The last two weeks I have been working on redesigning the main axis of WinDIY. The old axis worked, but had two problems.

The first thing, it was/is quite loud. I used angular ball bearings because they are actually perfect for absorbing forces in the axial and radial direction. Conveniently/unfortunately, the gap (between the bearing components) is adjustable with these. That means you can decide by the dimensions of the housing parts how close together the individual bearing parts are.

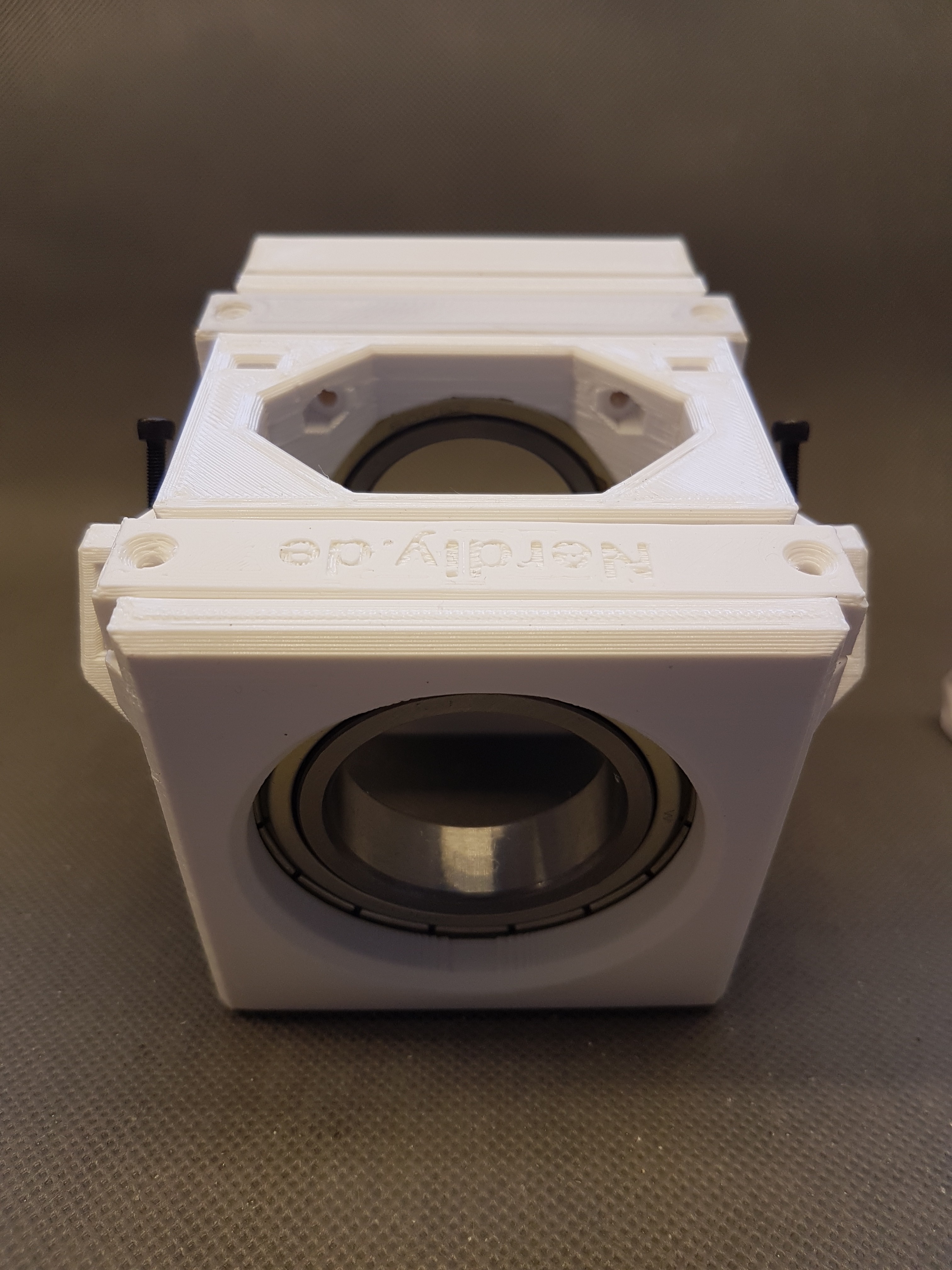

Unfortunately I never managed to set these properly. (Maybe I also lack the experience with these kind of bearings.) Also in order to not make the structure even more complicated, I decided to replace the angular ball bearings with radial bearings. These can take about 10% of the radial load in the axial direction. So if you install a radial bearing that is oversized accordingly, it should also fit with the forces in the axial direction. :)

