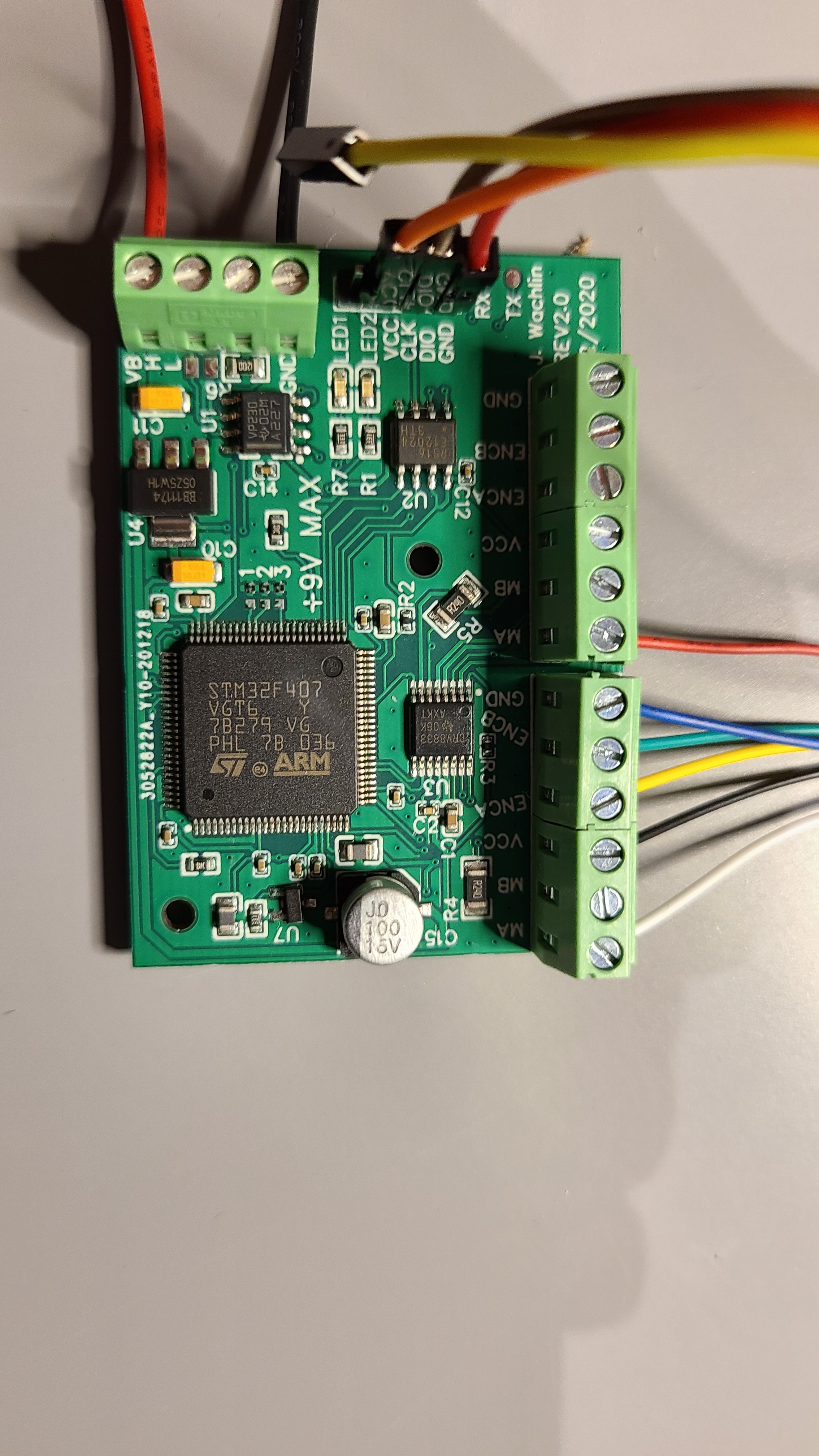

As discussed in the previous log, I developed a 2.0 version with a main goal of improved performance. I upgraded the microcontroller from a Cortex-M0 core to a Cortex-M4F alternative. While doing this, I also jumped from Microchip's SAM line of microcontrollers to the STM32 family. I am relatively new to STM32, but this project is a good learning experience.

The STM32CubeIDE makes it easy to set up all the peripherals and middleware such as FreeRTOS. Because the previous version was built on FreeRTOS, and most of the more complicated code was agnostic to hardware, porting the firmware over was fairly straightforward. So far, I have:

- System boots up and FreeRTOS is running

- Position control and motion primitives are working

Control Optimization

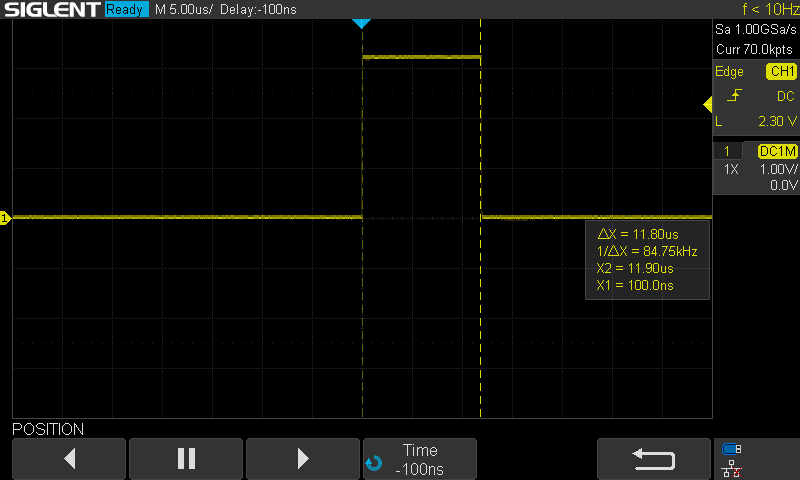

In previous analysis, the calculations for motion primitives to determine the next setpoint were separate from the low-level control loop calculations. This was done due to limitations with how slow the primitives calculations were. Originally, before optimizations the motion primitive calculation took 1.88ms and the control loop took 236us. By setting up pre-calculations and implementing the control loop with only integer math used, this was much improved. However, the pre-calculations were very memory limited, and it was still not very fast. This new microcontroller is much faster.

