Over the last several weeks I've burned a lot of project time chasing runout, including a vexing flirtation with PROXXON, because this "Minamil" design manages linear motion more precisely than a lot of rotary tools can manage the sharp end of a cutting bit. Actually, I was burning time chasing runout before that, which was why I layed down the (virtual) cash for a PROXXON "Professional Rotary Tool IBS/E" and its promise of <1mil runout (at the collet).

Runout being the "wobble" of a thing that's supposed to be round and revolve around its own center but in reality never is or does. The bits I'm using are close enough to round but the rotary tools I've used for milling spindles (generously interpreted) to spin the bits do not reliably hold bits close enough to the spinning axis of the spindle. That means the pointy ends of cutting bits that are supposed to spin on a point instead get swung around in little circles that are often not little enough.

The really horrible part about lesser (i.e. le$$er) tools is that because they hold bits so randomly, they're occasionally dreadfully near to perfect, which terribly provokes belief that it can happen again, and maybe will on the next try… tempus ardet.

So... the PROXXON. Runout inside 1mil promised at the collet, with steel 3-jaw collets providing the implied reduction of randomness. And other features for more plausible use as a light duty machine spindle. And quiet.

The first one was great...

...almost.

As for runout, it repeatably held short v-bits close enough to true to make ~5mil cuts through copper plate with a 4mil (0.1mm) v-bit. Close enough for this application. Repeatably - as in chuck up a bit and go. Delightfully tweakless. And quiet.

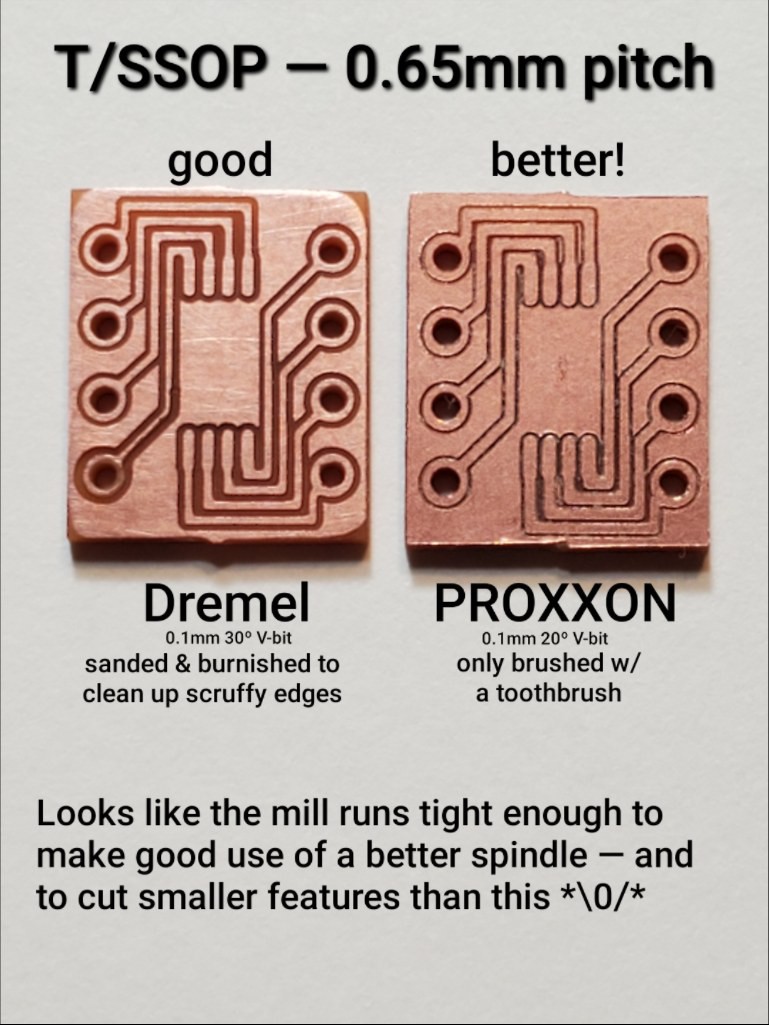

For example:

But...

...axial free play, about 0.2mm (8mil), exceeded lesser tools on hand. Not a big obstacle to milling circuit boards where the two cut depths that matter are just through the copper plate and entirely through the board. But not so great for shaping more subtle surfaces. Especially in comparison with otherwise inferior tools noisily swinging gobs of runout but holding close enough to zero axial play.

Proxxon (enough shoutcase) doesn't actually promise any particular limit to axial free play for that tool. I asked. The only data point I found for comparison was one report of 0.1mm axial play for an IB/E after long use. So I decided to call it a defect and exchange.

The next unit did indeed have less axial play, tho still more than lesser tools. But fail for runout -- about 3mil at the collet and several times more at the end of a short bit. Maybe better than some options, but 3x worse than advertised and the larger swing at the end of even a short bit suggested poor parallelism too. Second exchange.

Third unit no joy neither. Axial play similar to second, which I maybe could live with in exchange for repeatable low runout, and less runout at the collet. But apparently similarly poor parallelism so again swinging big circles (10s of mils/10nths of mm) at the tip of a short bit.

I had both #2 & #3 in hand for a while before shipping #2. (yay Amazon for cross-shipping exchanges) So I burned yet more time swapping & testing collets (several sizes included) & collet nuts between units. Runout seemed to follow collets rather than spindles, so I wondered if it was simply a bad run of collets. Proxxon agreed to send another collet, maybe from a different production run assuming it came from somewhere other than an Amazon warehouse, which seemed about the same as what came with the third unit.

What gives?

Proxxon has generally positive reputation. The first unit was tantalizingly near superb. Are they really this inconsistent? Will they get back to being better after a crap batch flushes through some warehouse? Are they entirely random and I should just keep exchanging? Has the brand simply been gutted and I should forget it? Am I looking at good units with bogus expectations? Is axial play tweakable without a machine shop? Was the first unit an improbable freak that I should have kept as treasure even if only for 2d work? IBS/E owners (or PROXXON Inc.) comment please?

Third exchange? No, I just returned it. Maybe try again in half a year?

Meanwhile…

...back to burning time chasing runout out of lesser (le$$er) tools. At least hopefully finding ways to burn less time at it. And then tweaking spindle speed to minimize resonance between buzzy (because le$$er) tool and c^Hhardboard machine. For proof that a cheap faux-Dremel (+ time & tedium) can do small runout:

Which about got me caught up to where I thought I was in August. :-/

The video linked from the gif above shows fine trace isolation achieved after taking time to tweak the v-bit, then oversized through-holes drilled after burning less time tweaking the drill bit. Pecking those holes first with the carefully set v-bit was an attempt to help a wobbly drill bit start in the right spots. It might have helped with accurate hole placement but didn't stop the wobbly drill from scooping big holes out of the top surface. The exit holes out the other/bottom side of the board are ok.

Contrast with the Proxxon drilling rightly smaller holes after simply swapping in the drill bit and sending it.

So

- the fancy tool isn't essential for fine precision when it's possible to tweak up a lesser tool, but

- tweakless operation was great while it lasted

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.