Been a little quiet here lately. Here's some pictures while I go find some words to go with them.

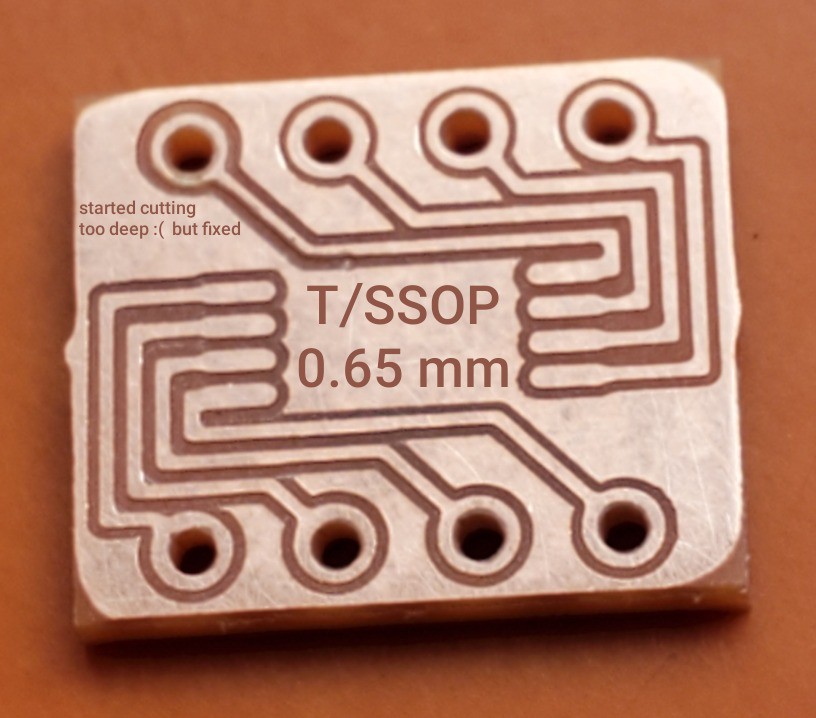

Words about runout & {autoleveling <- homing <- limit switches} vs {mechanical bed leveling <- Z probing non-conductive surface} & um, what else? (update: nix limit switches; I was wrong about why I thought autoleveling required homing requiring limit switches)

Previously about PCB milling:

