Tesla Key Watch

Inspiration

Before getting into the nitty gritty details of this project I want to thank two people that helped me a lot and inspired me:

- Darconeous for researching the Tesla Key Card protocol and creating the awesome Gauss-Key-Card project

- N-O-D-E for inspiring me with this build and sharing his files.

Without these two this project wouldn't have been possible.

Rationale

Let's start with the usual: "I love my X but...", in this case the "X" is my Tesla Model 3 and the itch I cannot scratch is that, from time to time, the keyless entry doesn't work as expected. This usually happens in the worst of circumstances (Water is pouring from the sky? Well I won't open for you sorry...). Something hacky was needed....

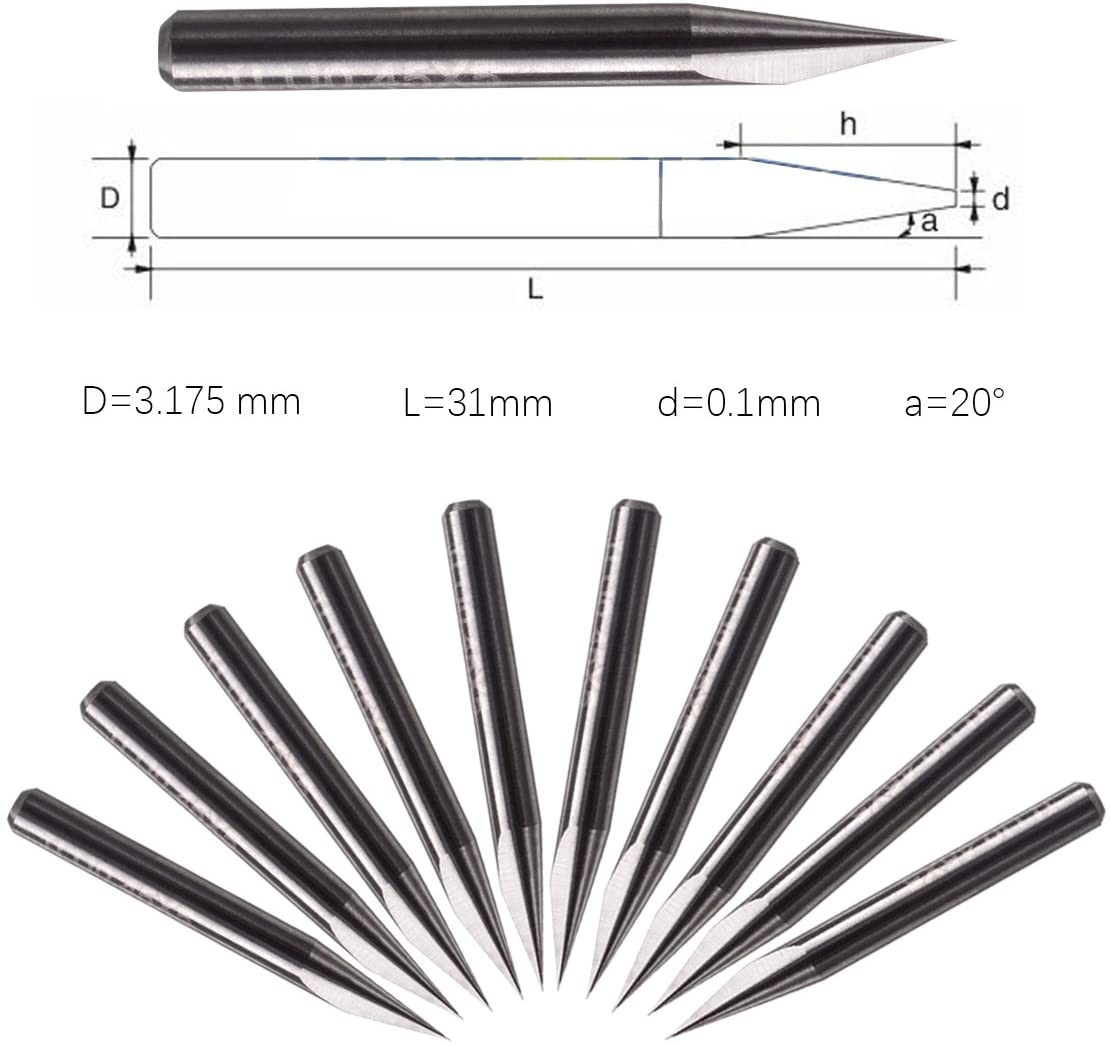

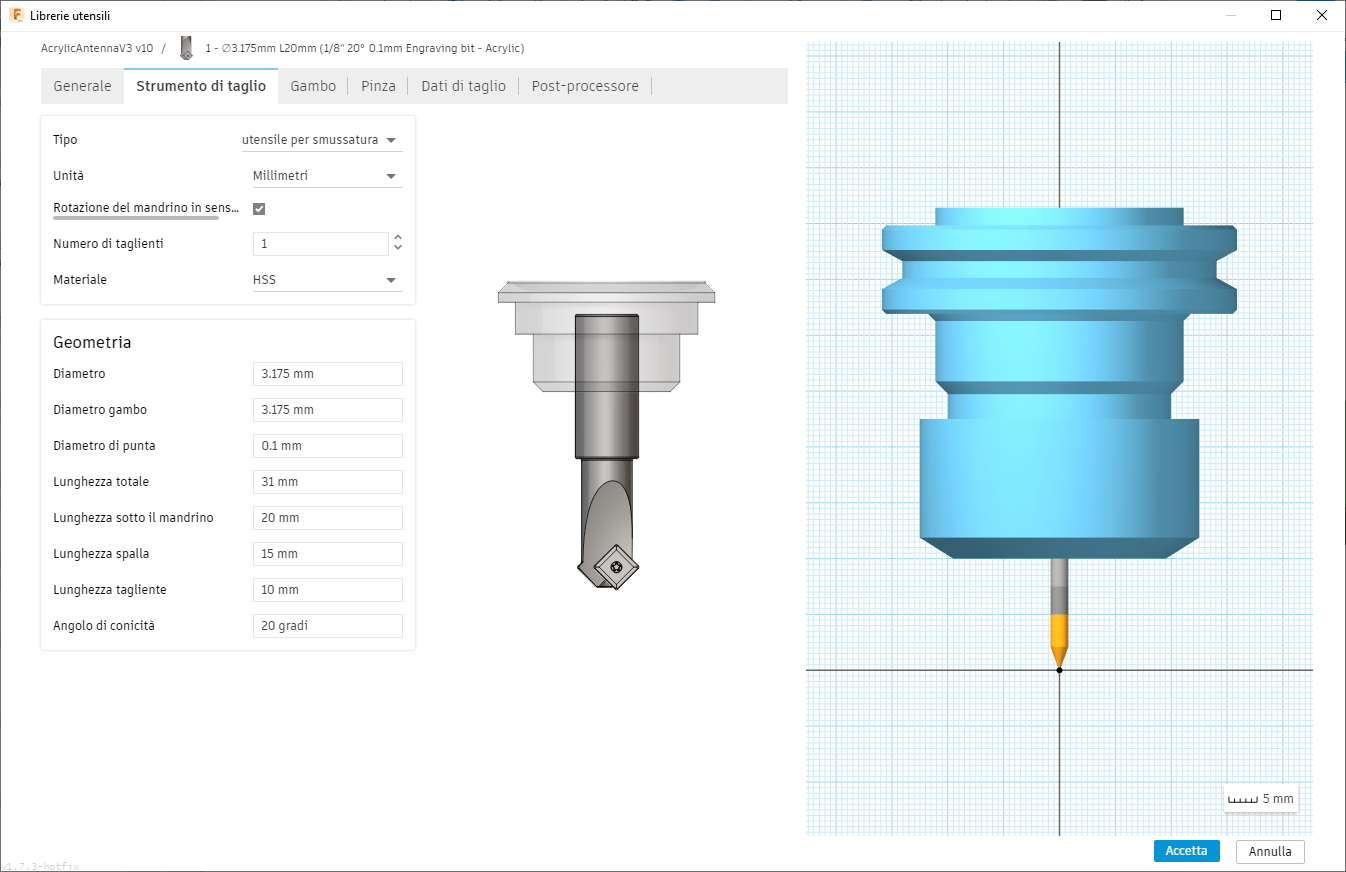