(And I am sure that I will find another use for the - now remaining - angular ball bearings.: D)

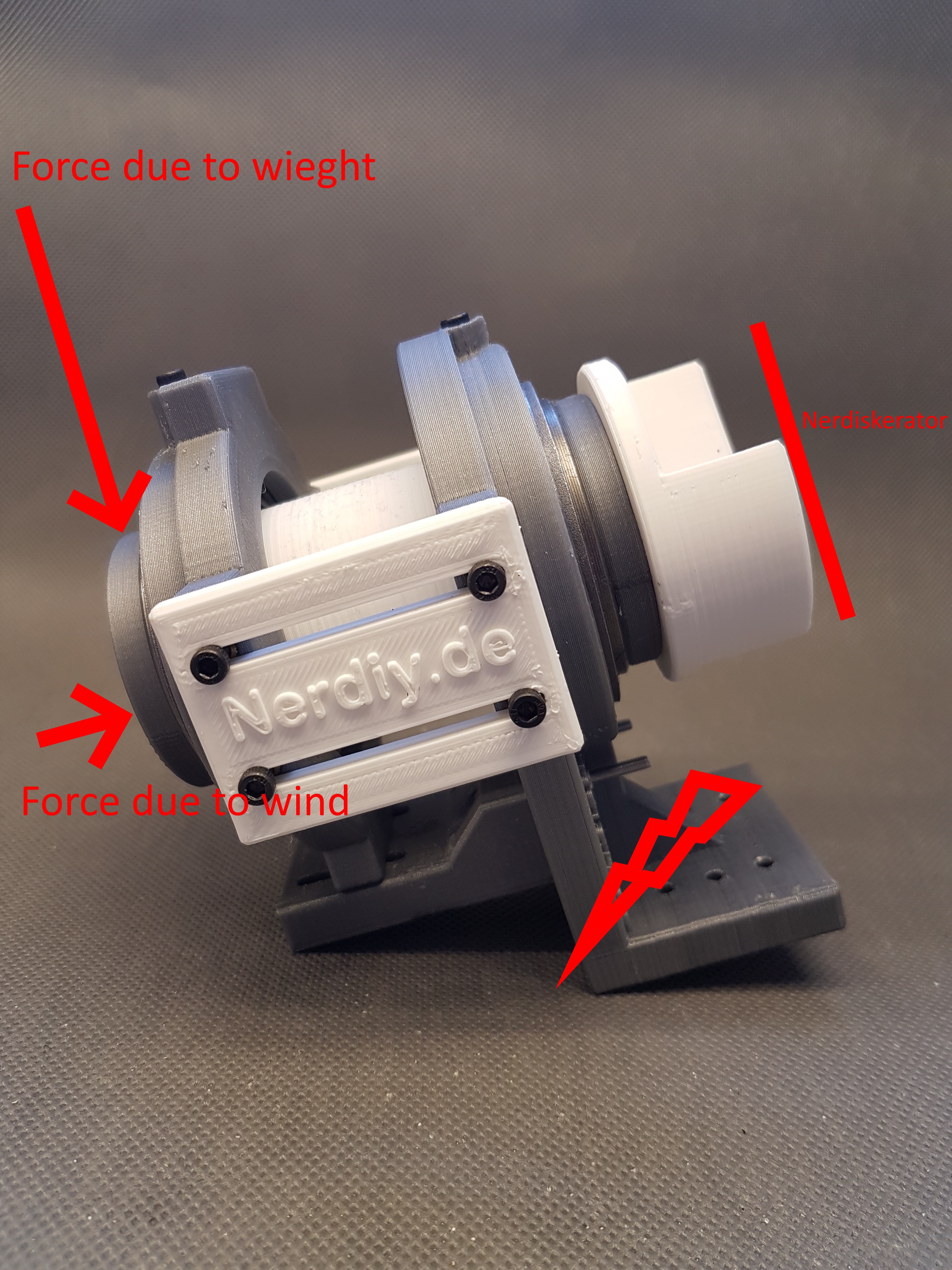

The second problem is that the old connection between the shaft mount and the rest of WinDIY consists of 3D printed parts. I suspect that this will not last in the long run because this point is exposed to changing forces from the front (due to wind pressure) and the weight of the wings and hub.

