Greetings from India !

As we are in the stage of design and engineering, there's also a lot of research and exploration happening in all areas: labeling, app development, and user-research.

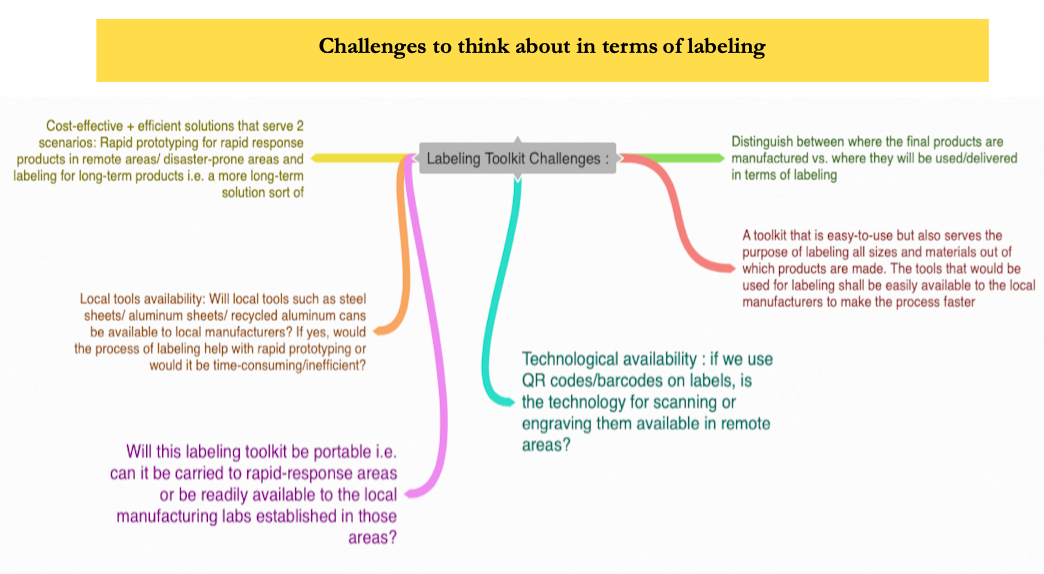

So far, we had tied prototyping a labeling solution using local tools that are extremely cost-effective, but now we want to think from Field Ready's material availability perspective. That being said, we are brainstorming a few challenges that can be encountered in terms of labeling a Field Ready product. I am also researching on the tools used in the maker spaces set up by Field Ready: 3D printers, workshop tools, laser cutters, CNC machine, etc. Below is the flowchart of challenges we need to consider while designing a robust labeling solution:

Along with this, some of our interviews with Field Ready members made us think about a few things:

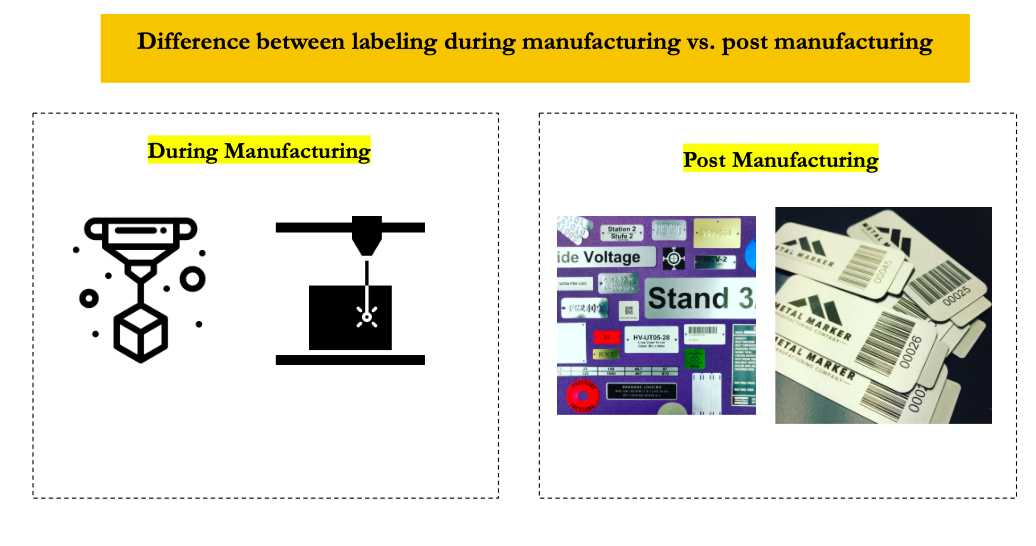

- Distinguishing between labeling while manufacturing products vs. post manufacture/delivering products to the end-users

- Different places having different access to electricity, internet or technology - but most of them do get electricity/internet for a few hours if not for the whole day.

- Currently, they use 3D printers, laser cutter, spray paint or simply a Field Ready logo stamp to label their products. Although, the product specifications are mentioned in the user manual along with Field Ready's contact information, it is not mentioned on the label. Our goal is to include that information on the label itself so that the user can immediately know how to contact Field Ready. And in case we have QR code/barcode on the label, the user can simply scan it and then report any defect or repair needed, or even give product feedback.

- Some Field Ready members prefer labeling while manufacturing whereas some prefer post manufacturing . And of course, labeling would depend on the product's size/material along with the fact that which scenario is it going to be used for: rapid response or long-term

So we plan to present a few options for labeling so that Field Ready members can test them for both these scenarios and then we can make a call as to what 2 methods would best serve the purpose.

Below is the distinguishing of labeling during vs. after manufacturing:

During manufacturing, Field Ready members can use the same tools they use for designing the product whereas after manufacturing, they can use local tools in order to produce a label for the products.

In our case, as you saw in the previous log, we are experimenting with aluminum sheet and how it can be engraved/embossed using local tools . Another thing e are thinking about is how to engrave a QR code on a metal sheet !

In the coming week, you will see more designs and methods we come up with !!

Stay tuned and please reach out to us or comment here in case you have any suggestions or ideas for this ! We would love to hear you out

- Field Ready Dream Team (Meesha, Tom, Antonio)

guptam

guptam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.