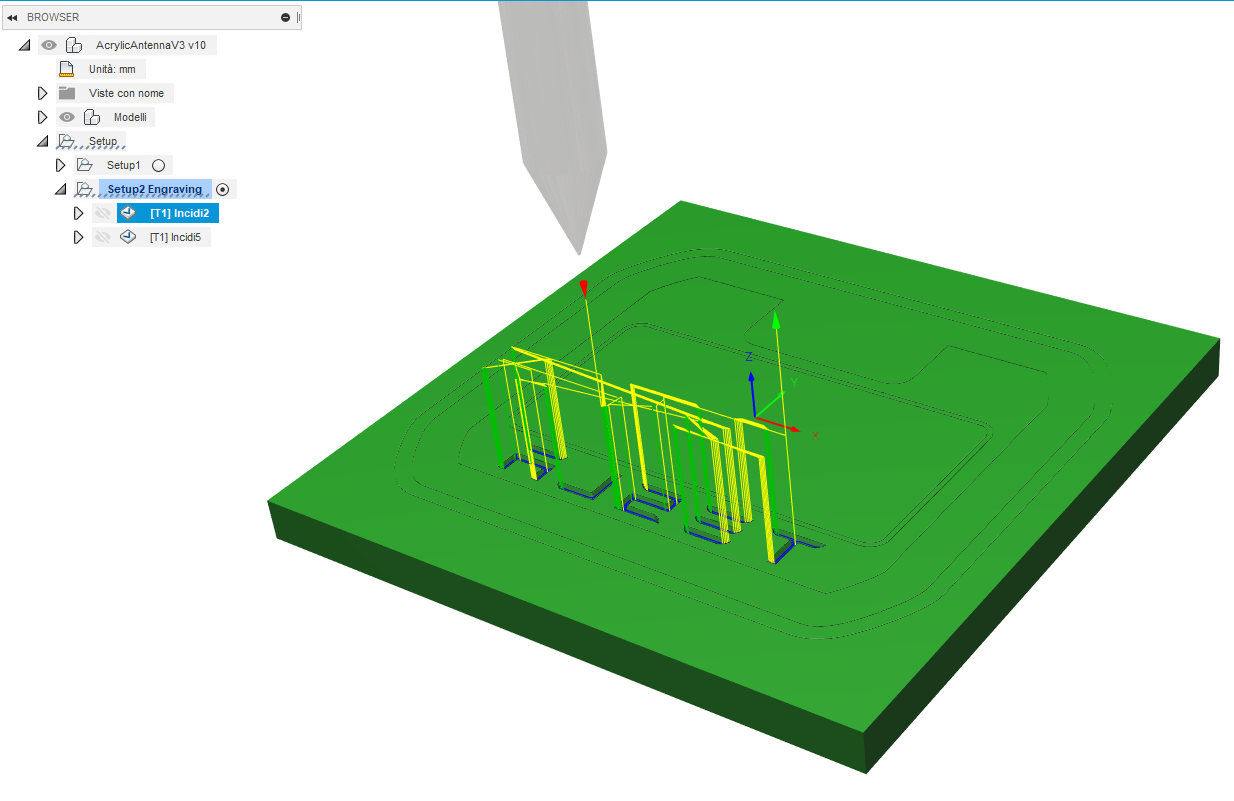

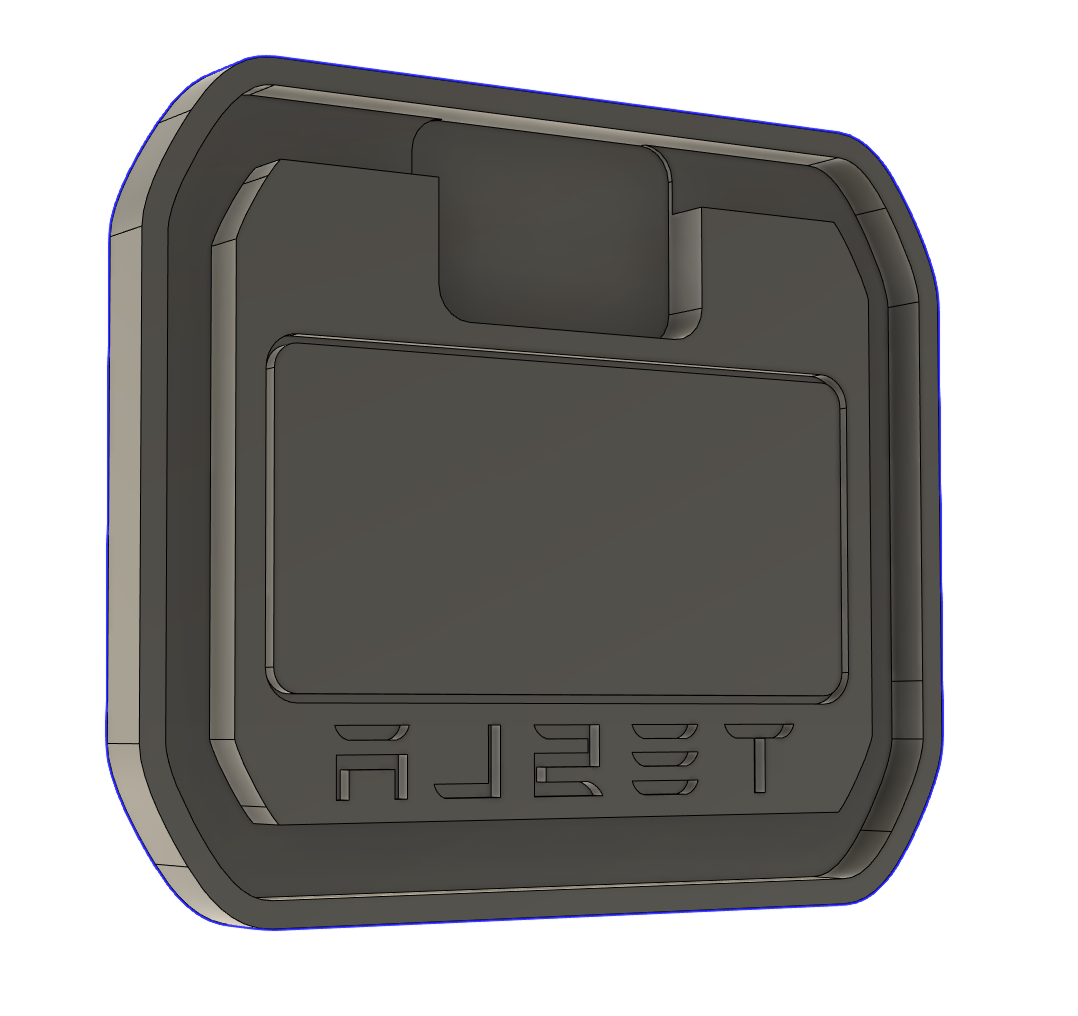

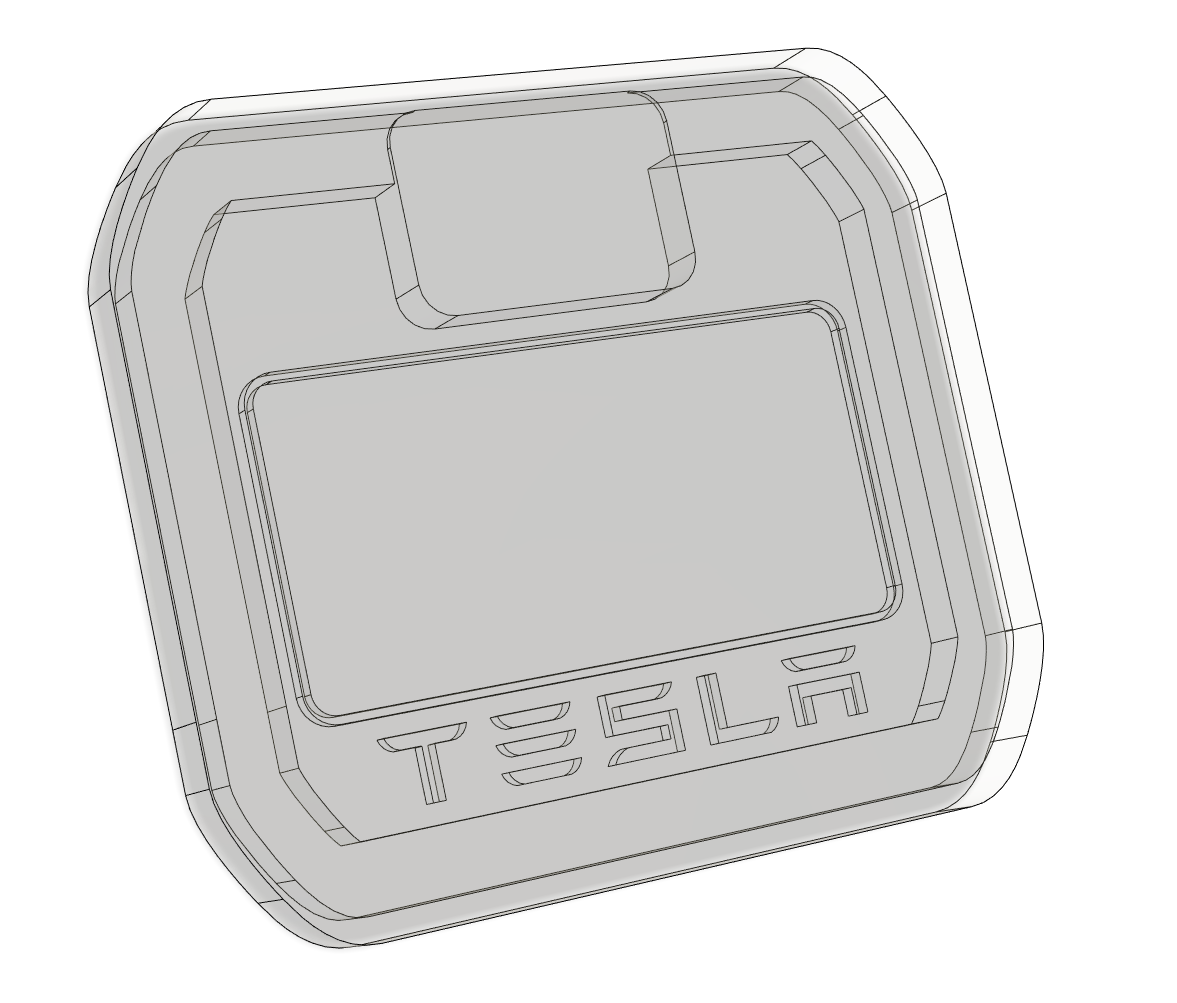

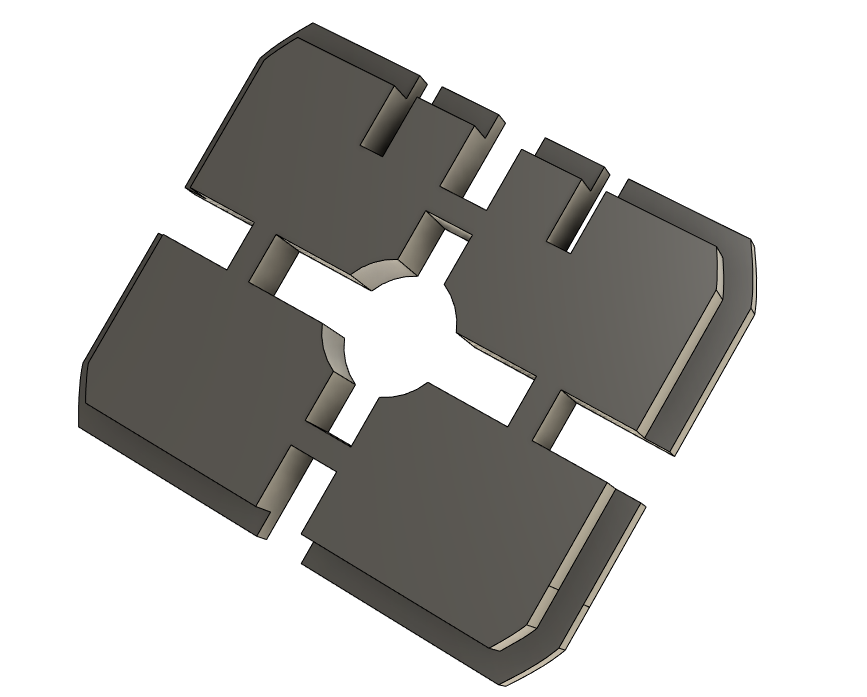

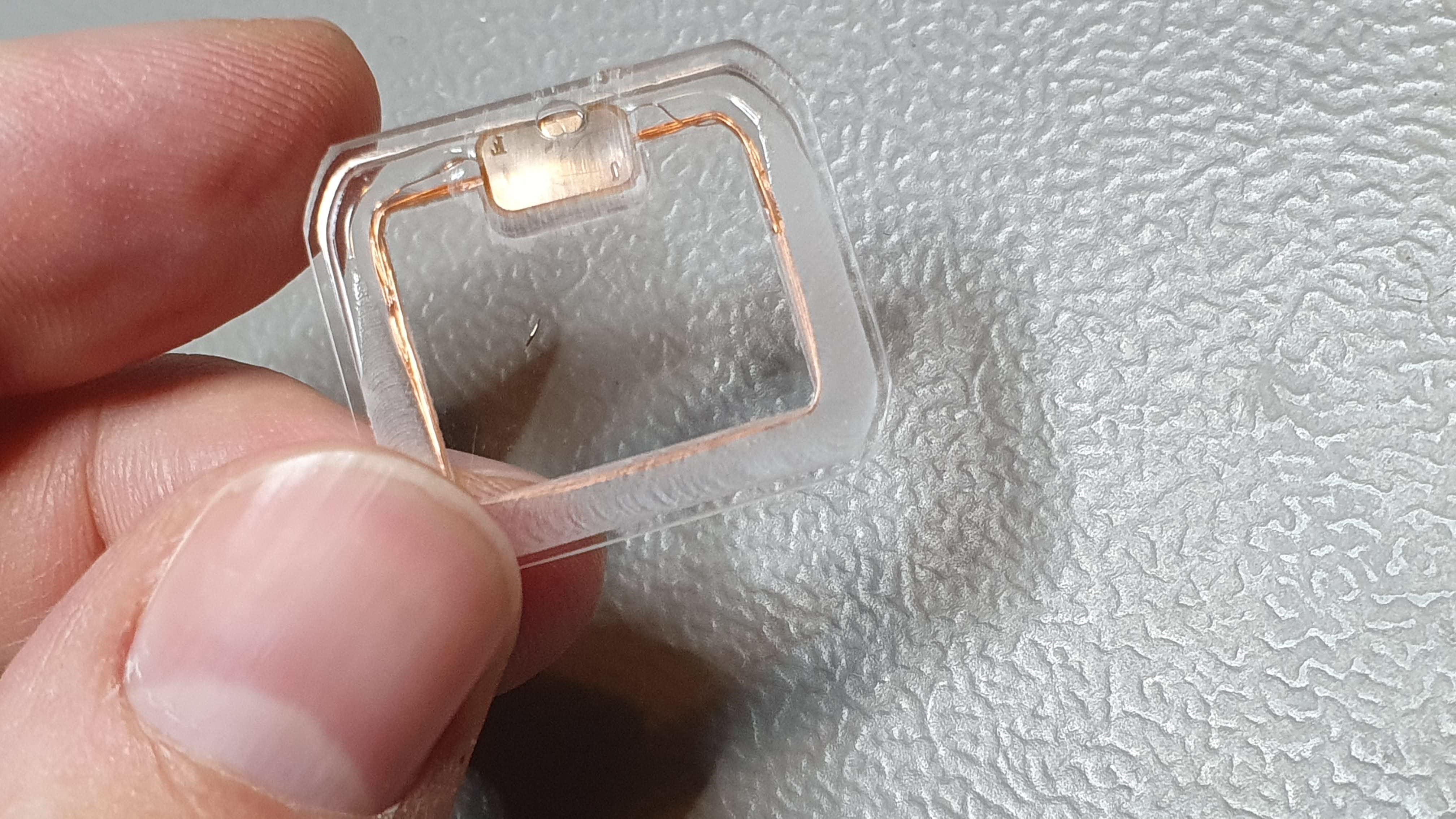

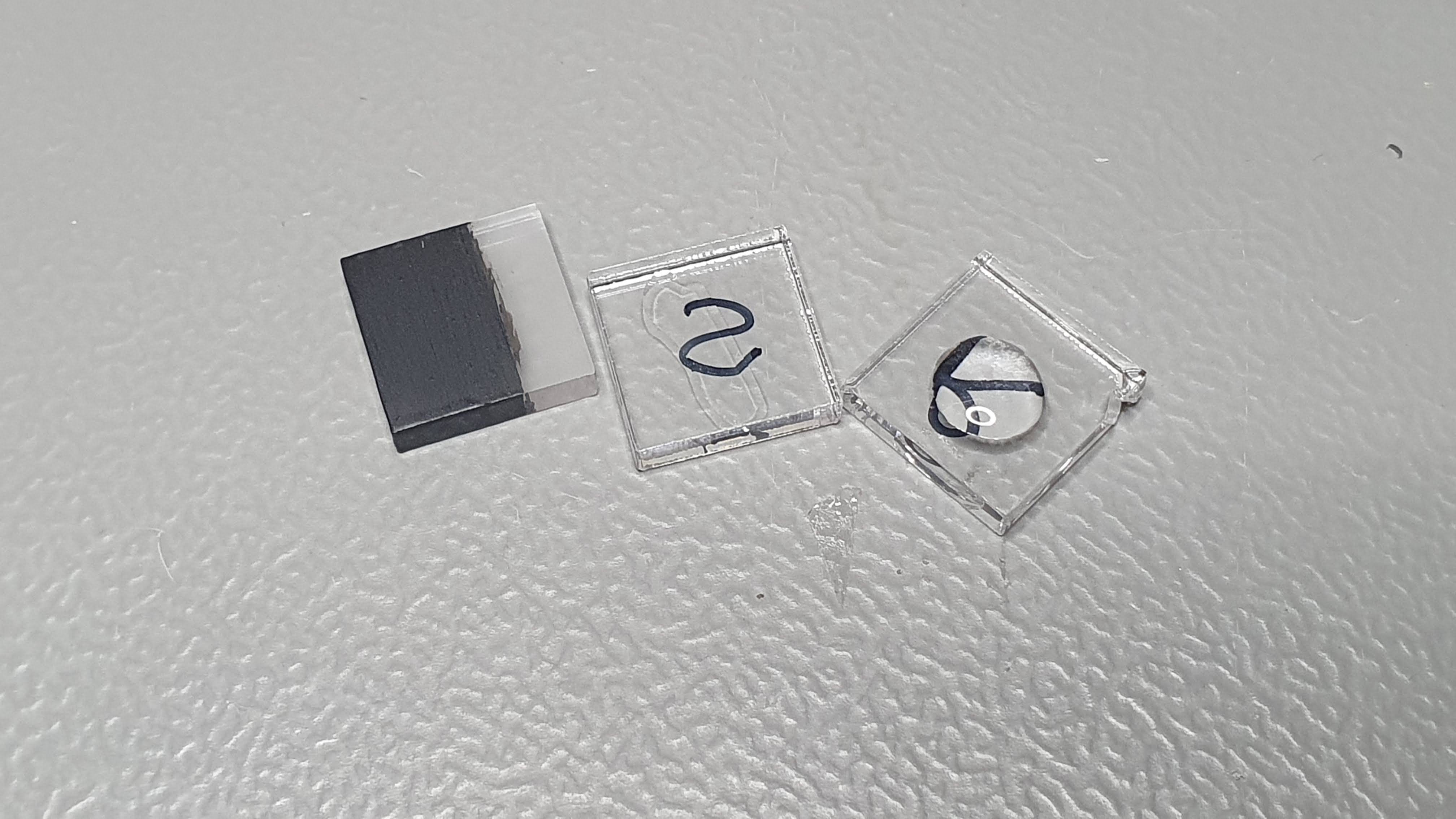

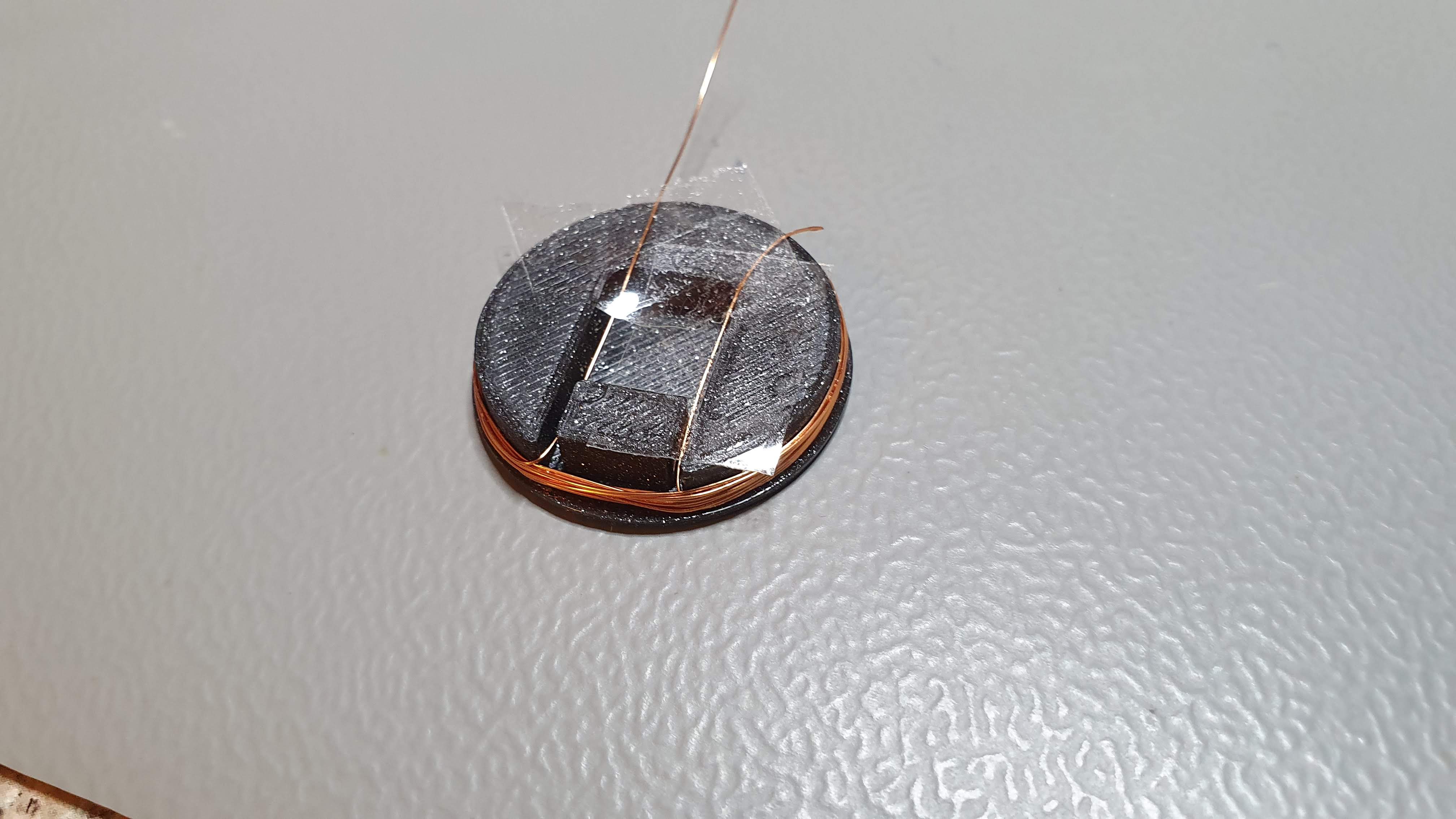

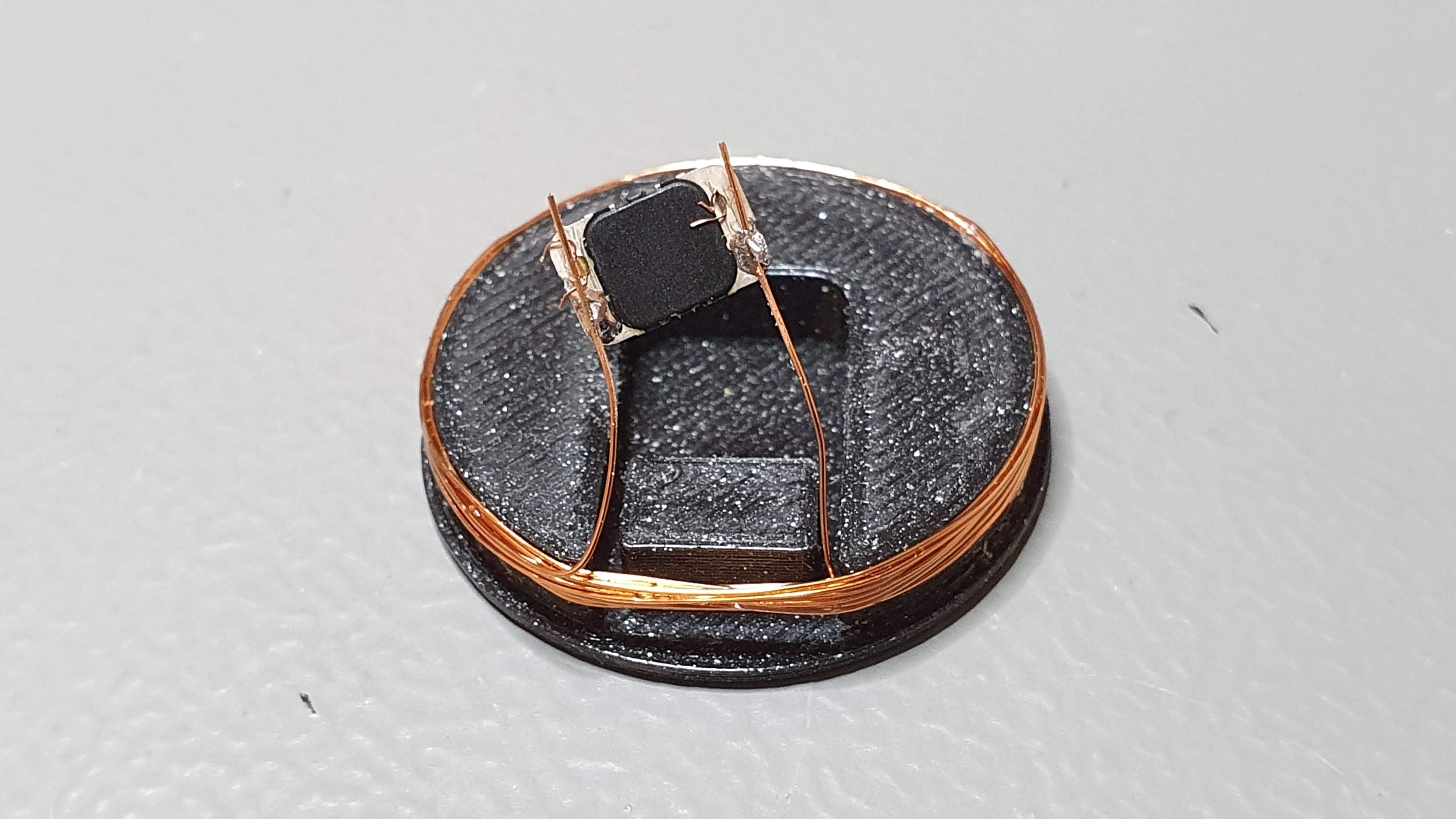

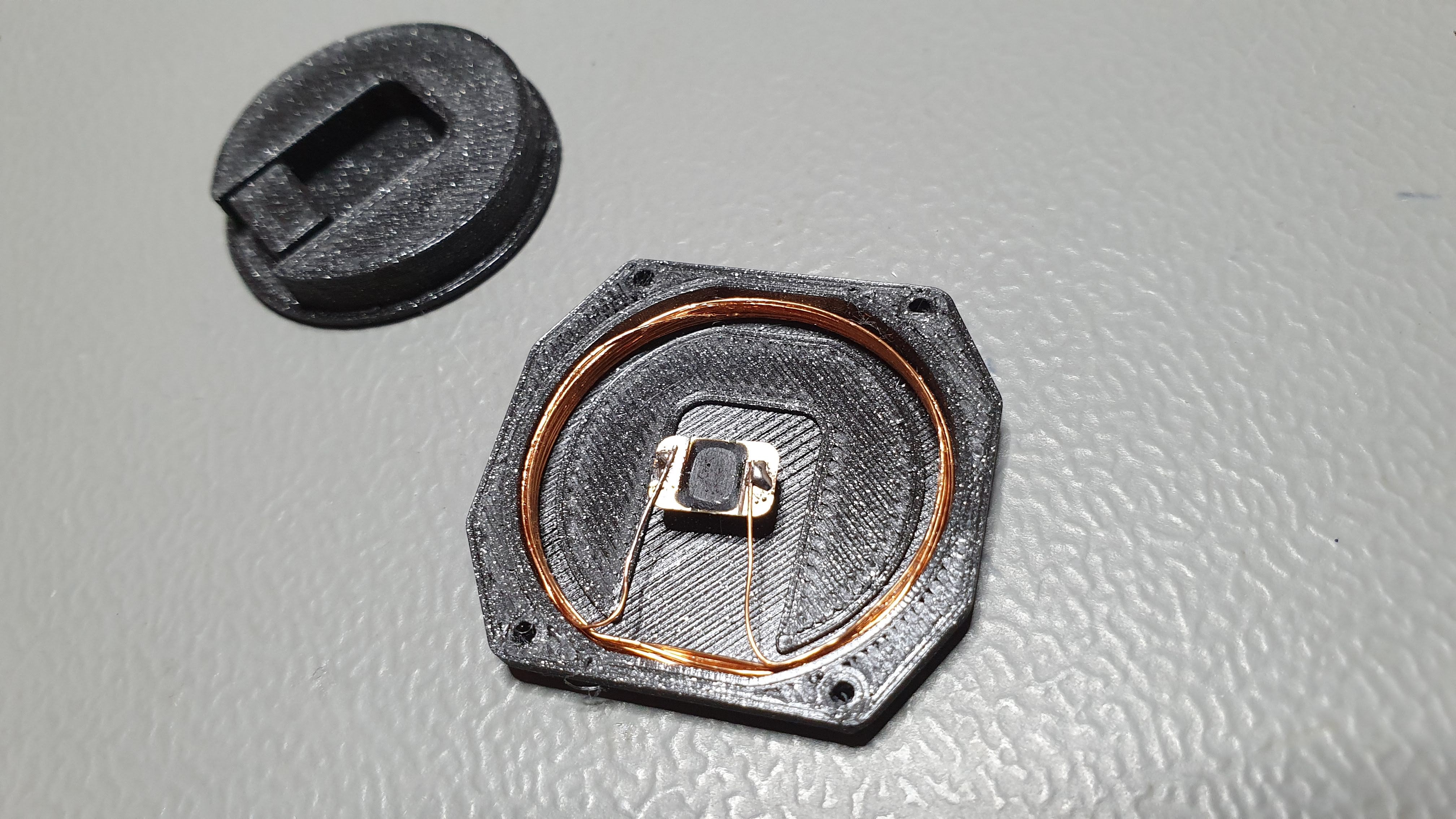

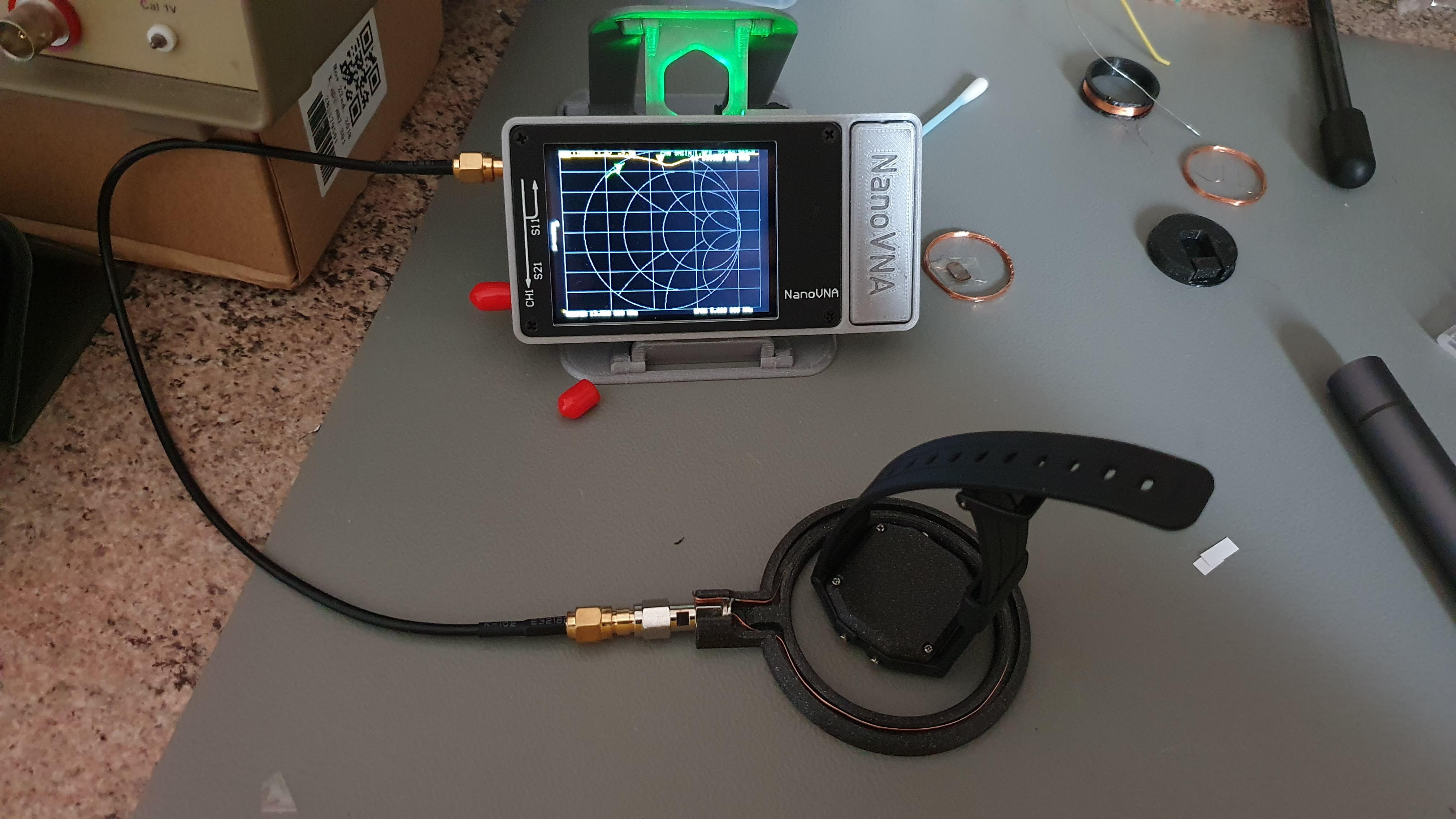

