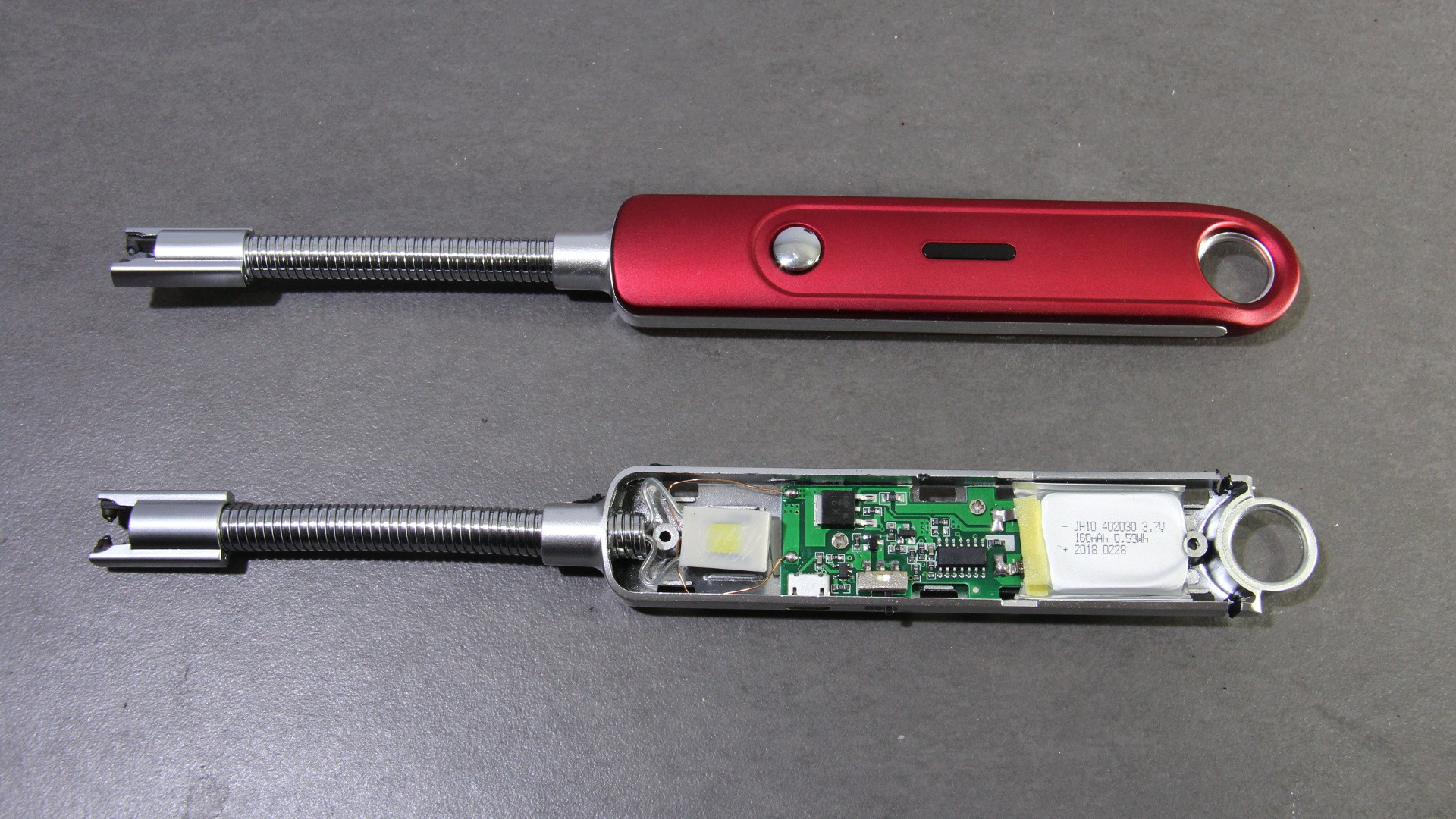

My interest in 2D printing has been reignited by Theo Deutinger, an Artist looking for an extremely slow, but continuously working printer (see Hackaday post for details). Using an old commercial print head will work for this purpose, but part of the deal with the artist is to look for a more DIY style printing technique. One idea is to build an ink jet nozzle from scratch. To get a suitable print resolution, you need a tiny, tiny nozzle. Electrical discharge machining (EDM) is a way to engrave tiny structures or to "drill" tiny holes. My DIY approach is to do something like that with a plasma lighter:

3 of them arrived today and I did a couple of quick experiments to see if "drilling" holes works in general:

