Our BASF Ultrafuse rPET arrived! First tests are good: the results are similar as PET-G and it prints with the same settings. It's a bit stiffer though, but the difference is way smaller than between PET(-G) and PLA. BASF's rPET claims to have a flexural modulus of 2,15GPa, generic PET-G should be around 2,1GPa, and PLA around 3,5GPa. In scientific papers we can see that PET-G sometimes has a lower flexural modulus than specified, which would explain the difference in our tests.

The color seems to be a bit less bright than the official product photos. Certainly for small parts this is something to be aware of. Below is an example next to a red and a green PET-G part.

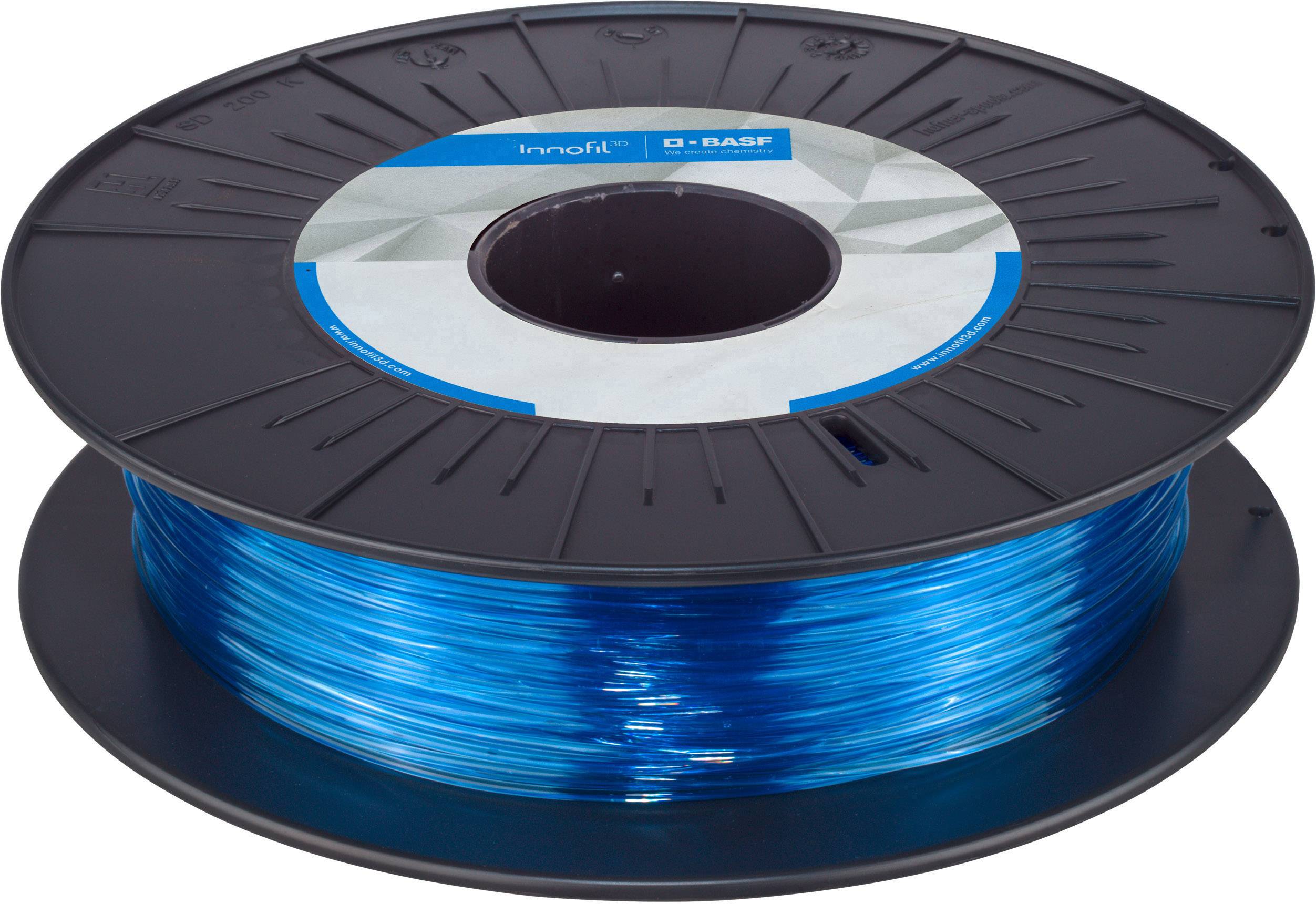

Original product picture from the BASF website:

(Please not that we are not affiliated with any of the brands mentioned)

(Please not that we are not affiliated with any of the brands mentioned)

Bram Peirs @ FW2W

Bram Peirs @ FW2W

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.