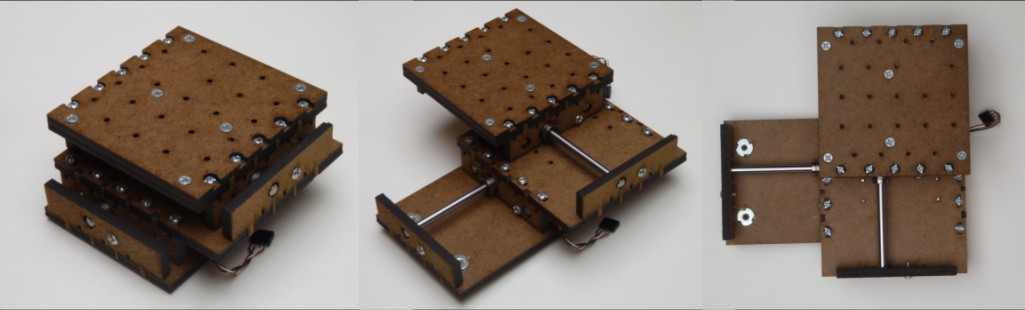

The next rev of the XY table improves, I hope, in some respects other than looking good. So I took some beauty shots before gutting the first one. This seems like a good time to say a little about the mechanical design-in-progress.

Or: "6mm rod starts at 100mm; what could I do with that?"

The next rev continues this basic arrangement.

Spoil board replaceable without messing with anything else. The initial cut job could include extras. The screws within the work area could be:

- omitted

- countersunk more deeply

- swapped for shorter screws with smaller/flatter flat heads.

- swapped and sunk deeper

Integrated workholding:

Including burried nuts, adjustable corner fence, and some clamps. The fence can slide in to (0,0) or out to align material with some margin around the work area. The little clamps work at the edge of the table. I made more of the larger clamps to use when not trying to hold material close to the table edge. The hole spacing is a little sparse, so the larger clamps have short- and long-reach positions for the back screw while the clamping screw runs in a slot. The fence and clamps fit within the tabletop area while holding 60mm x 60mm material -- but that's overconstrained because the footprint allows some overhang of the two "far" sides. The cap screws+toothy ferrules work for finger tightening, sometimes, depending on hand space & angle of access, fingertip cleanliness, etc.

While I like this idea and hope to get back to it, the next rev omits all the tastey workholding goodness & reverts to double-stick tape. Other fish to fry.

About telescoping axes

I don't know of other CNC machines using a similar arrangement. If you do, please comment. I'd love to hear what textbook/reference already has all the answers that matter. For this particular combination of 89mm long actuator w/~60mm throw, 100mm rods & ~3mm thick material, it seems like a good way to get long travel in a compact footprint with stiffness varying in an acceptable range. I hope to work through a more careful comparison with the more usual two-bearings-on-a-rod+roll-constraint arrangement but it's time to post this and sleep.

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.