tl;dr: it works -- scroll for gear example

The proto-concept for this project had a weak Z axis moving the heavy tool horizontally. For reasons, the idea got switched to conventional vertical Z with a counterweight helping the weakly driven axis. And so it was, from then until a post-MRRF epiphany about how my whole concept of Minamil's Z axis has been broken since that early reorientation.

So...

Here's a cheaper, smaller (vs v2.x), stronger Z axis that doesn't need any counterweight:

Because gravity is free anti-backlash (for a << g), and there's room up there to bodge on a bigger motor.

The last log entry showed a lashed-up proof of concept but not yet any attempt to see if it would actually work in anger.

Since then: to CAD and laser cutter... Largely because I'd already planned to try a different arrangement of the slidy parts.

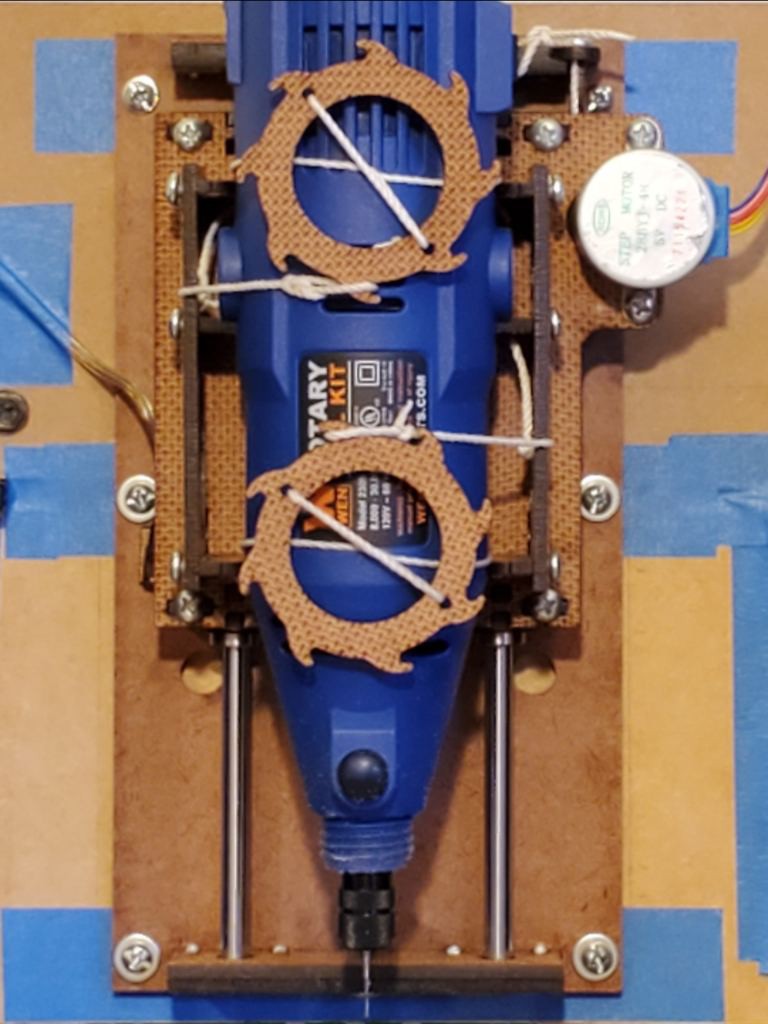

Behold: Z v3

Trading a ~$10 stepper+leadscrew unit for a ~$2 geared stepper, the ubiquitous cheapous 28BYJ-48:

The motor turns a laminated (big disk/little disk/big disk) winch drum to haul the carriage up a bit of string that seems to be sufficiently unstretchy.

The result is surplus torque and steps/mm, so the next rev can use a larger diameter to get more (all?) of the string wound onto the drum in a single helix of more nearly uniform diameter. Currently the steps/mm changes when the string fills the (thin) drum and winds back over itself -- but that won't really matter until someone tries cutting much thicker stuff than I have so far.

