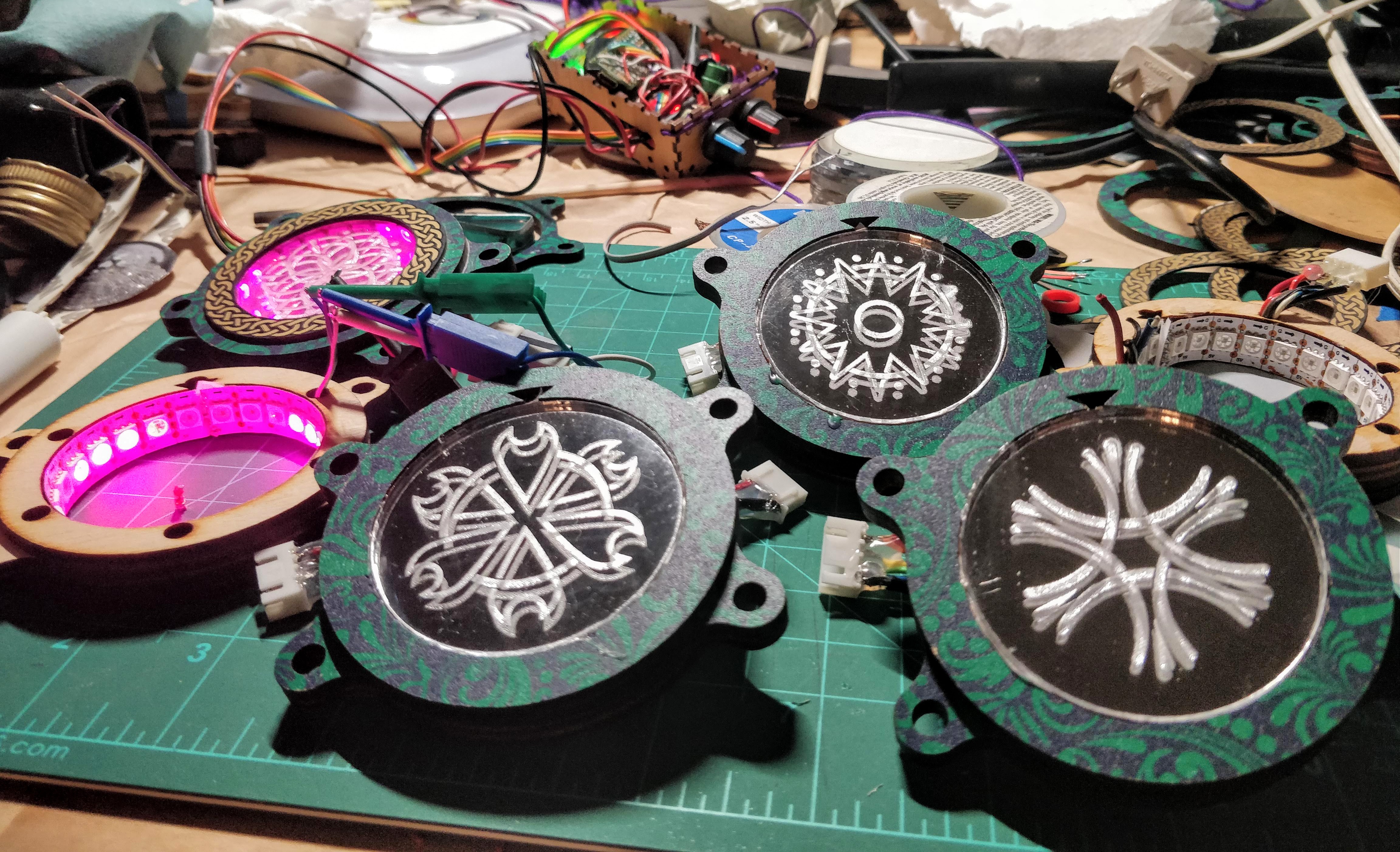

In the day, it's a bunch of mirrored discs with Burning Man's 10 Principles.

