The second round of performance testing with this device shows promising results. The main change to the system since the last round of tests is that the built-in 65 degC thermostat has been removed from the silicone pad heaters. The thermostat was previously limiting the max temperature measured by the thermistors at the hot plates to 48 degC. During this round of testing, the max temperature measured by the thermistors at the hot plate was 110 degC.

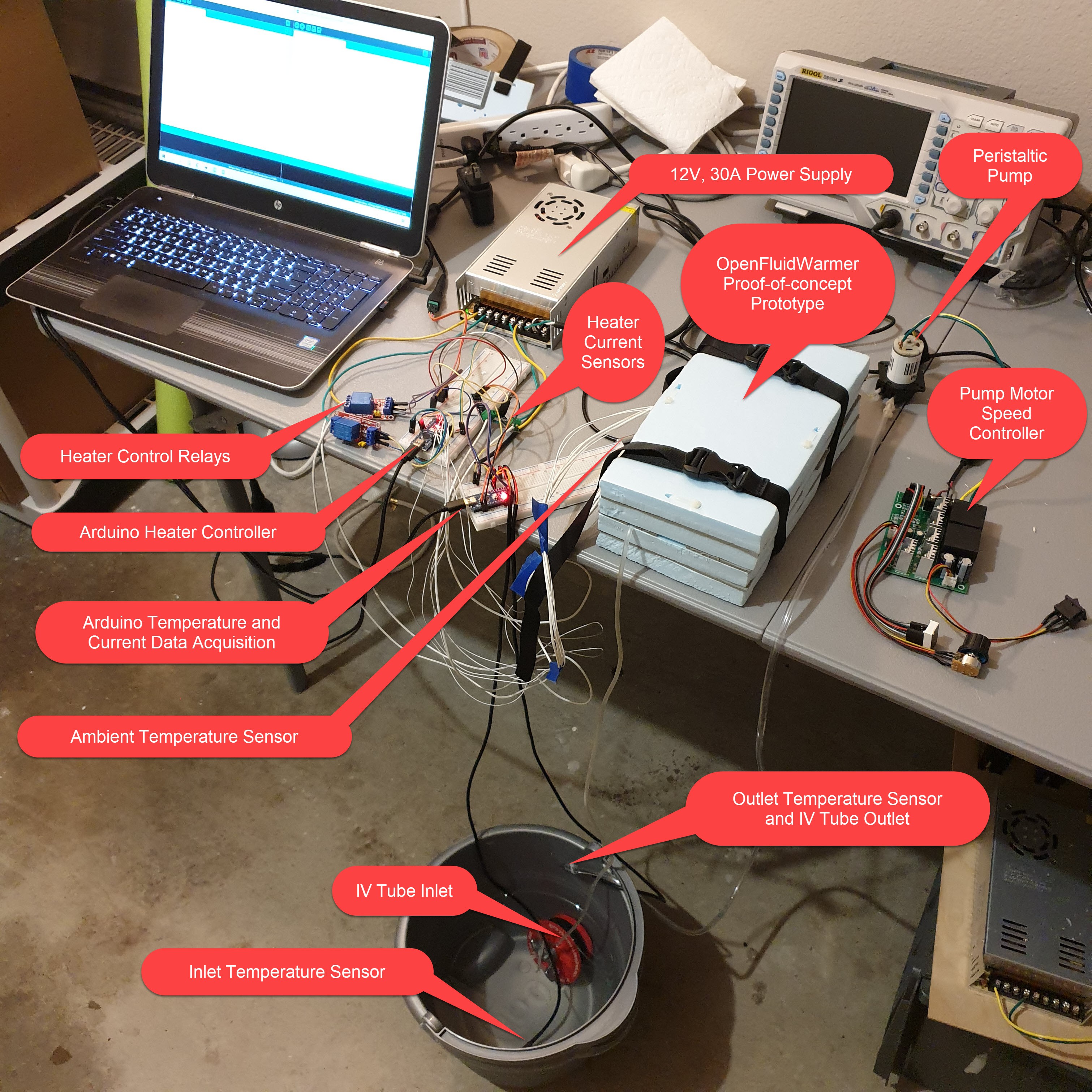

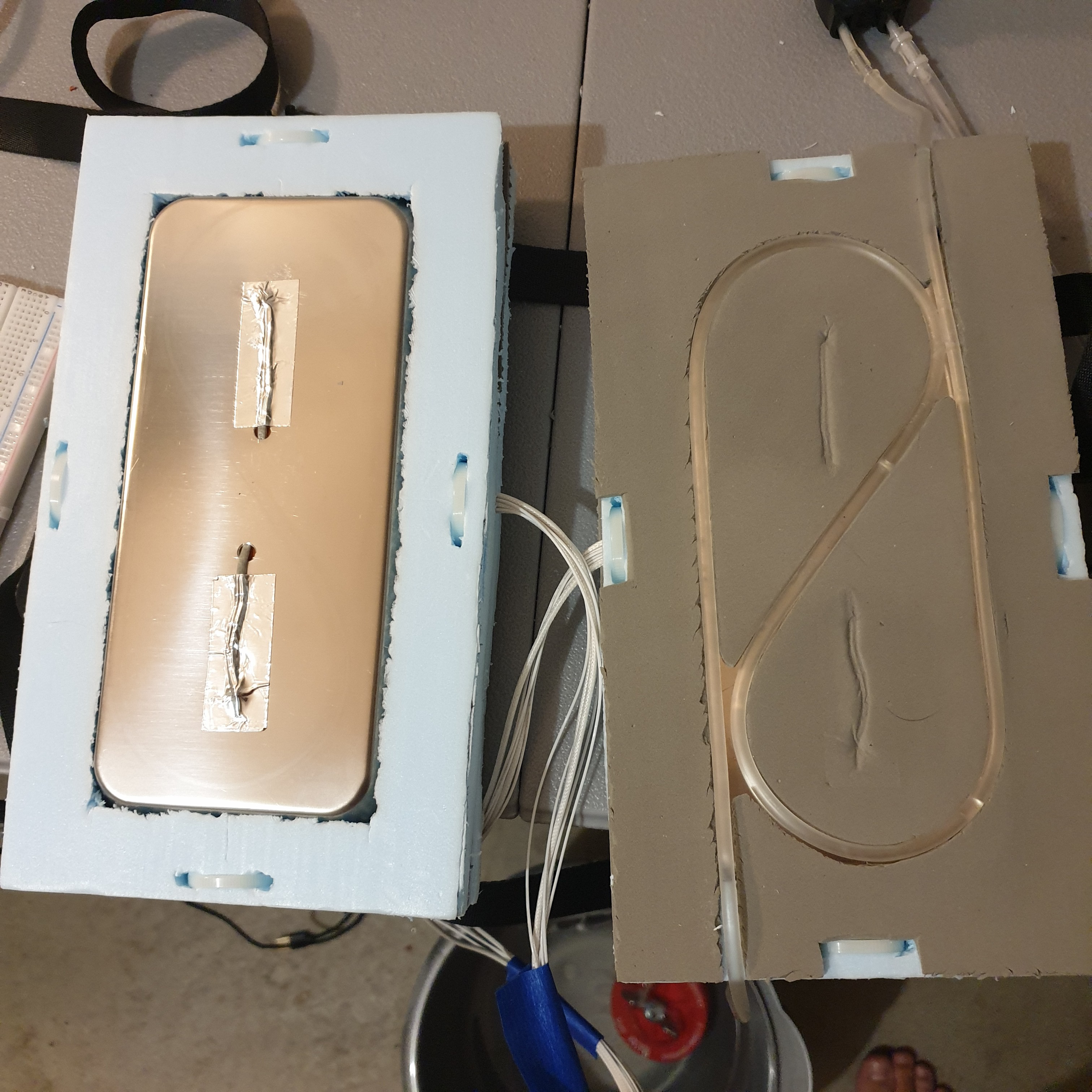

More background on the thermistor locations and length of IV tubing in contact with the hot plates is needed in order to give full context to the results. Two thermistors at located near the top and bottom of each hot plate and on the same side of the plate as the IV tubing. The thermistors are attached to stainless steel tray of the hot plate using foil tape tape. In the image below you can see them on the left hot plate. For the right hot plate, the thermistors are underneath the foam at similar locations. Each hot plate heater is controlled independently based on the average reading of the two thermistors. The length of tubing in contact with the hot plates is 660 mm (26 in).

The first test involved determining what hot plate temperature set point and flow rate was required to heat room temperature water to 38 degC. I eventually had to turn pump speed down to 50% in order to get a significant fluid temperature rise with a heater-off set point less than 90 degC.

Test parameters and results of the first test:

- inlet temperature, 27.5 degC

- outlet temperature, 38.0 degC

- total fluid temperature rise, 10.5 degC

- pump speed, 50%

- fluid flow rate, approximately 32.5 mL/min

- heater-off set point, 88 degC

- heater-on set point, 86.5 degC

