I started this project in 2016 when i been on first year of bachelor. More active work i stated from 2018. I developed own metal additive technology and i created experimental implementation of it. This experimental implementation may call as metal 3D printer. My own metal additive technology based on physics of induction heating and fused deposition of melted liquid metal (there is some analogy with plastic 3d printers). Welding wire is used as a consumable material (In experiments i have used aluminium alloys).

Welding wire has much more cheaper cost than an metal powder for SLS,EBM etc..

If use my technology then may give significant lower cost of all system due to my technology is not using laser modules, ovens for debinding, metal powder, etc which has relatively high cost.

I showed some photos which describes my current results of printing first lines (tracks) and dropjets from aluminium alloy. My target regime of printing - lines than dropjets. I have look that i was able to achieve lines without support between two points! - probably it is additional advantage.

Potentially, this technology allows to create printers with scalable work volume.

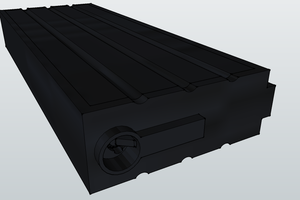

My metal 3D printer consist of several modules. An main module is print head. Each module i developed and created manually. I used analytical and numerical methods that to develop them. It is very complexity to find such solutions which may be optimal by all variables...

At first time, FASIE fund helped to me. But financial resources were limited within the program - to show the overall viability of the technology. Due to the lack of this resource ( btw i did more experiments than i planned) I have so far reduced the development activity on this project. And for the same reason i don't have fully functional 3d printer, but i have success to show the overall viability of the technology.

P/S 1: Dear friends, it is important for me to get helpful participation (Donate). My development activity on this project will depend on it!!! if you want to write feedback, please write in private messages.

P/S 1: Pay attention to the fact that this project while isn't open-source.

P/S 3: I understood that this description is abstract, in fact, my technology is much more complicated and takes a lot of time to describe it. By this reason description will be continued.

This project also was as my bachelor's diploma project, and i have defended it on excillent.

You can donate to the project.

Sergey R.

Sergey R.

sujoy2900

sujoy2900

roboteurs

roboteurs

Pavel Semenov

Pavel Semenov

TAIBHSE DESIGNS

TAIBHSE DESIGNS

Hah, I planned to make exactly this sometime. One suggestion that I've found - smaller diameter heating coil will get you better efficiency.