Result: yes

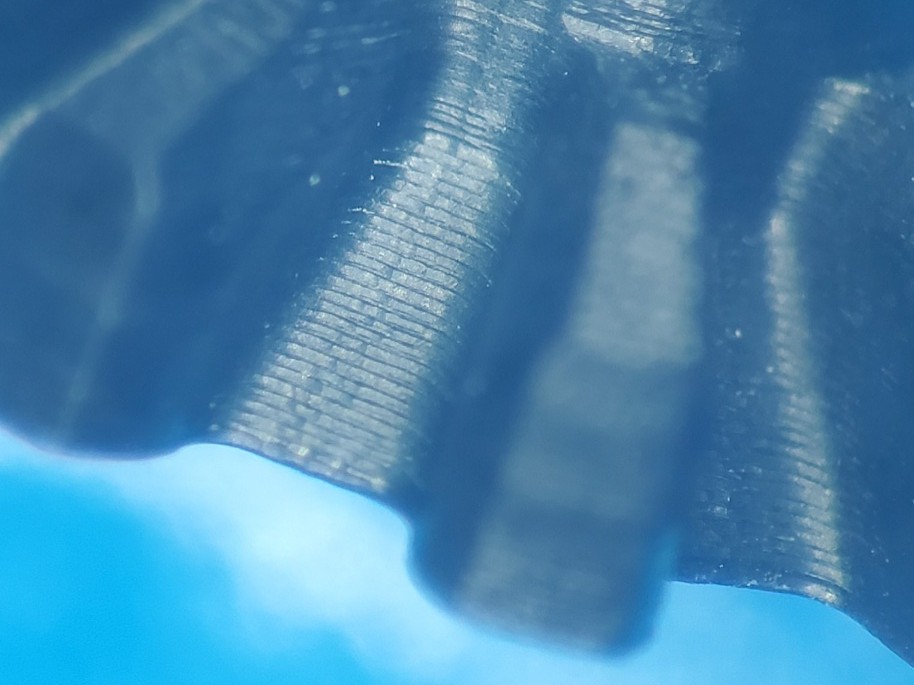

For a first "real" test, I tried cutting one of the little bevel gears from the recently shrunk demonstration project:

Those look like encouragingly uniform 50 μm step-downs. That's really the main point of this log entry. ☺

Besides losing all the counterweight rigging, this version gains some other wins:

- reduced cost

- top of the machine is solid when not holding the rotary tool (vs. moving/fragile parts)

- longer range of motion (>70mm -- obstructed to ~66mm by limit switch in this rev)

- smaller/shorter than V2.x slides

- stiffer than V1.x slides, and I think not much less stiff than V2.x

- operates without tool mounted and counterweight rigged (or a finger under the empty carriage)

- option of using two longer rods vs 3x 100mm rods, or one long+one short; four bearings on two long rods should better resist twisting of the tool carriage

- long rods, if used, supported in middle to maintain stiffness -- otherwise prolly too long for 6mm

For reference/comparison/contrast:

V1.x

(lame photo)

Uses same slide mechanics as X & Y. Most compact.

V2.x

(also lame photo)

Mechanically based on two copies of the X/Y slide in tandem. Because that seemed like a thing to try. Much larger than v1.x. Used relaxed size constraint (XY axes limit minimum footprint area) to spread out the bearings for greater stiffness - probably well into diminishing returns. Lower two bearings spread 1/3 wider. Upper bearing much higher above lower bearings relative to v1.x, especially in upper range of motion. Room for two motors+screw units, but didn't try/need that in Z with counterbalance and mild acceleration. Added a lot of height overall. The long tail of the moving tool carriage stuck up vulnerably from the top, while the "telescoping" configuration didn't add any benefit for this axis -- reasons why the next rev was going to drop the telescopiness for a less unconventional arrangement of bearings in a shorter tool carriage running on axially offset rods in a similar tandem base.

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I totally agree with the kit idea: inexpensive, easy and accurate. Sign me up for one!

Also, it would be nice to have a 3D-printable version of the axes slides; access to a 3D printer is super easy - much more than a CO2 laser. Printed out of, say, fiberglass nylon, it would be great and even easier to assemble. Just a thought... 🙂

Are you sure? yes | no

Beautiful! This version looks refined enough to start selling kits.

Are you sure? yes | no

Thanks! I started this with no expectation that the result would be worth the overhead of kitting and re-shipping parts. Now that it seems there are some (small) things it can do well, maybe a kit could have more value than I thought. ¯\_(ツ)_/¯

Are you sure? yes | no