- max observed temperature, 92 degC

The second test involved determining what hot plate temperature set point was required to heat ice cold water to 38 degC. It was able to achieve a outlet temperature of 27.5 degC at a heater set point of 105 degC. I wasn't confident how much higher I could push the heater before degradation to the polystyrene insulation foam so I stopped at the 105 degC set point. Inspection after this test showed no damage to the polystyrene so I plan to push the set point higher on the next round of testing.

Test parameters and results of the second test:

- inlet temperature, 4.5 degC

- outlet temperature, 27.5 degC

- total fluid temperature rise, 23 degC

- pump speed, 50%

- fluid flow rate, approximately 32.5 mL/min

- heater-off set point, 105 degC

- heater-on set point, 103.5 degC

- max observed temperature, 110 degC

92 degC and 110 degC max observed temperatures during the two tests is far above when hemolysis can begin to occur at 42 degC. Until I have the capabilities to prove that hemolysis does not occur at the max temperatures, it is recommended that the device not be used with red blood cell and other blood products damaged by temperatures above 42 degC. This relaxation in requirements is needed to maintain the strategy of heating the fluid through standard PVC IV tubing (i.e. not requiring a custom/expensive sterile in-line high heat transfer module) and using up minimal length of IV line through the device. A rethinking of the OpenFluidWarmer may be needed to achieve the original product requirements.

The next round of testing will identify what heater temperature set point is required to achieve 38 degC outlet temperature with a 4 degC inlet temperature.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.