Now, with a floating point PID controller used for motor control, the control loop itself only takes about 11.8us!

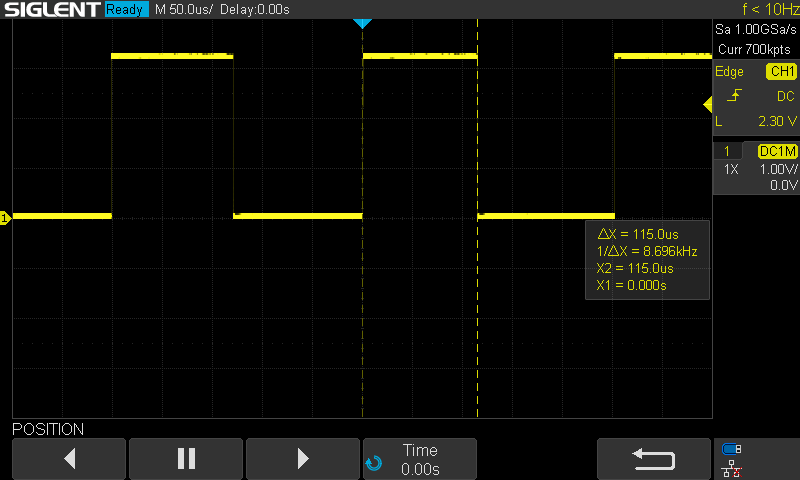

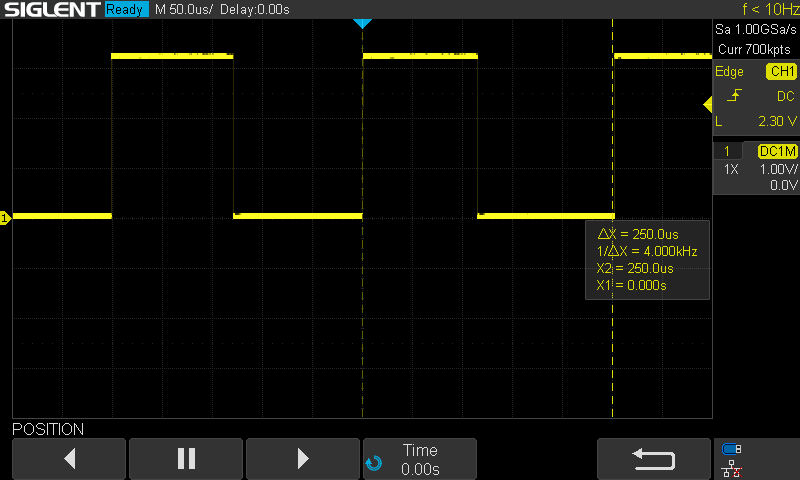

That is great, meaning we can set the controller to run much faster, get better current control, and smoother motion. I therefore updated the control rate to 4kHz (from 500Hz originally). I also set the controller to motion primitive mode, which calculates a Bezier curve, inverse kinematics of the leg, and PID control of both motors on each cycle. Without optimization, this requires 115us. This is about 18X faster than the previous version! We can also see here that the loop is running at 4kHz now.

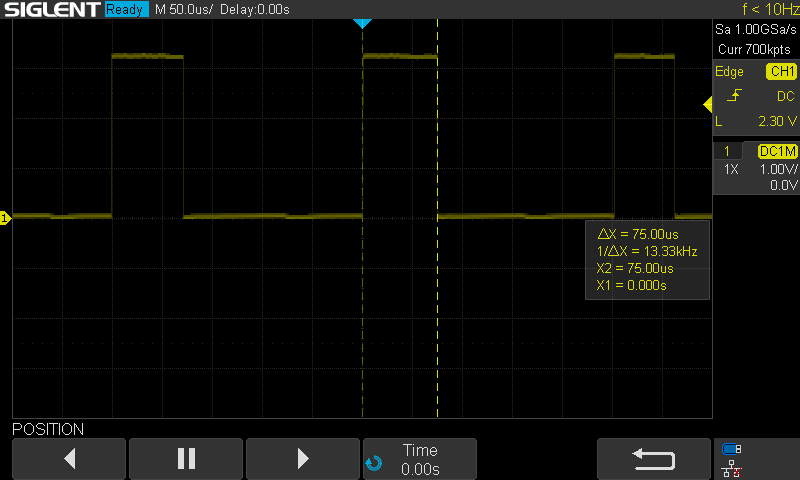

While this is probably good enough, I wanted to do a bit more optimization. The inverse kinematics use both arccos and arctan functions. I figure that these are likely slow, so set about to make faster lookup table versions. This is still a work in progress to improve its accuracy, but did speed up the calculations down to 75us total, now 28X faster than V1.0. While not measured, I couldn't tell the difference visually or audibly using the fast versions versus direct calculation.

Next Steps

- Set up CAN bus interface (RX and TX)

- Test multiple devices on a network

- Swap out current sense resistors

- My chosen values were too low, I forgot that the SAMD21 ADC has a PGA but the STM32 does not

- Test and tune current control

- Test and tune Virtual Model Controller

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.