I tried to show what I suspect in the picture. The whole 3D printed structure will experience forces in the direction of the arrows. Plus vibrations from the components, which may not be perfectly balanced. All of these forces are ultimately dissipated into the rest of Windiy 's structure via the spot marked with the flash.

Therefore the flash marks the point where I assume that this structure will not last very long.

That's why I decided on a redesign, which you can see below. :)

The new design

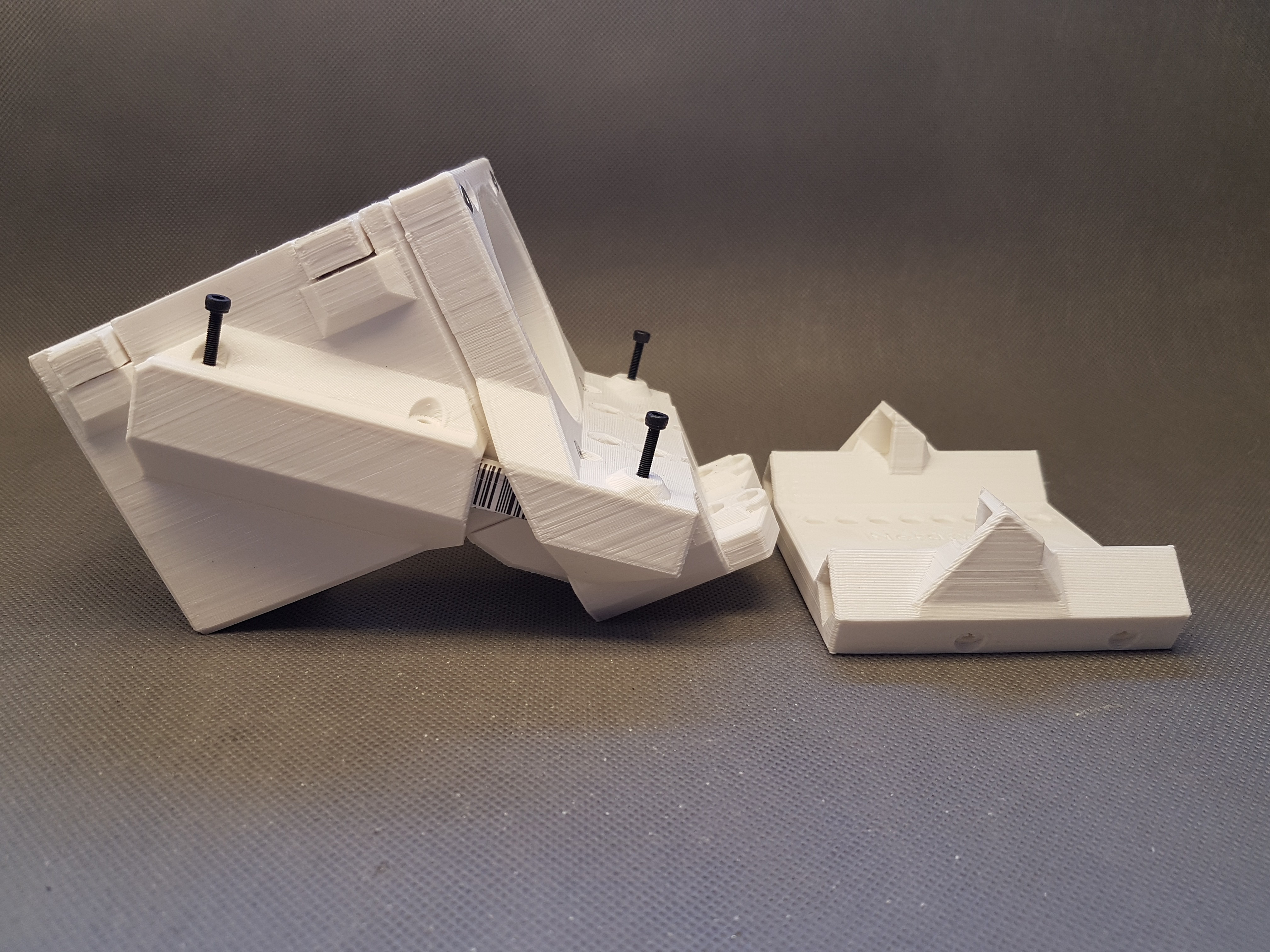

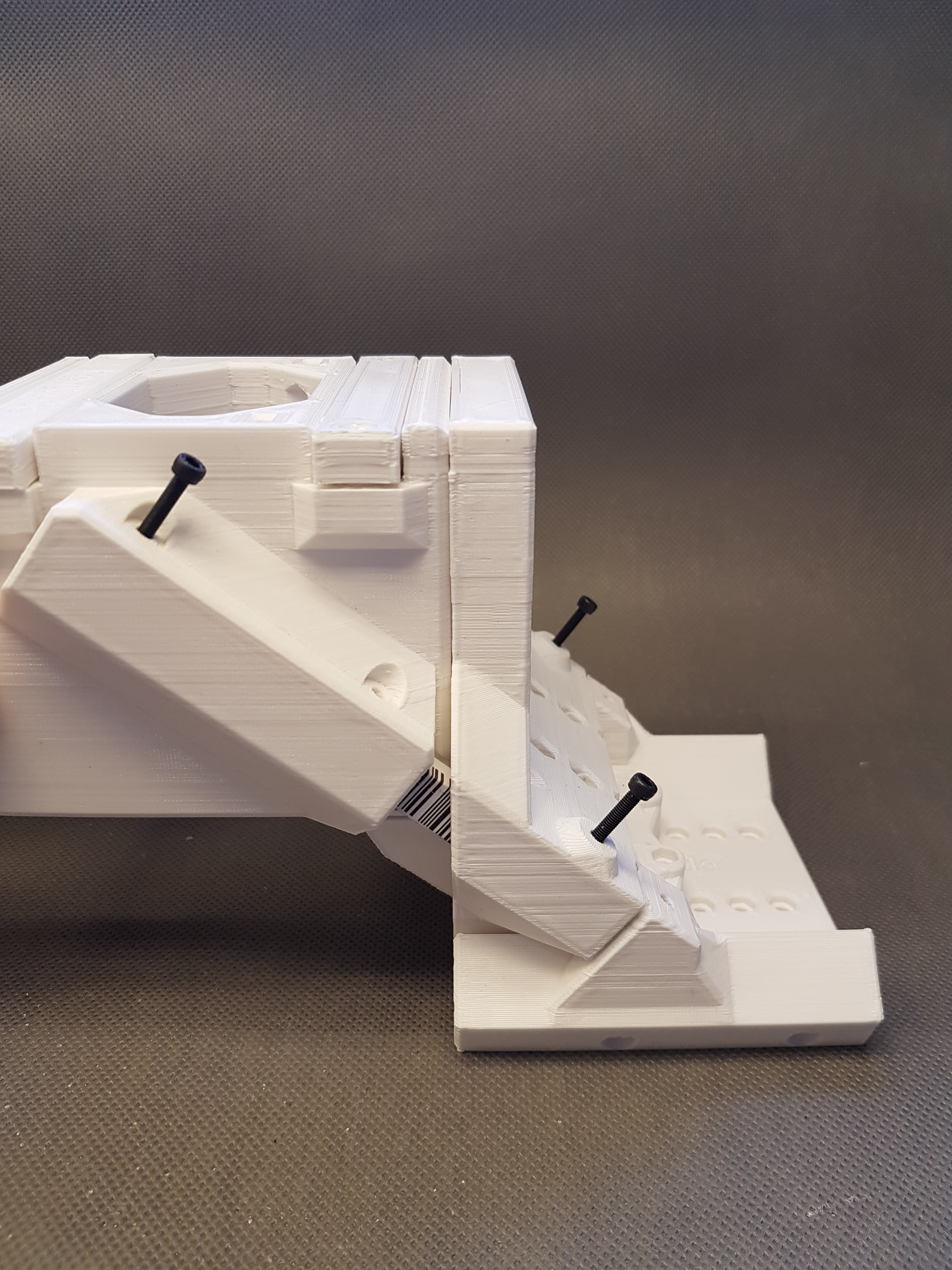

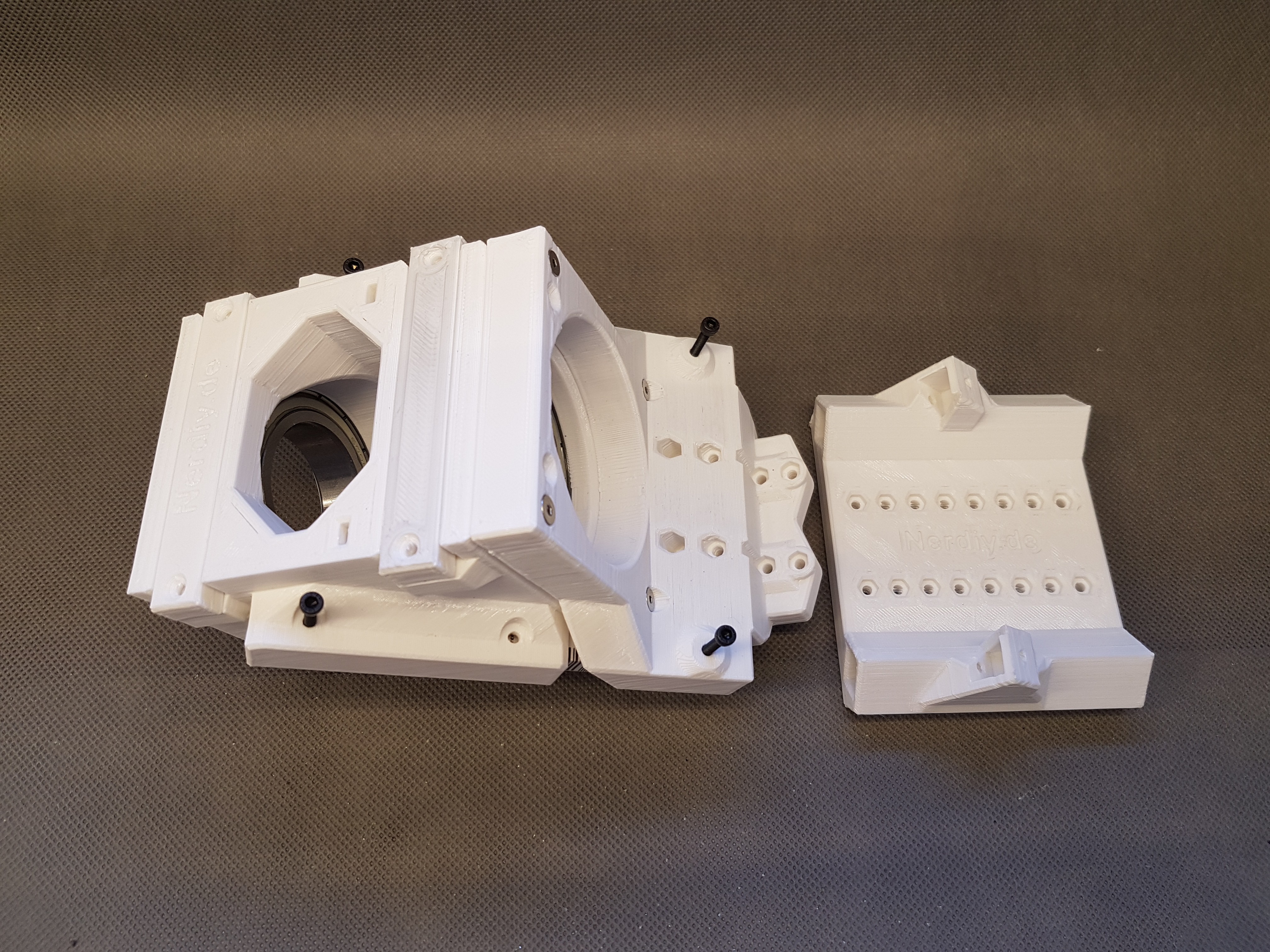

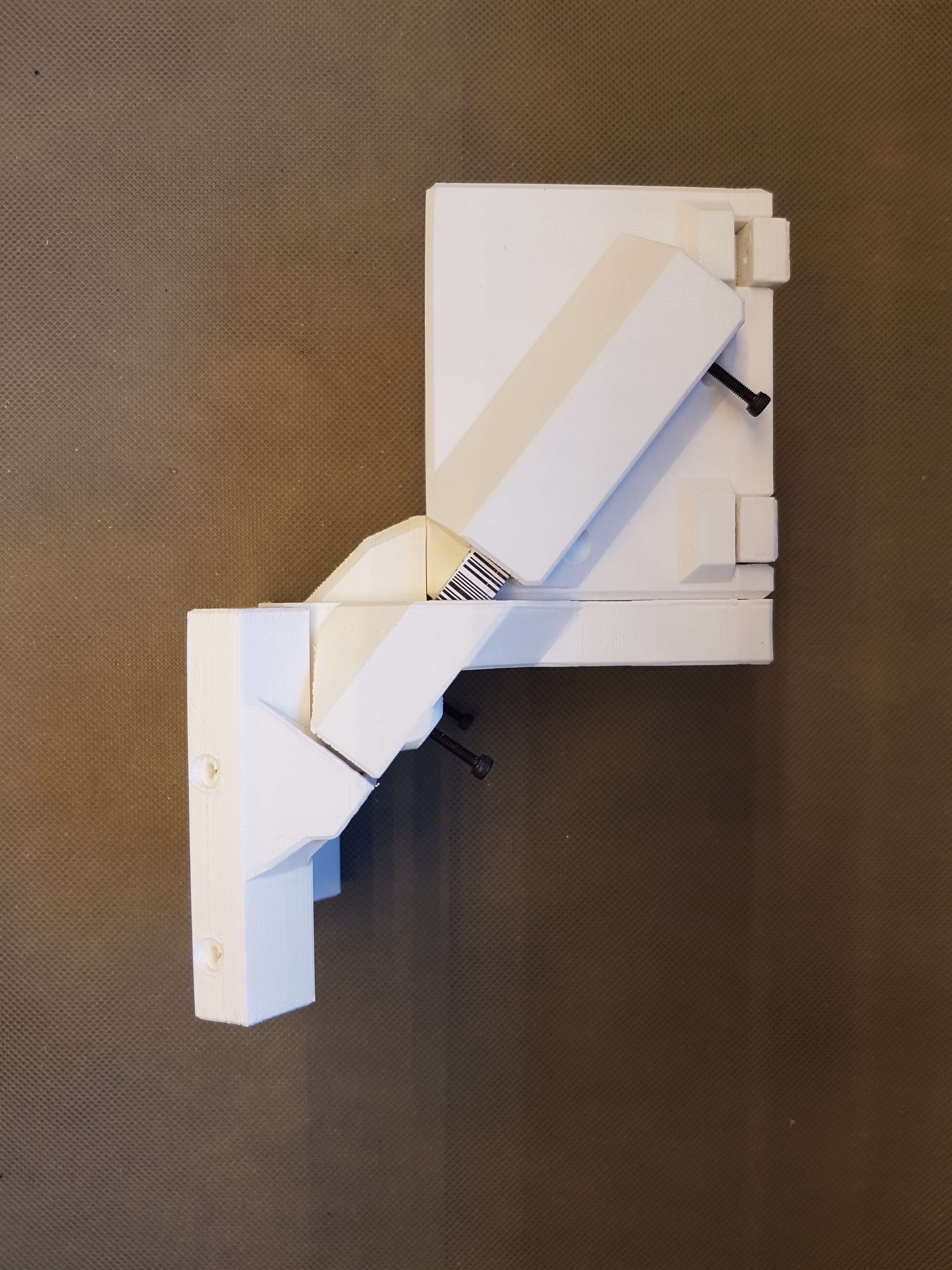

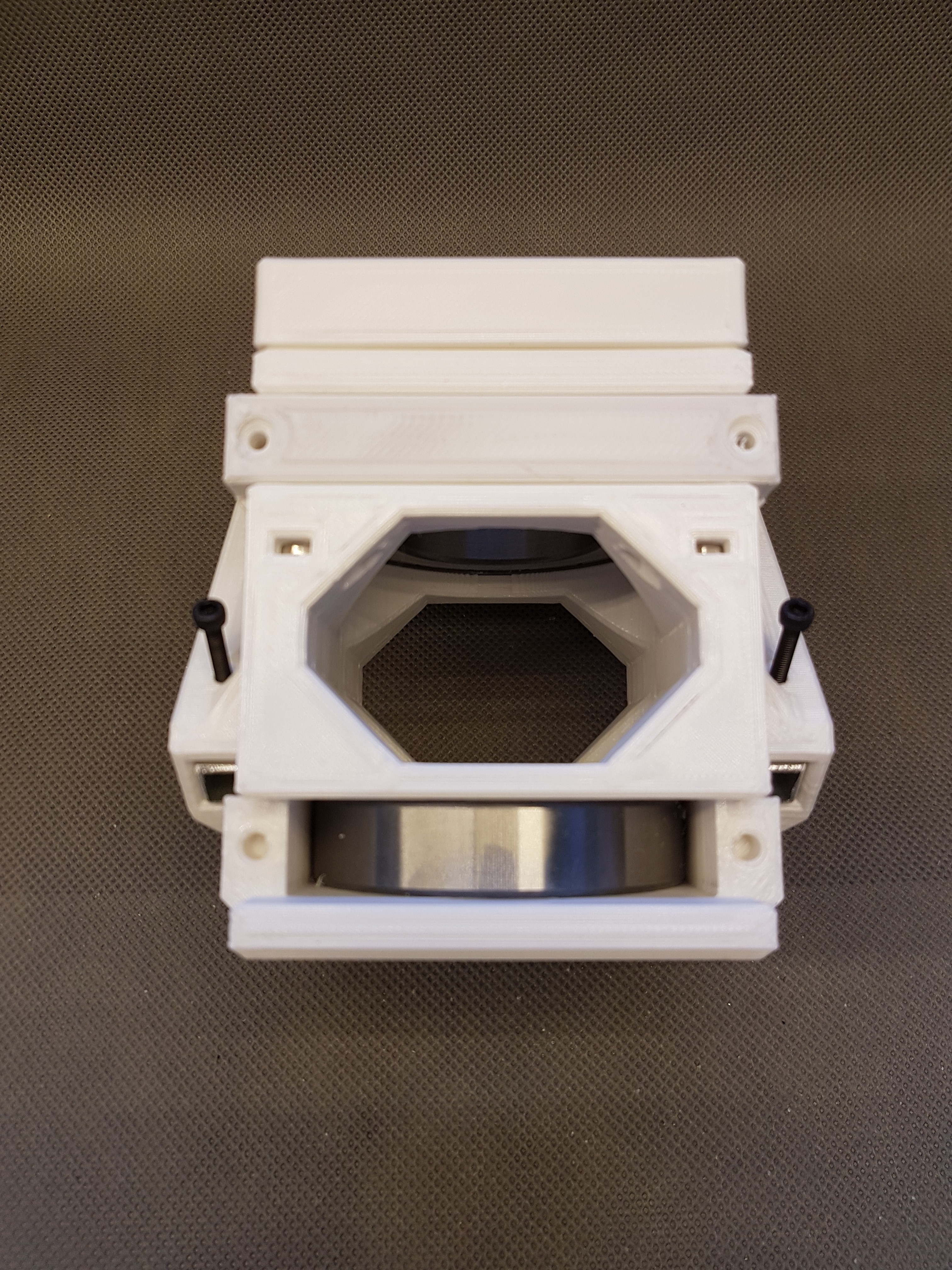

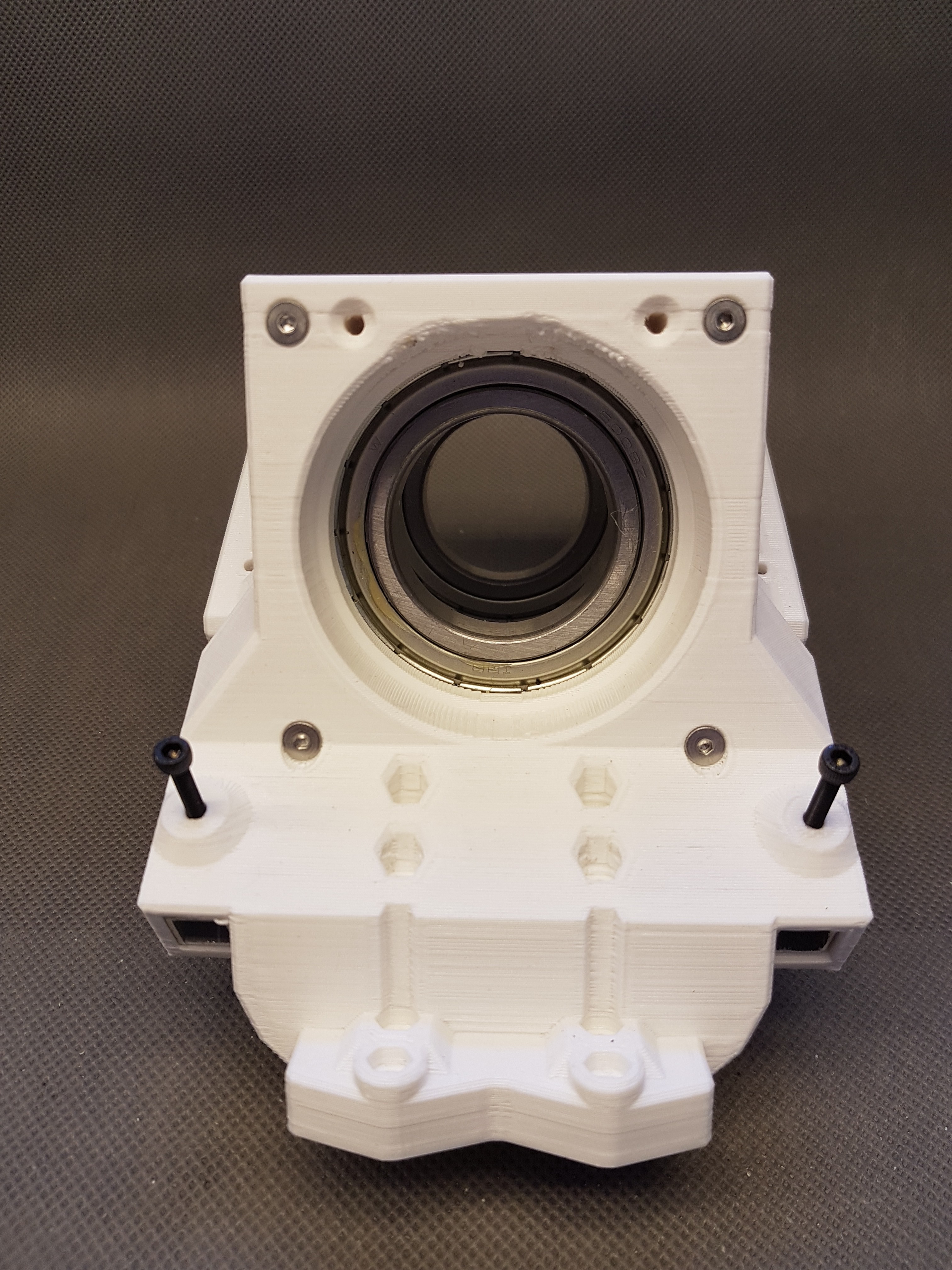

The new design of the main shaft bracket actually consists of two parts. (this is also a relief compared to the six parts in the previous design). In addition to the screws, these two parts are connected to each other by two aluminum profiles on the side of the bracket. In addition, these profiles extend into the holder on the base of WinDIY. There, this can be connected again with a long screw with the aluminum profile in the base.

The pictures below show the mount from different sides. To give you a better orientation here a picture of the mounted main shaft mount in WinDIY: (Note: The improved mount for the alumnium profile in the base of WinDIY is missing on the picture)

Fabian

Fabian

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.