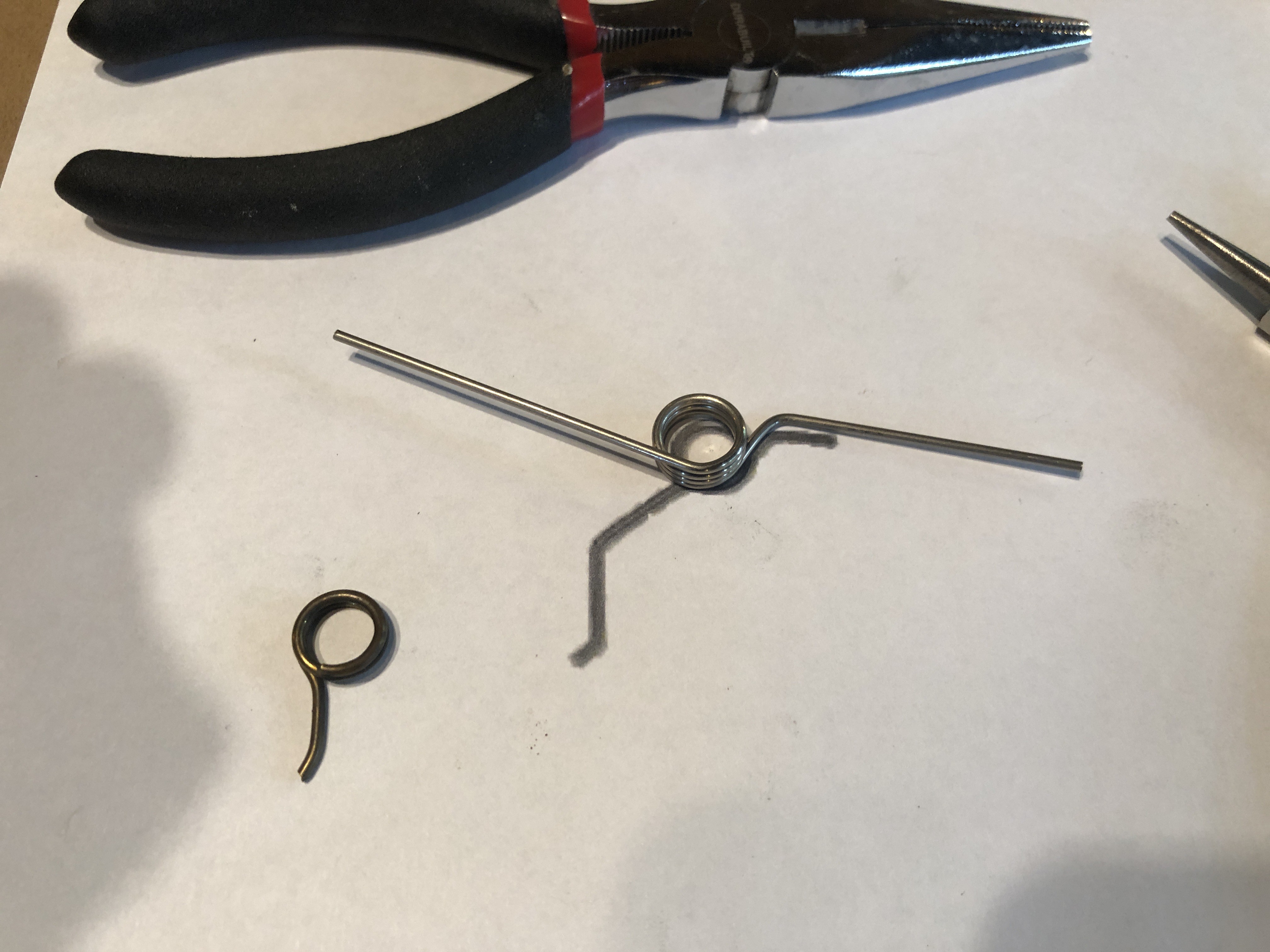

In a previous log, we discovered what was left of a broken spring in the lock. Luckily, I found a post online about my lock with a clear picture of the spring in all its glory.