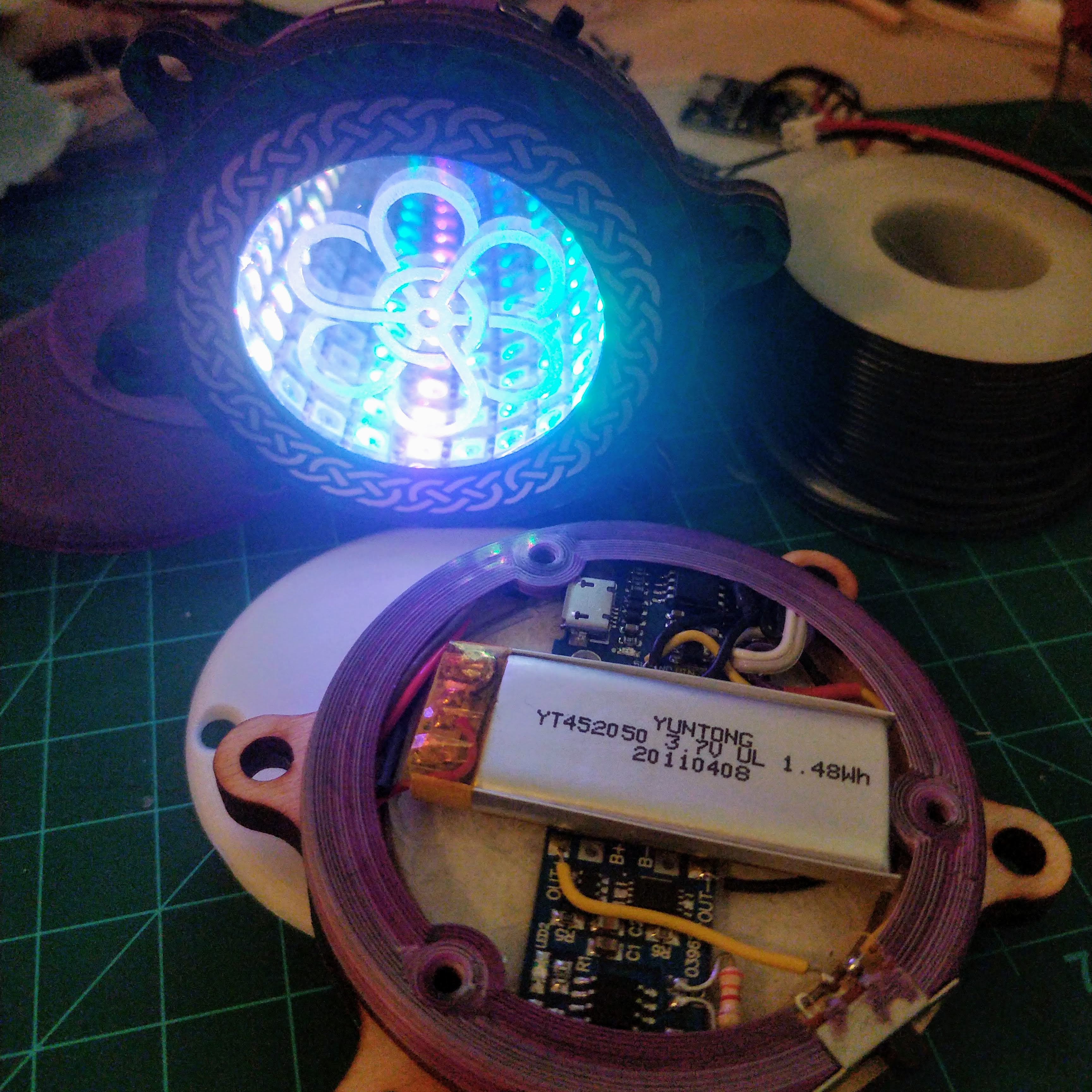

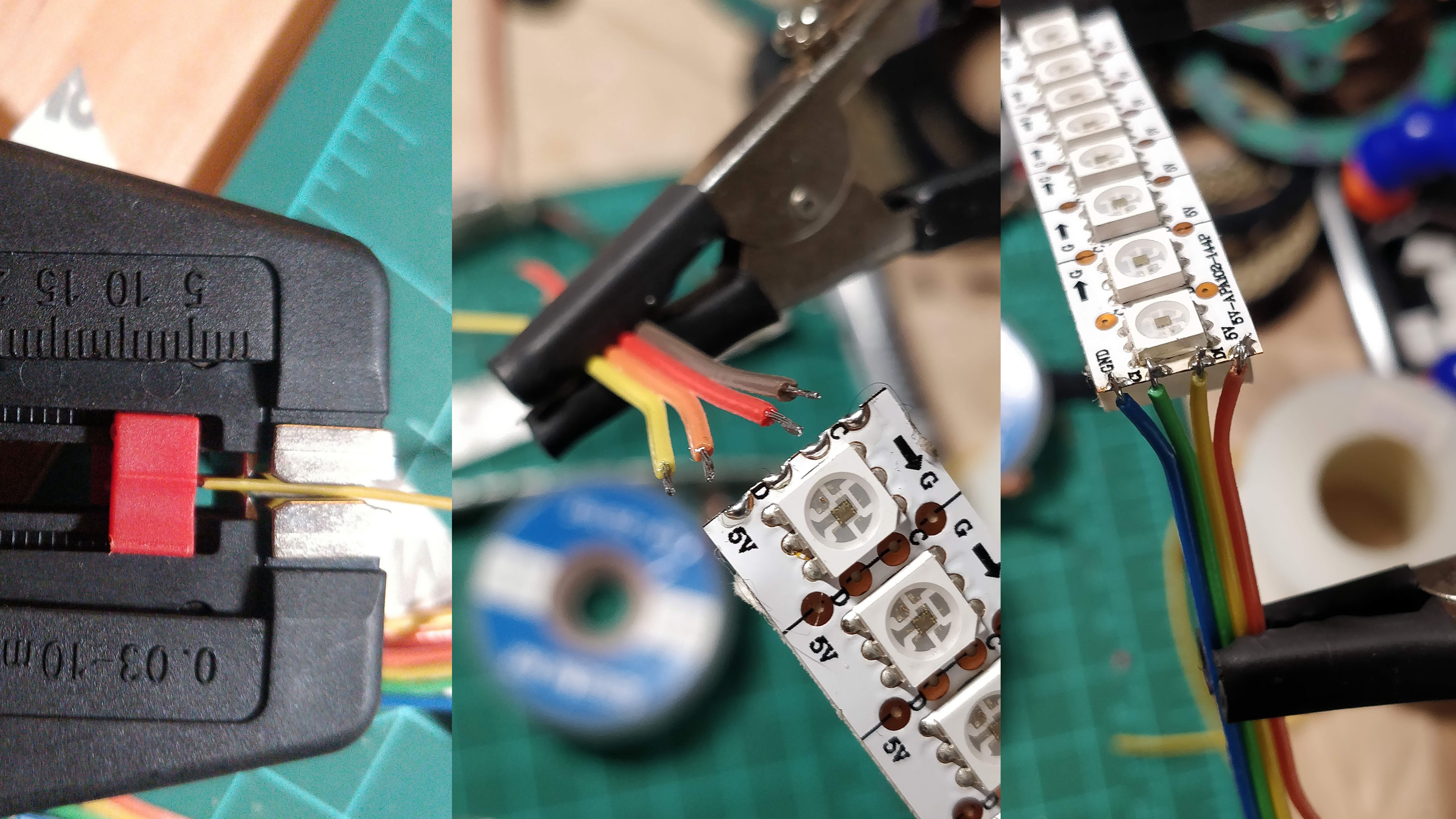

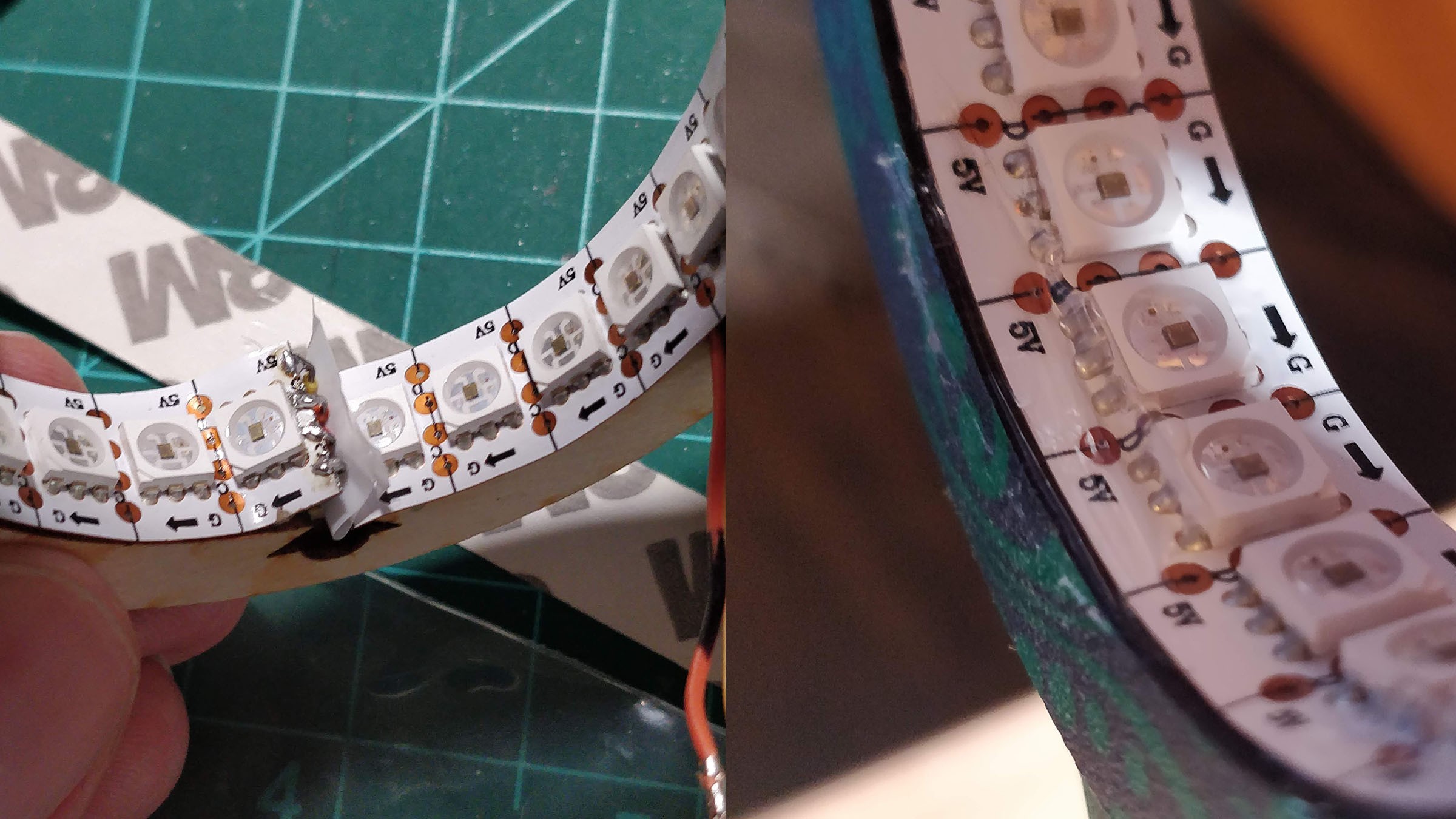

Unlike goggles I had made before, a belt has 360 degree visibility. The code incidentally is the same I used for my goggles, with just some #defines the the bits that are different. It has two controls: brightness and pattern-select. The mode can select specific patterns, or cycle between various patterns. It's driven by a Teensy LC, and powered by a 3S LiPo pack connected to a buck converter / BEC to drop it to 5v. 5Ah lasts a full night.

The only clip I have of it in use at BRC 2017:

I wonder if I might be even more interesting if had etched the symbols on the mirror side so they would glow more and be reflected themselves.

Ted

Ted

Angela Sheehan

Angela Sheehan

Padfoot

Padfoot

Peter Fröhlich

Peter Fröhlich

Tom Nardi

Tom Nardi