We opted for fixed blades, meaning the blades are attached to the axle. Disadvantages of adjustable blades, like being prone to damage and increased material and maintenance costs do not add up to the advantage of having the blade angle perfect everytime. Also, a near-perfect blade can be made by twisting the blade along its length. Because of this, fixed blades have become the mainstream in the wind DIY-community.

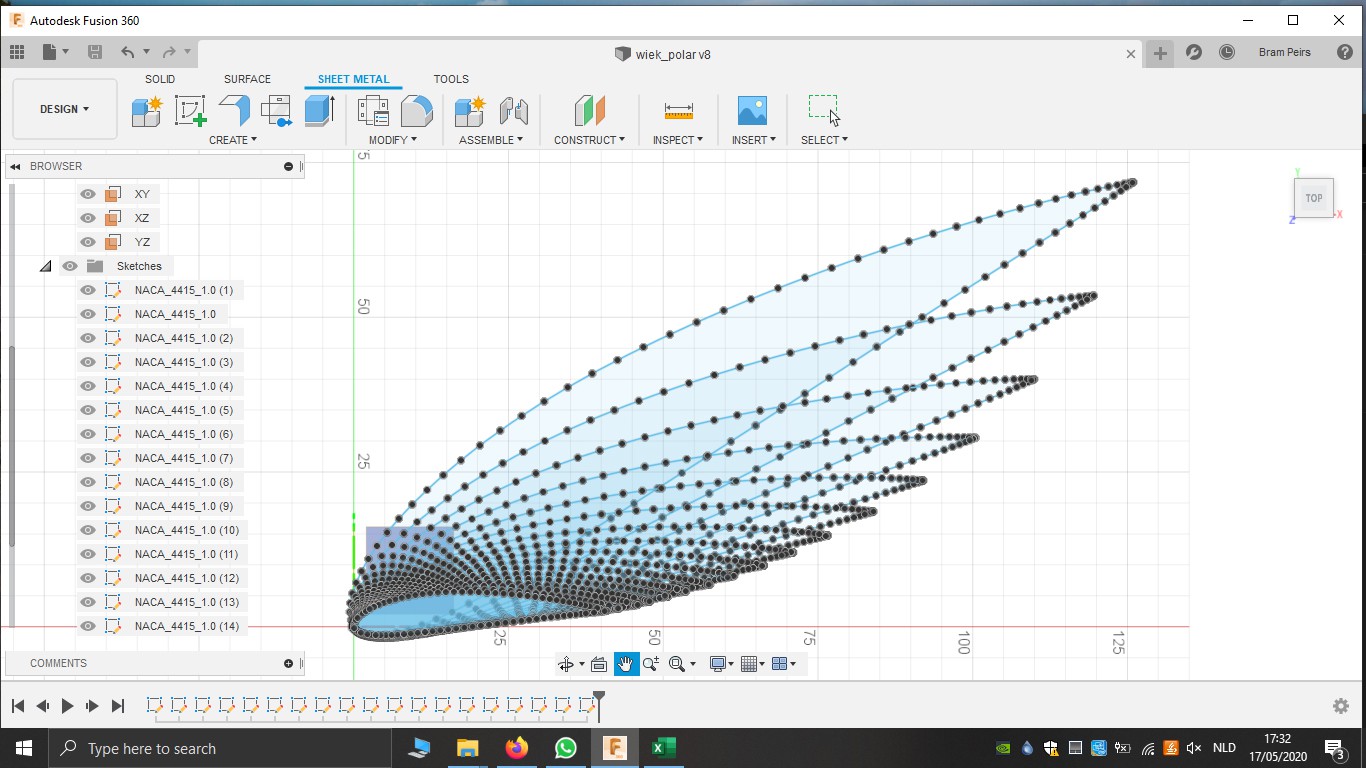

To be sure we have the correct twist and taper, we used Hugh Piggot's Blade Design spreadsheet. Furthermore we choose the NACA 4415 airfoil for its good suitability for small windturbines.

We modeled the entire blade in Fusion360, with some small tweaks in 3DS Max:

Bram Peirs @ FW2W

Bram Peirs @ FW2W

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.