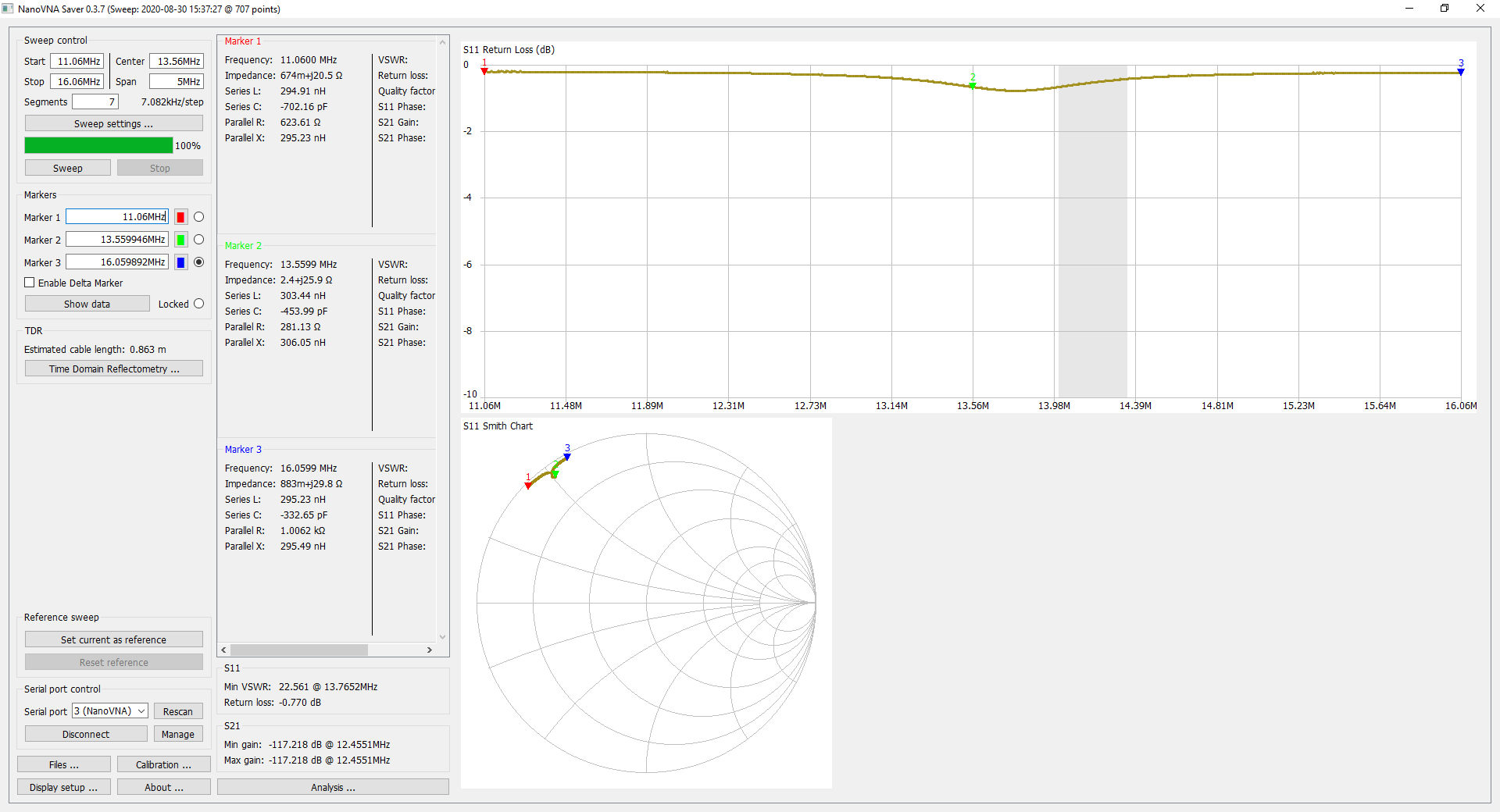

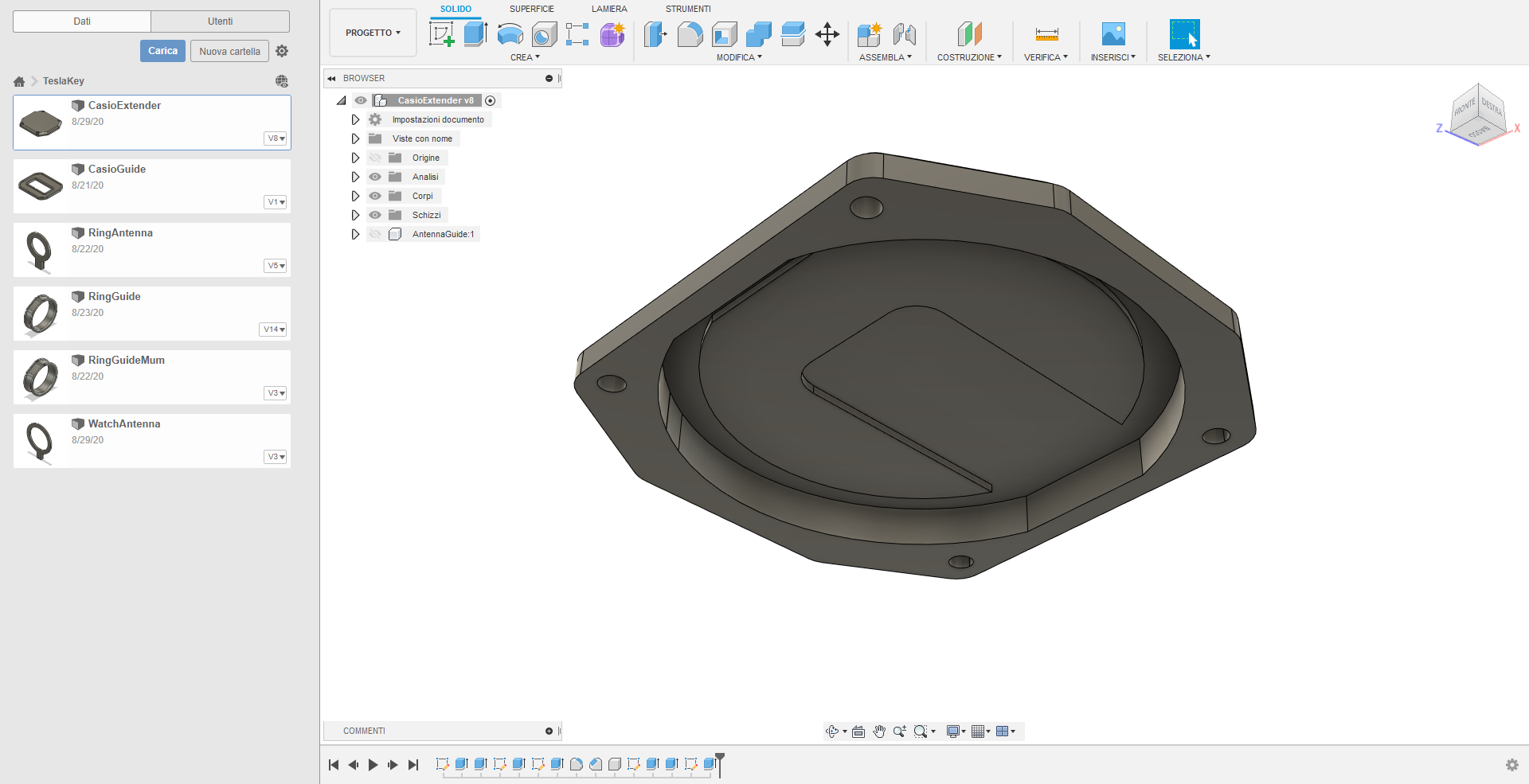

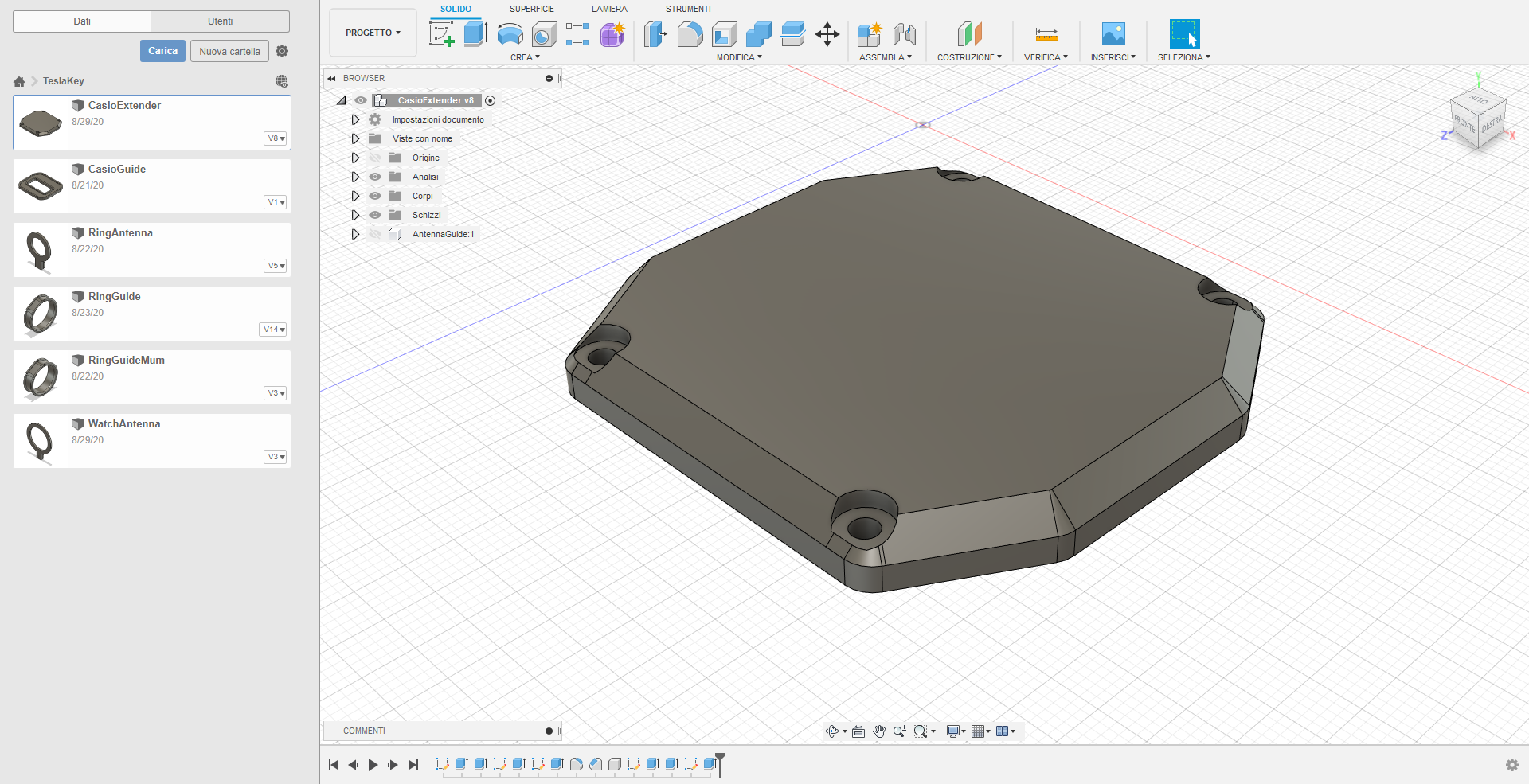

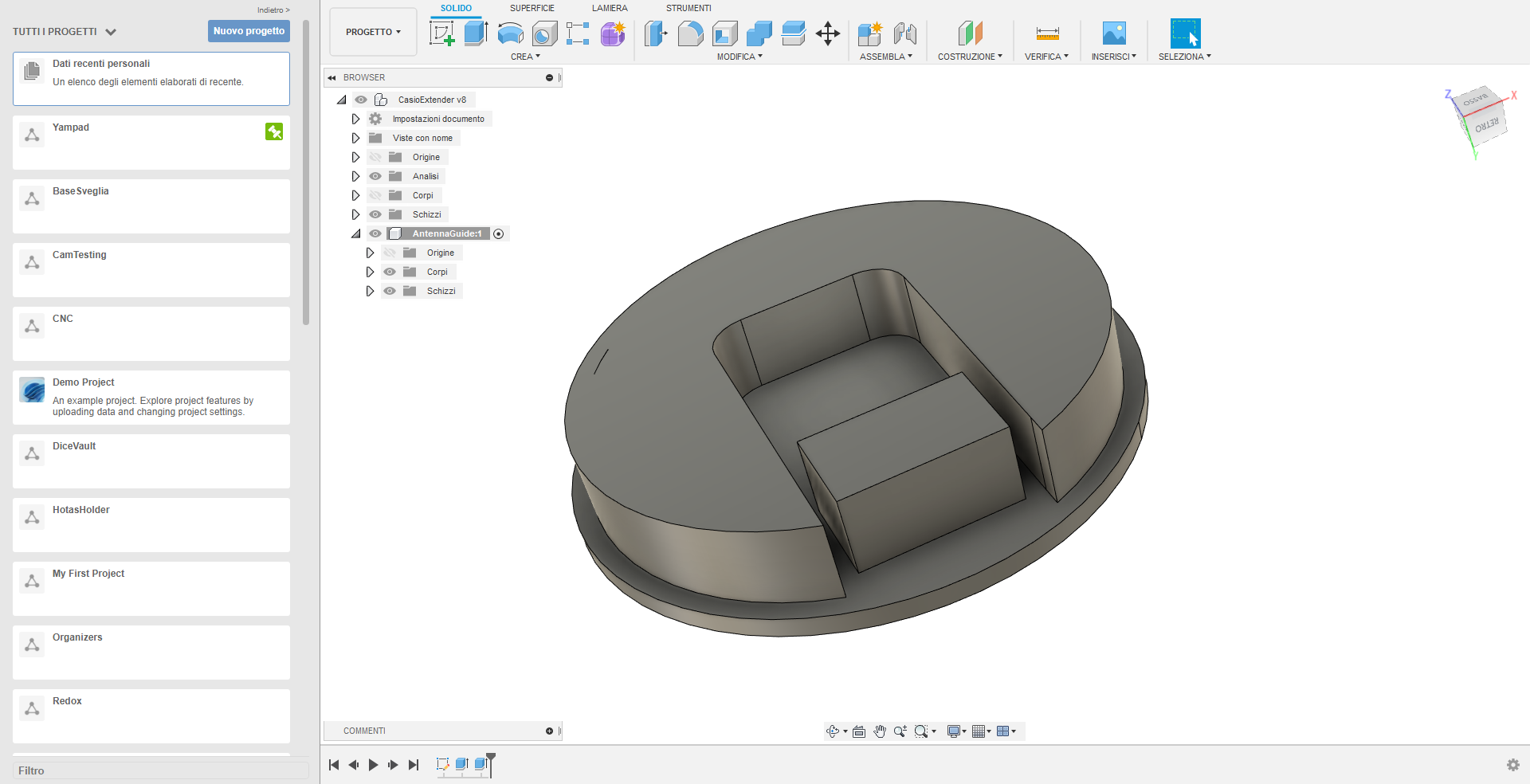

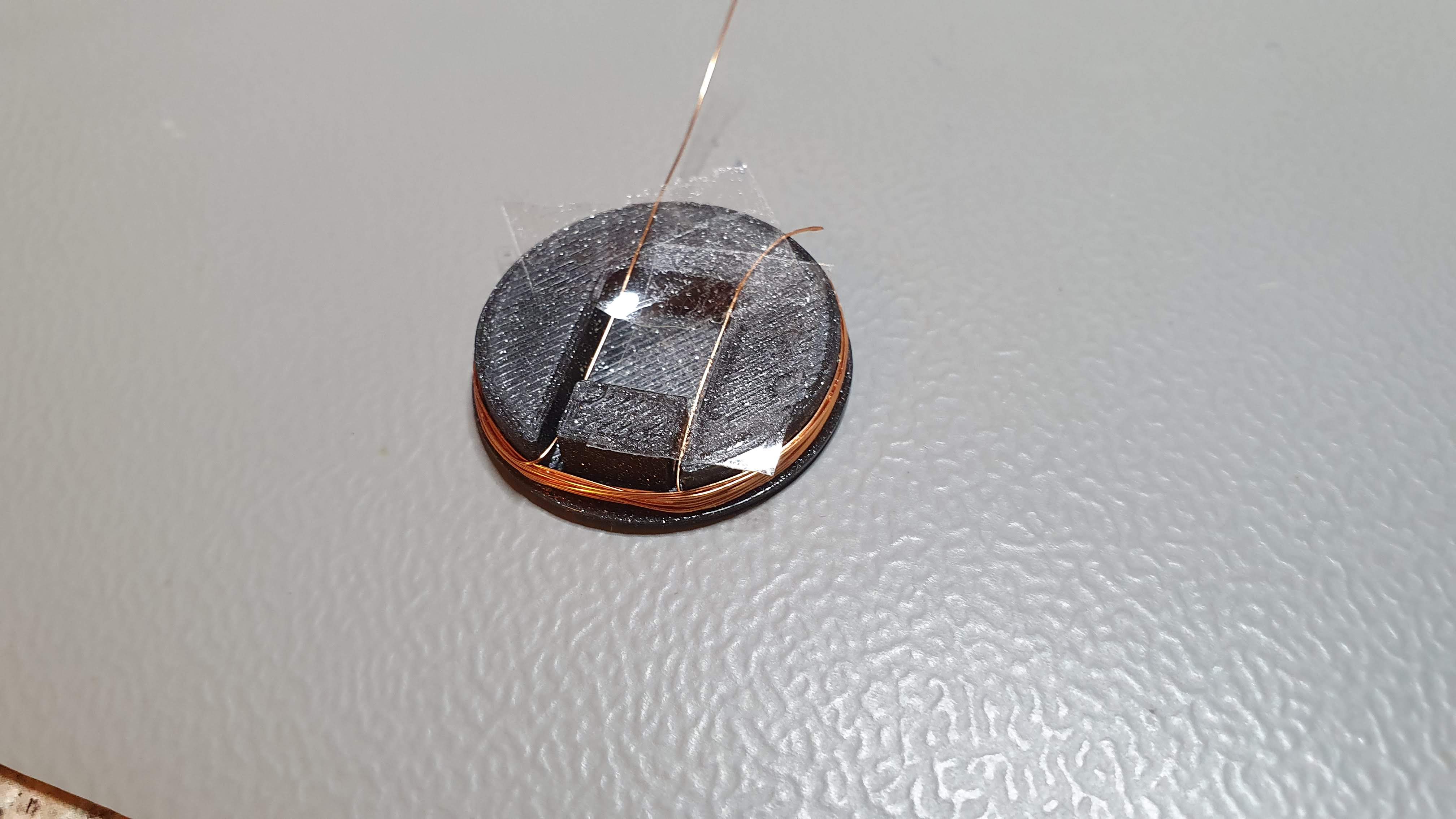

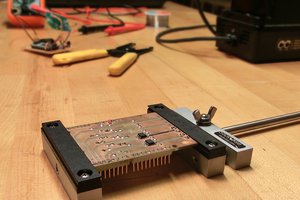

The main inspiration for this project came from N-O-D-E and his Data Runner watch. After seeing it I decided I wanted to open my car using my watch. Researching