Recently I wanted to start designing electronic circuits and make prototype PCBs at home as a hobby.

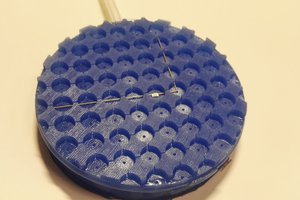

I started gathering all the necessary tools and techniques including things required for layout transfer, etching, drilling etc. Soon I realized that I will need a drill press for drilling holes inPCBs. I looked up options to buy, most of the decent ones were >$30 and bulky. Now I live in a small 2BHK apartment, of which I have turned 1 room into my lab and an another bulky addition to it would have required some good reasoning. 3D options were rare and required a lot of metal parts, not easy to find everywhere.

Putting things in perspective and defining use case: Neither am I a mechanical guy nor do I have any time or intent of specializing or drilling PCBs on regular basis, for professional PCBs I would just go to one of many PCB houses, as its just not worth my time. Hence this project, with the sole purpose of getting that first prototype/proof of concept board as soon as possible before wasting money and copper in getting them professionally made. The purpose of this project is not to be a potential candidate for replacing existing super complex, lightening fast and precise drilling techniques, but is to share, a super low cost way of getting something done with good enough precision, with the maker community, in a hope that it can be useful to someone with same use case.

This is a drill press for holding rotary tool flex shaft attachment. It is a cheap and easy to make drill assist that doesn't require a lot of tools, nuts and bolts and other metal parts and is quite precise. The flex shaft holder is detachable and If needed I can make a mod to hold the rotary tool instead.

Ruchir Chauhan

Ruchir Chauhan

jens.andree

jens.andree

Inne

Inne

Gary

Gary

Carl Giles

Carl Giles

Impressively hacky. Nice job!