The schematic is very simple, the Si7020 use i2c protocol so it must be connected to pin 3 and 5 on RPi, the fan must be connected to pin 2 or 4 and all other component can be assign at different pins. Currently I use these pins because for me it was the simplest way to design the traces for the pcb.

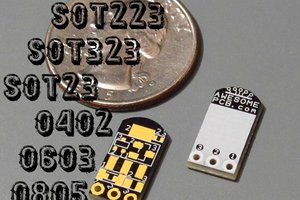

It is important to say that when I add component(or make trace) in the pcb design I always make this component pads at least 0.6mm. For example if the pad is with size 0.6x0.4mm I make it 0.6x0.6 and this is because my CNC is unable to make it smaller without cutting too much.

For pcb milling I use 30˚ angle bit with 0.1mm tip.

FlatCamp setup

For traces cutout

- Tool Diameter: 0.13 Type V.

- The "Cut Z" should be -0.06mm.

- Enable Multi-Depth with value: 0.03

- Travel Z: 1.2

- Spindle speed: 8000(this is max for my DC motor)

For holes drill and board cutout

- Cut Z: -1.501 *I use 1.5mm F4 PCB so this value should be changed according to your pcb thickness.

- Travel Z: 1.2

- Spindle speed: 8000(this is max for my DC motor)

I left all other settings unchanged:

bCNC setup

Before start milling I run autolevel and I aways set X-Y steps for probing to be maximum 3mm.

Boris Shabanov

Boris Shabanov

Jithin Sanal

Jithin Sanal

DIY GUY Chris

DIY GUY Chris

Simon

Simon

youkito1991

youkito1991