the project I came accross the Gauss-Key-Card project and decided to follow Darconeous steps by making my own matched antenna for a J3A040-CL card from Smartcard Focus. I didn't want to use an official Tesla card for this because the phone call to request a duplicate, if things went south, would have been quite awkward. I didn't want to use the PCB antenna from the Data Runner watch either, because the J3A040-CL antenna matching could be way off, compromising usability. So, custom hand-crafted antenna it is.

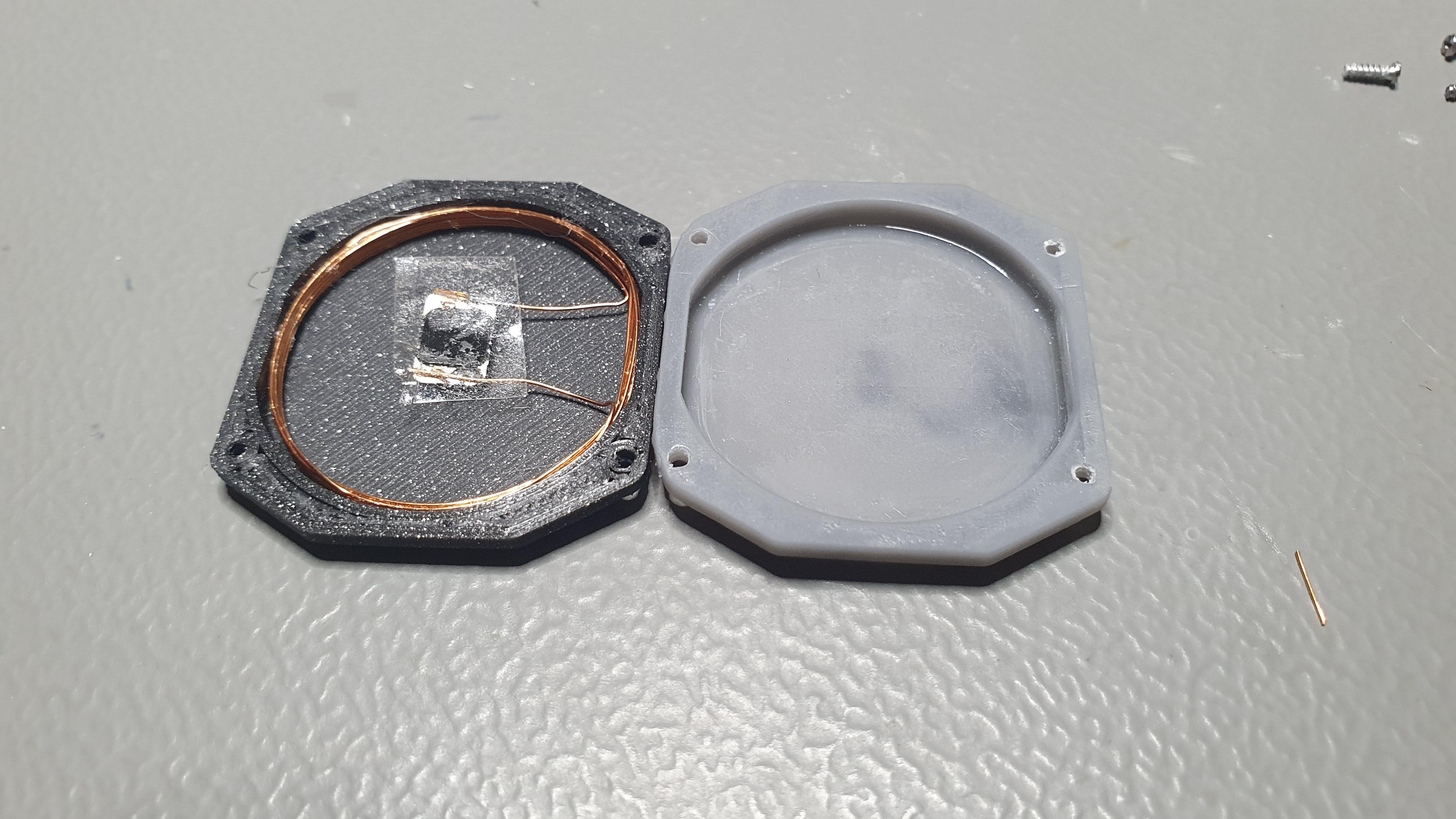

Version 1: backplate antenna

I'm quite happy with the results. The NFC communication is quite good and usable even in a pinch (more than taking out my phone or the key card from my wallet for sure) and the watch is comfortable to wear almost as it was before.