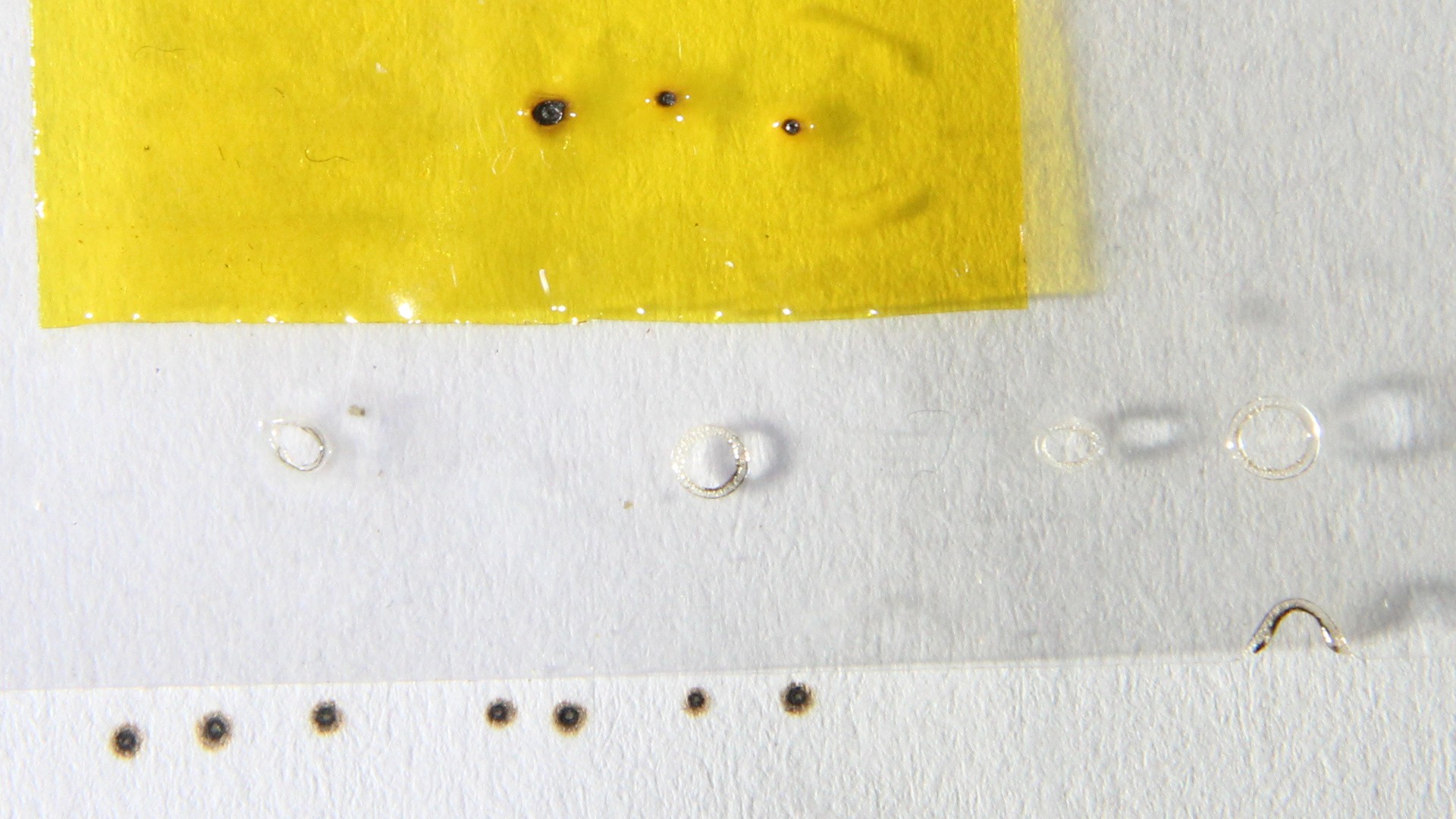

First results show that drilling holes through Kapton tape (top) works fine and you get holes of approximately 0.5mm even when firing the high voltage circuit manually through the push button and holding the tape in the other hand. In thicker plastics (overhead projector film) the results are 2mm holes. Next step is to connect the high voltage circuit to an Arduino in order to shoot well defined pulses of plasma on various materials to see what this technique is capable of. Also needed is a simple mechanics to get a well defined air gap, different electrode geometries, air cooling etcetera, etcetera. Lots of interesting experiments ahead to get tiny holes!

The bottom row shows what happens to paper when being between the electrodes. Paper is no suitable material for an inkjet nozzle, but what about a plasma printer? I am curious what dot size and print speed I can get while reducing the "fire time". It will be a thermal printer with no need for special thermal paper.

Norbert Heinz

Norbert Heinz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.