Accelerometer Contact Pickup

A simple/cheap exploration into sensing audio outputs from existing instruments.

A simple/cheap exploration into sensing audio outputs from existing instruments.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

|

Waveform Audio File Format (WAV) - 1.75 MB - 07/30/2020 at 01:32 |

|

|

|

Waveform Audio File Format (WAV) - 2.26 MB - 07/30/2020 at 01:32 |

|

|

Rev 1A.zipRev 1A Design Filesx-zip-compressed - 3.81 MB - 07/29/2020 at 03:54 |

|

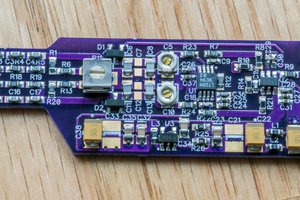

After finishing the layout for the schematic in the previous log, I ordered a few boards from OSHpark as well as a stencil from OSHstencil.

I cheaped out and went for a polymide stencil. This was a terrible decision since it's so floppy and a stainless steel one is only $5 more.

To assemble the board, I went ahead and found some old PCBs from college to lock my target PCB in place with tape. After placing the stencil on top and also taping it down I squirted out some low-temp-reflow solder paste and got to work with the spreader.

The results are... rather poor. There are quite a few pads bridged together, particularly at the QFN footprint & some of the sot23-5 footprints. I believe this happened because a few reasons: I used a floppy stencil. The jig-of-boards wasn't on a very flat surface and thus allowed for some wiggle of the target board. Lastly, I was greedy with my solder paste and only applied very small amounts in localized areas which meant I had to do several spreading passes to get full coverage. Applying a large amount of excess paste to allow for a single spreading action to get full coverage is a much better technique. In any case, these problem areas were pretty easy to fix with a pair of tweezers.

After then placing all of the parts, I reflowed the board in a second-hand toaster oven. Apparently you don't need to follow the exactly specified reflow temperature vs time curve to get decent results. Instead, you can just monitor the board's temperature with a thermocouple and just turn off the oven after reaching the peak temperature specified in the reflow curve.

The bake went pretty well... except for that accelerometer! You can see that it's rotated about 30 degrees and that the QFN pads don't align! To fix this, I used a hot air gun to reflow that whole corner of the board and fix. A nicer hot-air gun specifically for doing hot-air reworks, like the ones that Hako makes, would have been much nicer to use. I'm surprised I didn't end up sending all of the nearby passives flying, but this worked out pretty well anyway.

The astute will notice that, in my final assembly picture above, the TLV9001 has mysteriously grown 6th lead. After much head scratching and re-consulting of the datasheet, I realized that I had purchased the wrong part. I had designed for the "TLV9001 DBV" which I assumed was the only part that came in the sot23-5 package. In fact I had accidentally purchased the "TLV9001U DBV" because the right part is out of stock at Digikey. To solve this, I ordered a few "TLV9001S DBV"s since, besides the extra enable pin, it has the same pinout as what I needed for my design. Conveniently the enable pin is next to the positive rail pin, so keeping the part on by hand-soldering a bridge between the two pins was pretty easy. I also employed my favorite rework trick: stacking SMT passives on top of each other. I realized that my summing amplifier applies a |gain| of 1 to each channel. When all 3 channels are summed, there is a chance I can get a peak value of triple the peak of one signal and get a saturated output. So, stacking 3 10Ks in parallel on the feedback resistor pads was an easy way to bring the pass band |gain| down to (1/3) for each channel.

As expected, powering the device from the mic bias did not work. With battery power though, all components operate as expected. After mounting the board to the back of my uke with some electrical tape, I made a quick recording in Audacity.

This signal is pretty distorted because of saturation at the input of the audio codec. After adjusting the recording levels, I was able to record something that sounds a little better.

Unfortunately, there's quite a bit of noise, but I'm happy that it doesn't sound super awful. For now I want to play around with the jumper settings and analyze the differences between the waveforms of the three channels. Then, for a next design, I'd like to properly tackle the...

Read more »After creating a proof-of-concept with an ADXL337 from Sparkfun and some conditioning with a breadboard, which was super noisy, I went about putting together a schematic for a small PCB. I ended up choosing a FXLN8361Q from Freescale (NXP). Compared to the ADXL337, it does have marginally lower noise density. On Digikey, the price difference between the two is only a few cents.

I wanted to design something that would meet the following criteria:

- output to a 3.5mm audio cable

- be battery powered

- be mic-bias powered

- cheap

I wanted to output to a 3.5mm headphone jack so that I could plug the device into my PC and record some sounds as either a Line-In or Mic-In source. There is a pretty dizzying array of options for microphone pinouts with TRS or TRRS 3.5mm jacks. A fairly common 3-contact TRS pinout for microphones is [Left, Right, Gnd]. I ended up choosing a TRS pinout with a [mono-output, bias-in, gnd] mapping for simplicity's sake. I threw in a summing amplifier with some 1st order low-pass & high-pass filtering. This allows me to have an AC coupled output with some noise reduction and an output resistance of basically 0 Ohms. The FXLN8361's output impedance is roughly 10KOhm. By interposing some 3 pin 1.27mm headers between the accelerometer and the input of the summing amplifier, I can play around with turning on different combinations of the X, Y, and Z directions.

