts and how it is produced, as well as a variety of sizes on my family as a example.

v. Communication- How thoroughly have the Final Round requirements been completed? How well documented is the project? How “open” is the design?

NOT YET, but the project steps are being documented as I go and no doubt will be very thorough.

Josh Starnes

Josh Starnes

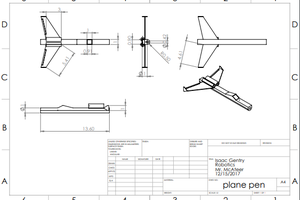

Isaac S. Gentry

Isaac S. Gentry

Giovanni Leal

Giovanni Leal

Adam Jensen

Adam Jensen

P4130

P4130

Any chance of sharing the STL files for the mask?