The fact that the mod is completely hidden is a big plus to me. You wouldn't know the watch act as a key from the look alone, and once worn the chassis modifications can't be seen.

Improvements

As always there's things that can be improved on:

- The watch is almost as comfortable to wear as before. "Almost" is the key word. It scratches a little on the side where the layers of the 3d print join near the screws. I'll need to think of a better design or change the medium (a resin cast maybe? transparent would be a lot cool).

- The buzzer was removed with the backplate, would be nice to find a replacement that can fit in the new case. If anybody knows of a buzzer that can be put in place of the standard piezo please tell me!

- The NFC range is good but can always be improved on. N-O-D-E's idea of a PCB antenna is great but we need to take matching into account and without a datasheet to at least go in the neighborhood of 13.56MHz for the resonant frequency we're flying blind. I also considered the removal of some metal parts from inside the watch, but I'm waiting to think of a better alternative before doing destructive modifications to the watch.

- I don't think the watch is water resistant anymore.

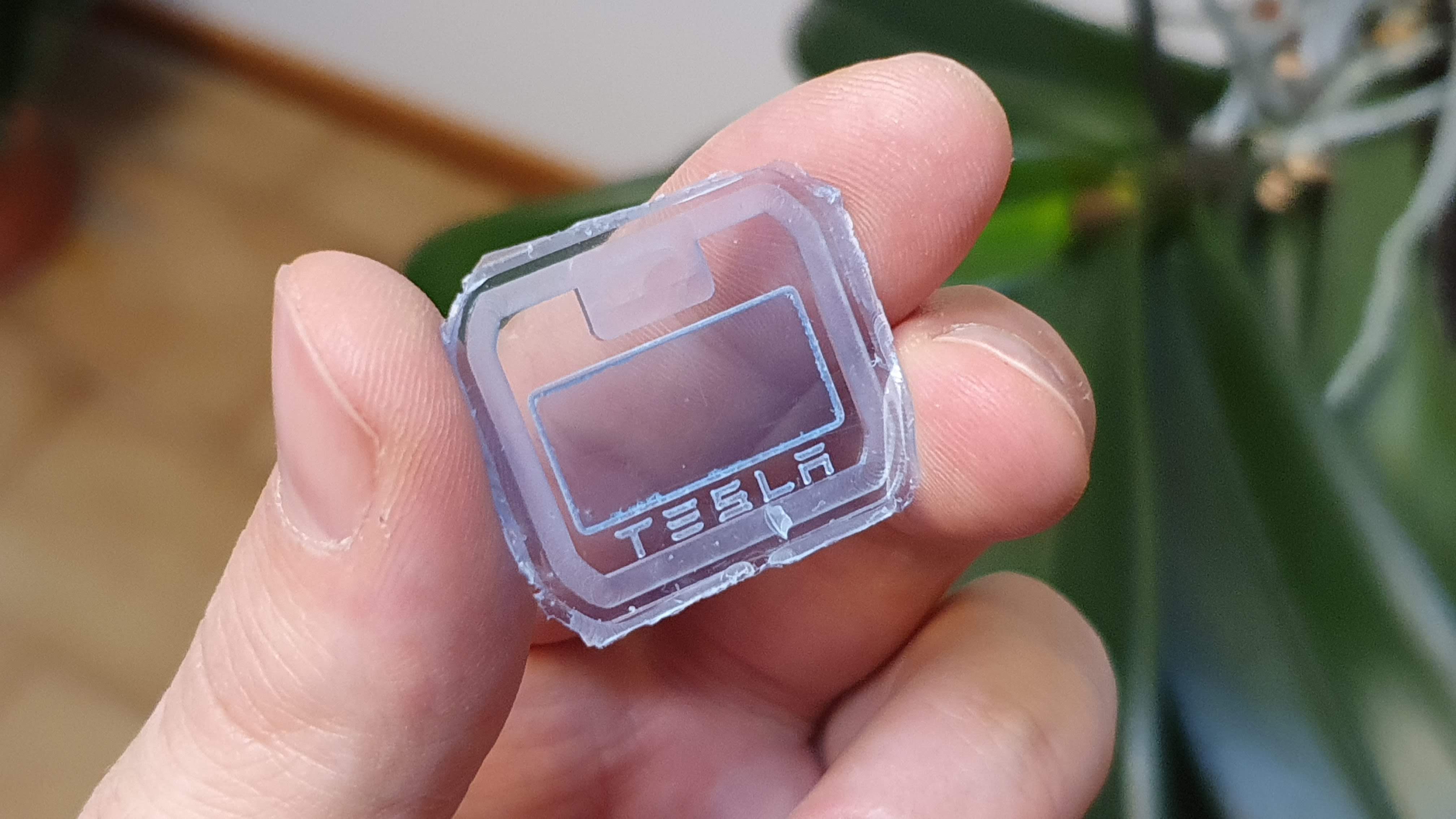

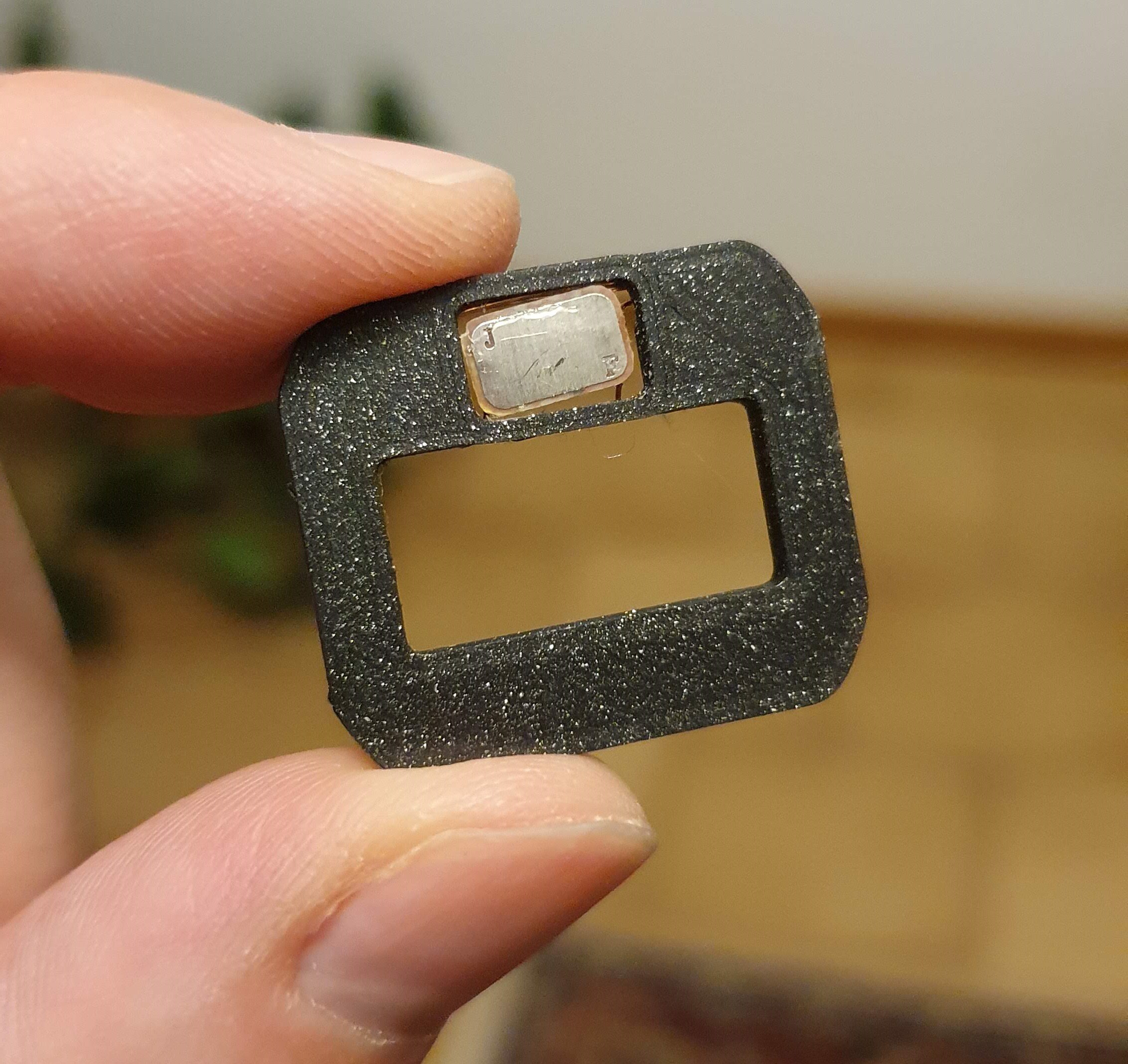

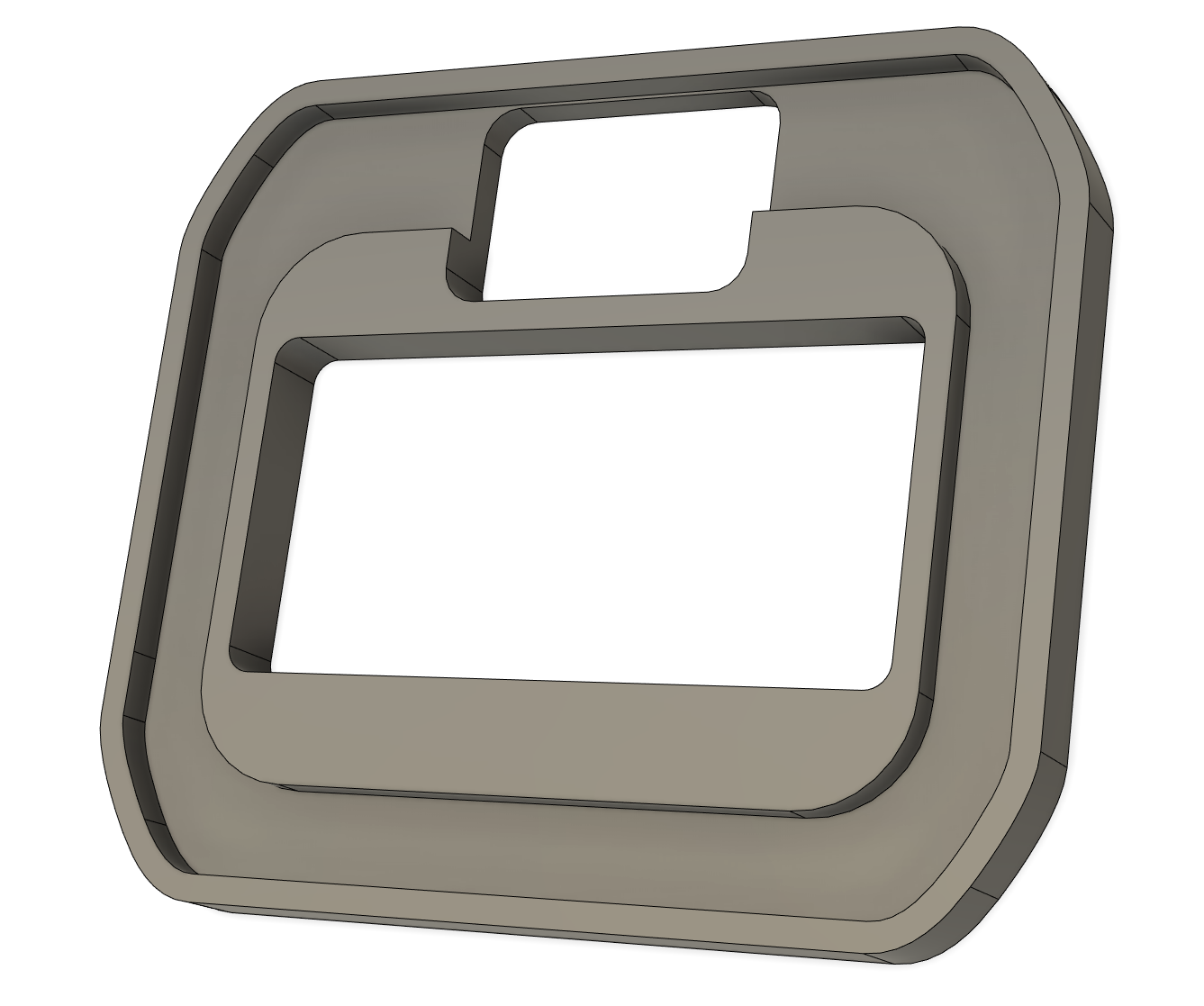

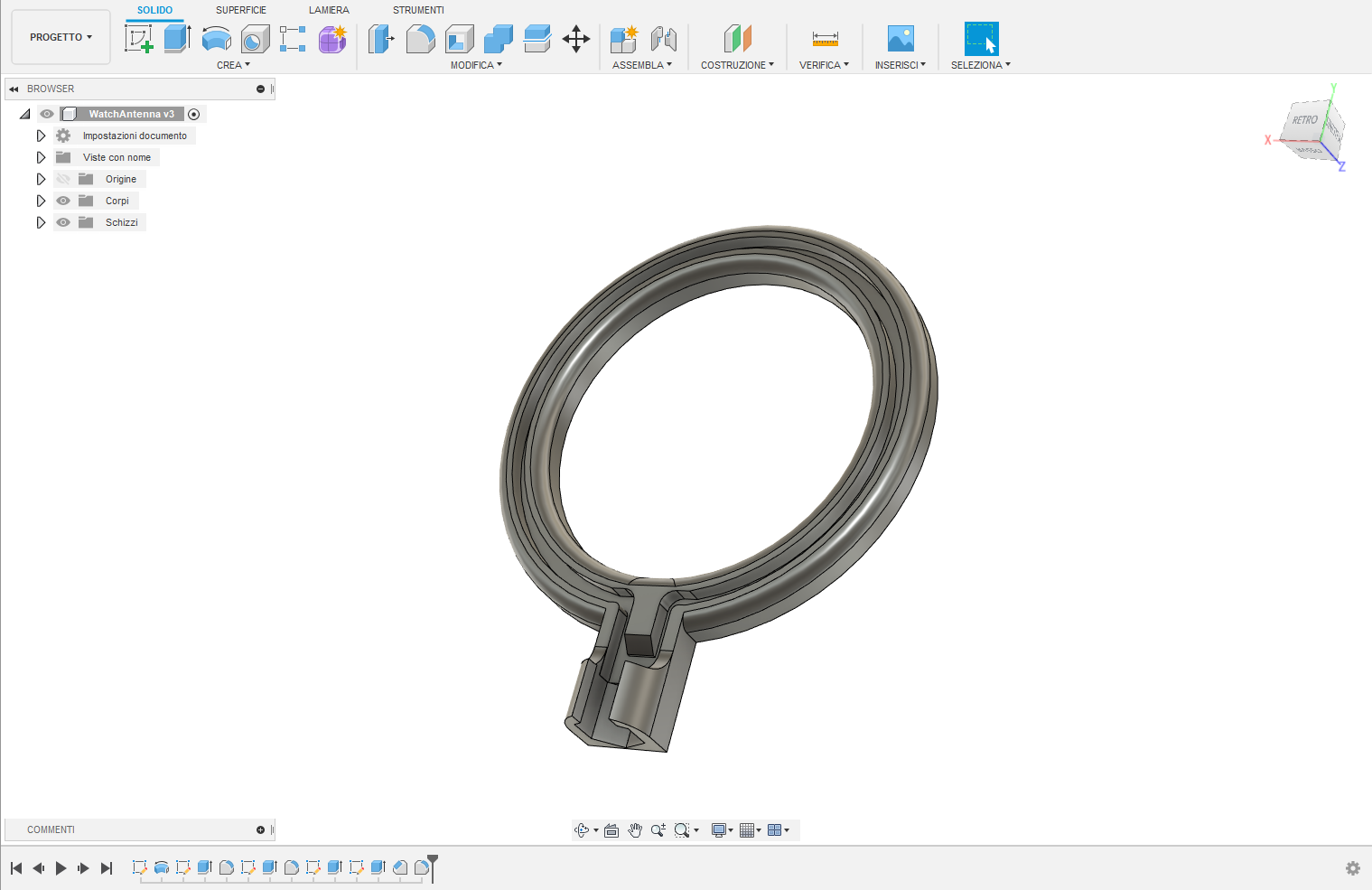

Version 2: frontplate antenna

The second version using a frontplate antenna design improved all the areas discussed above.

- The front placement achieved better range for the NFC communication.

- The backplate was left stock for better comfort and for keeping the buzzer.

- The looks are not so stealthy anymore but I really dig this cyberpunk look with the chip visible and the Tesla logo.

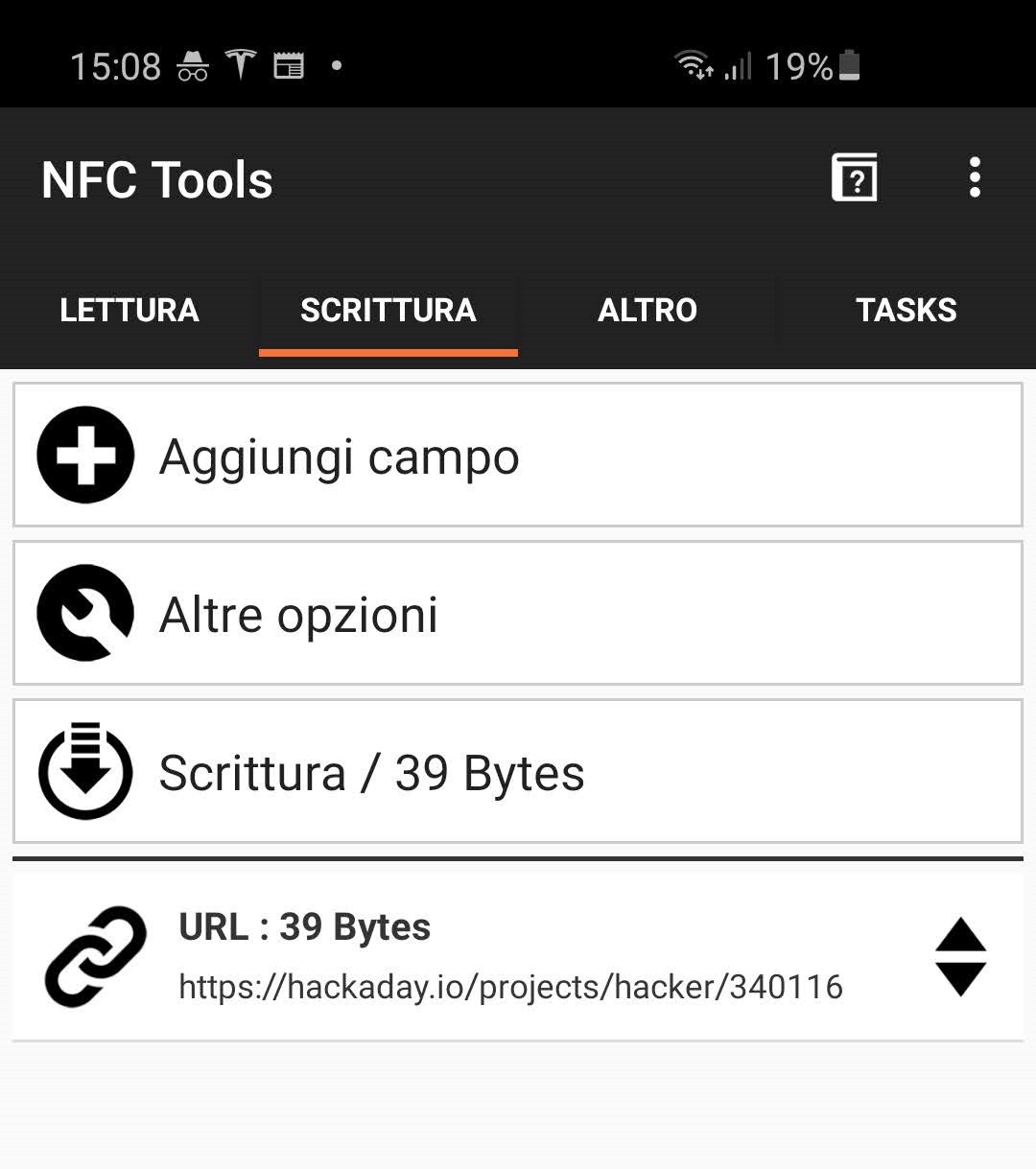

Since I'm wearing this watch at all times and using it regularly for getting in the car I'm thinking about adding some more functionalities to it (NDEF Business Card, use with Yubico Authenticator for generating OATH codes...).

Mattia Dal Ben

Mattia Dal Ben

Mike

Mike

TraceSpazer

TraceSpazer

Alex Rich

Alex Rich

thanks for providing great informationhttps://bestdreambed.co.uk/