Why did we choose this exact idea?

Delta Robot is a really challenging machine to make as not only its construction has to be sturdy and give a lot of room to operate, but also we had to come up with complicated software for translating movement on 3 vertical sliders to XYZ space. These hurdles test our knowledge and creativity giving us more satisfaction out of working machine, but also lots of knowledge.

What is the purpose of such a machine?

Delta Robots are really flexible devices, because of their great manipulatory capabilites they can move nearly everything with a great accuracy in a 3D space, from simple drawing, through moving objects to 3D printing. As our robot has big dimensions its limits are also higher and 3rd party stepper Motors give accuracy and power needed for lifting even weighty objects.

Why did we base our machine on LEGO?

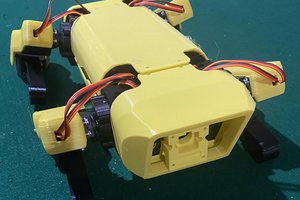

There are multiple positive and negative qualities to using Lego bricks as a main building material, as from the conception of the idea we were sure that we wanted to make our machine in real life, not only as a computer simulation one of the most important factors was availabillity. As most of our team members have a huge Lego models collection it seemed like a good choice. Plastic bricks aren't as sturdy as metal or wood elements, but they are light and most importantly they don't have to be constantly connected, which means that we can replace even most important elements on the go in a few seconds. As we started our project from physical build it was very important for our progress. Solid construction would be sturdier but also even small corrections would require hours, maybe even days of work, complicated machines and much higher expenses. As we didn't have any of them, working with nearly only our own hands was really helpful.

What is powering Delta Robot?

One of only few pieces in our project which aren't made of Legos are 3 stepper motors and Arduino-like board. We decided to go with them over regular Mindstorms components as first offer much higher power and reliability connected with smaller footprint and second gives us freedom when it comes to programming without unnecessary restrictions. We went with cpp as our programming language as it has advanced capabilites and we are familiar with it.

How we made this project come alive?

We tried to comply with social distancing practices due to pandemic, so all work that could be done online was indeed finished that way, but we also had to meet in person few times as making physical model required hand to hand cooperation. Programms like Fusion and Discord for talking helped us as a team. We could talk about future of our project in real time and share with team mates our progress.

What did we learn from this experience?

Most obvious things which come to mind are technical skills like better understanding of 3D modeling software, more mechanical know-how and real life machnie programming knowledge, but maybe even more important skills are of purely social aspect. We learned how to work better as a team, divide tasks between people which will do them best, planning our progress and evaluating in which fields we can improve.

A video showing simple movement and endstop functionality:

A video from a second test of a Lego Delta Robot. We fixed a pen refill to the manipulator to be able to plot something and see how precise the robot really is. The results were ok, as you can see in the video, even thought the pen refill was a little wobbly.

There certainly still is room for improvement and we will be updating the project in the near future.

LEGO Linear Delta Robot

LEGO Linear Delta Robot

Shifty

Shifty

Peter Buckley

Peter Buckley

Victor Barahona

Victor Barahona

Andrew Benson

Andrew Benson