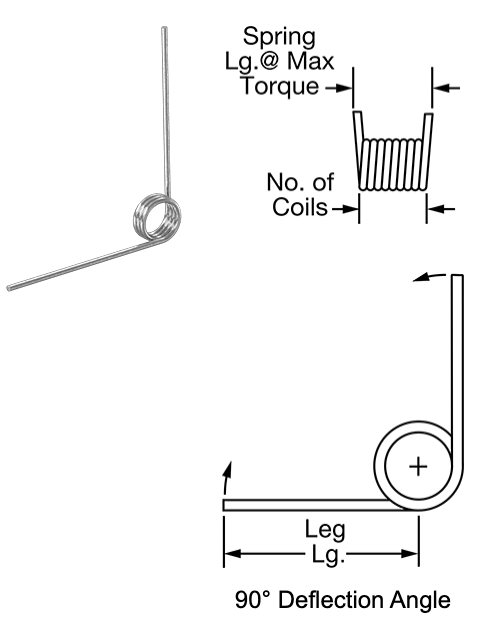

It's not a standard shaped torsion spring, so can't simply buy a replacement.

Making a spring

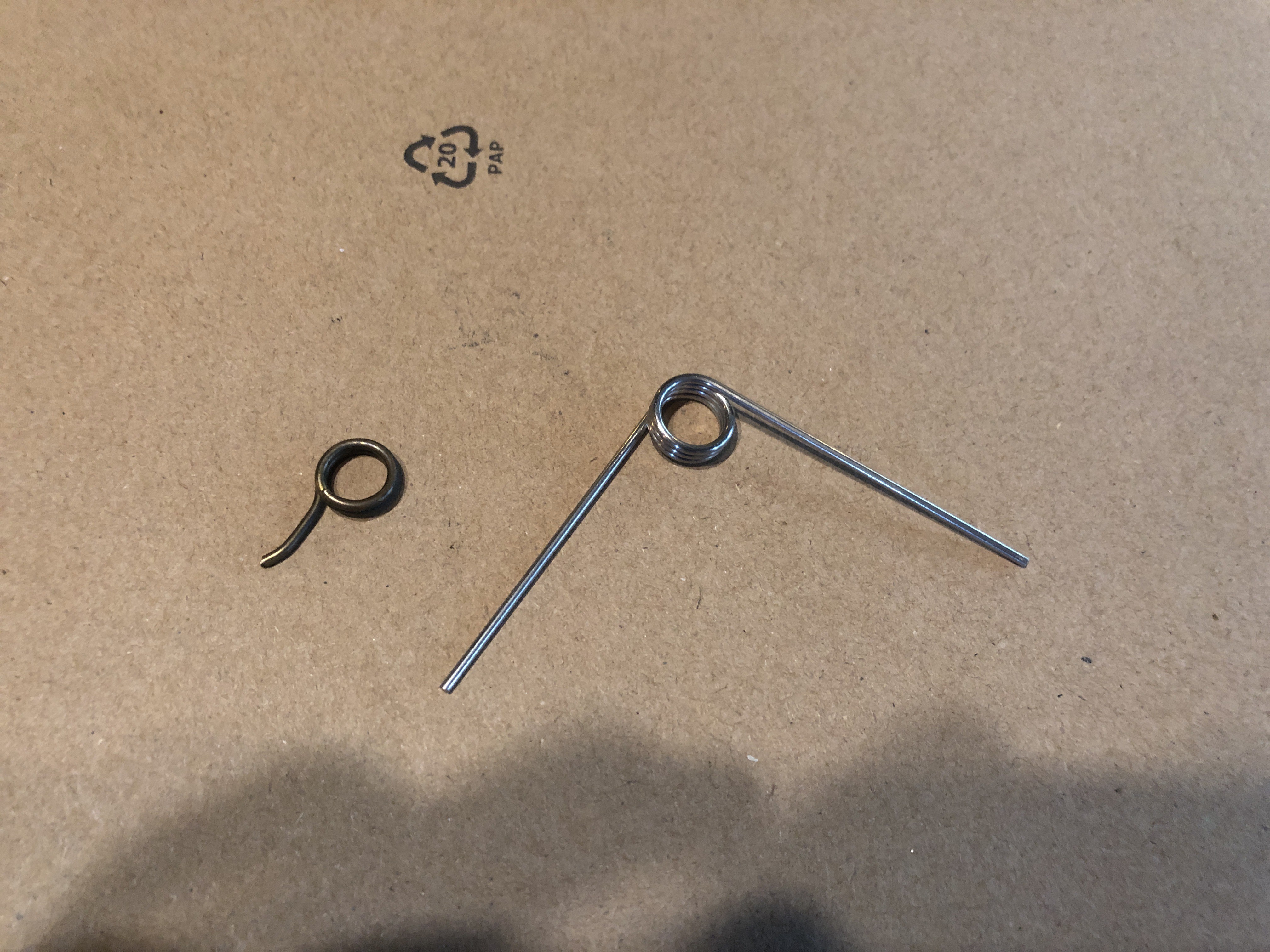

It was clear pretty quickly that I would need to make the replacement spring. I could either buy a whole roll of music wire (spring wire) to make a small spring or buy a similar spring and bend it into shape.