- second & third tries

- first try didn't get a log entry

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

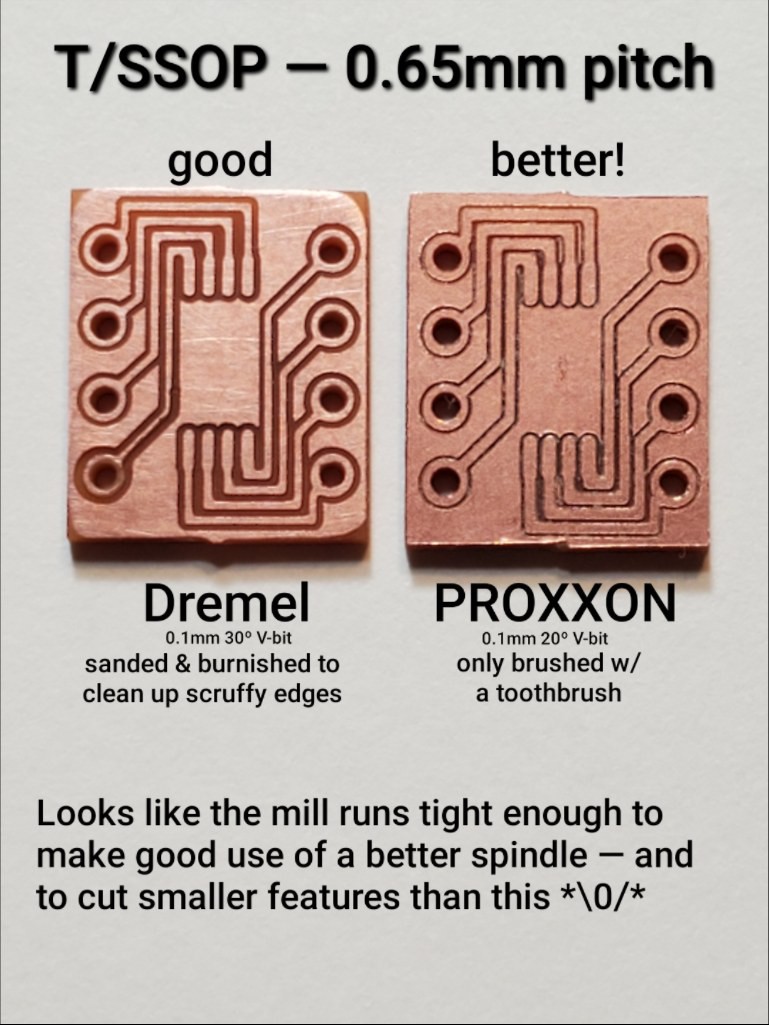

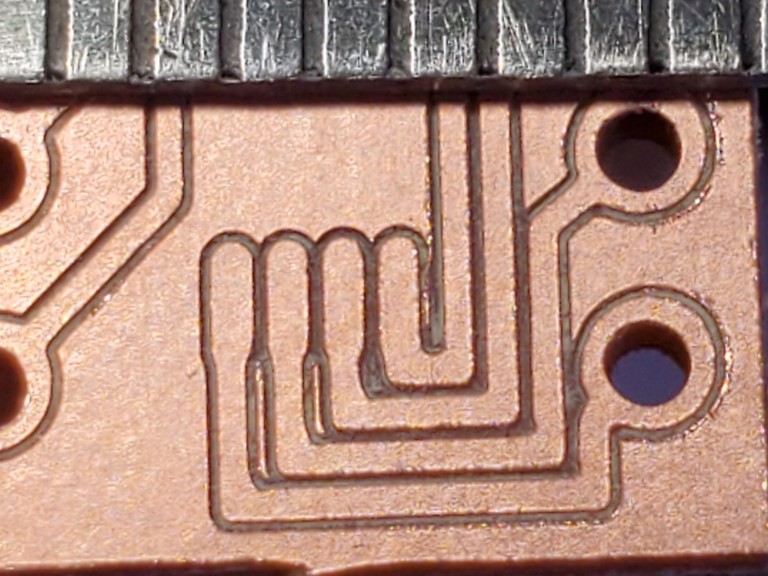

This does not surprise me :) I opened up my black&decker dremel-style tool once, and the spindle design is completely ridiculous. There's only one bearing on the actual shaft that holds the bit. The other end mounts to the motor shaft using a plastic ball joint. So it's intentionally designed to allow the bit to trace a conical path in order to simplify the construction, and before long the ball wears down and becomes loose in its socket as well, allowing the bit to pull to the side under load. Even the bottom-dollar Chinese CNC solution of a rigid shaft coupler with set screws to attach the bit directly to the motor shaft would be much more precise.

Are you sure? yes | no

Yeah. IME none of the Dremel-like tools match a real Dremel. Not that Dremel brand tools are all that great but I give them credit for being "good", with "straight enough" shafts & collet bores and "close enough" tolerances between shaft, collet & nut. Clones range from bad joke to almost-but-not-quite -- mainly in terms of very loose to almost but not quite as close tolerances between shaft, collet & nut. Sounds like your B&D is also designed to degrade itself from whatever it was new. :-/

The point of comparing Dremel & PROXXON was more for appreciation of the superlative tool than to dump on the Dremel - which did get the job done.

Dremel's downfall is crap collets. Getting the "good" result pictured required picking the one least eccentric collet out of a mostly-new Dremel brand retail pack of eccentric collets.

I haven't written much yet about the blue Wen dremeloid used for most of this project so far to keep it cheap. The main trick with that is wrapping the collet stems with tape to fill in the *very* loose fit into the shaft end. Then tweaking for acceptable runout. I don't think it was ever going to cut the SSOP footprint tho.

Are you sure? yes | no