The second design criterion was pretty easy to satisfy. I chose a CR2032 as it's a relatively common button cell battery that has very good capacity compared to other button cells. Furthermore, its discharge curve reduces from 3V to about 2V when it is empty. In order to maximize battery life, I chose the positive power rail to be a linearly regulated 1.8V off of the battery voltage.

The third criterion was not very easy to meet. Most audio codec ICs can source a very small amount of power from reference voltages that are tied to the input signal lines of the mic-in/line-in connectors via pullup resistors. For example, the Qualcomm WCD9335 that sits in the Pixel 1 phone can source 5uA to 6mA for a mic load. The load regulation & accuracy is seemingly pretty terrible though and the datasheet claims that it can be anywhere between 1V and 2.85V. The current limiting pull-up resistor itself will also effectively degrade the load-regulation. The codec from Realtek that sits on the motherboard of my PC, an ALC887, apparently has an output reference voltage that can be configured for either 2.5V of 3.75V. But, the sourcable DC current isn't specified. Realtek's recommended audio jack schematic shows us what we can expect in terms of a size for these pull-up resistors:

In any case, the FXLN8361Q only consumes about 180uA of quiescent current when powered with 1.8V. The op-amp I chose for some basic filtering, the TLV9001, has a worst case rated quiescent current of 77uA. If the power supply components can all be kept fairly low power, and sufficiently large resistors are used for general pulldowns/pullups and filter components, then the core circuitry should consume < 500uA.

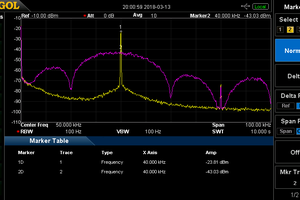

The required negative rail for the op-amp is a linearly regulated output of an inverting charge pump. The inverting charge pump is an apt choice here as it is much more efficient than other switching topologies (e.g. inverting buck) at these low power levels. A charge pump also requires many less external parts which is nice. Since the AC coupled version of the signal cannot be greater than (1/2) 1.8V, it's ok for the magnitude of the negative rail powering the op-amp to be a little smaller than -1.8V. Given restrictions on the drop-out voltage for the linear regulator, I chose the negative rail to sit nominally at -1.453V. The charge pump switches at well above the audible range (30KHz min, 50KHz nom) and the linear regulator following it has a PSRR of about -35dB at these frequencies, so I'm not too worried about switching noise impacting the audio quality. All in...

Read more »My journey for this project started about a year ago. I had picked up a ukulele as a new instrument to learn in my free time. I had a desire to do some kind novel project outside of work and decided I was going to find some new, unique way of recording the vibrations from a stringed instrument. If I could find some strange, non-traditional method, I might even be able to affect the dynamics of the string's vibrations to create a new sound. Transducers with highly non-linear responses, for example, would enable this.

This accelerometer project though, is a bit of a compromise and is effectively my third concept iteration on the target described above. Though I didn't realize it at the time of coming up with my first prototype of this iteration, I have since found that the idea is not original and has already been applied by several people. Most notably, I found that a few people at Analog Devices, who make several of these analog-output MEMS accelerometers, wrote a paper on the subject. Furthermore, this method is a very close cousin of contact piezo microphones that already exist on the market.

I want to talk briefly about the first two concepts because I do think they are interesting and I may want to revisit them someday.

Concept 1 : Optical Fiber Pickup

The idea behind this concept was to replace the strings with optical fiber and then feed them with spectrally narrow-ish-band (LED, not laser) light in CW mode. With notches then cut into the fiber somewhere between the bridge and the fretboard, I was hoping to be able to cause some of the light to exit TIR and transmit down towards the body of the ukulele. By then placing an array of 4 photo-diodes below the strings, I would have the option to either produce a poly-phonic output or a single analog output via a summing amplifier. If I could get the output beam to be sufficiently narrow/low-divergence, then string vibrations should create a proportional, variable irradiance incident upon the photodiode.

Some of the inherent limitations I ran into with this idea include:

- In the prototypes I made, I was unable to create the right type of notch that would cause enough of light to exit TIR in a controlled beam down towards the photodiodes.

- The notch making process I employed was very crude and purely experimental though. Maybe some real optical engineering and some iterative ray-tracing simulations could lead to an optimal notch shape that would allow enough out-coupling efficiency to exit to get a reasonable signal.

- In general, the available plastic optical fiber that I found is not rated for the string tensions required by the soprano ukulele. If the required frequency or required string length is reduced though, the required tension can decrease enough. The required tension increases with the square of the fundamental frequency and linearly with the length. Something like a bass guitar would be more apt for this.

Some other downsides include:

- Even the cheapest LED fiber-coupled transmitters I could find are both bulky and expensive.

- I was unable to figure out how to robustly constrain the transmitter end of the fiber mechanically. The aforementioned transmitter holds the fiber in place via a friction fit with a plastic lock nut. This was definitely not strong enough for the required string tensions.

- To prevent noise from the ambient light from destroying the signal or even saturating the sensor, optical filtering material would be needed to enclose the section of the bridge with the sensors. The most straightforward way would be to use some black material to block the entire spectrum, but a a cooler (and more expensive way) might be to use some kind of material that attenuates only the spectrum being transmitted through the fiber. For example, if a UV light source was used, then plexi-glass could be used since it acts as a longpass filter with a cutoff wavelength near the blue-light to UV-light transition zone.

Concept 2...

Read more »

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Jovan

Jovan

Ted Yapo

Ted Yapo

Bud Bennett

Bud Bennett