McMaster-Carr to the rescue, as usual. I took measurements of the broken spring -- or what was left of it -- and found that this spring was the closest approximation.

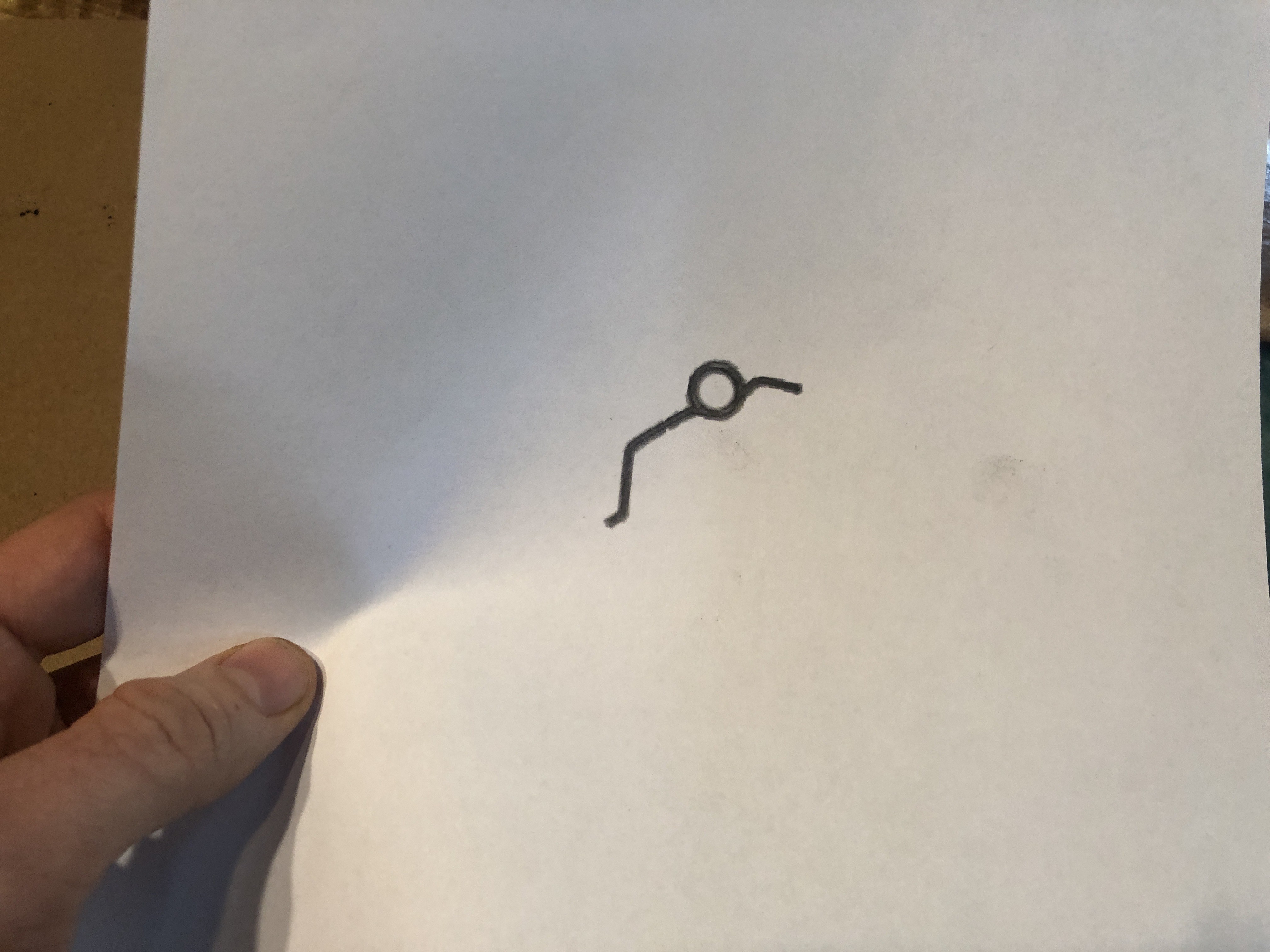

Zoom, Enhance

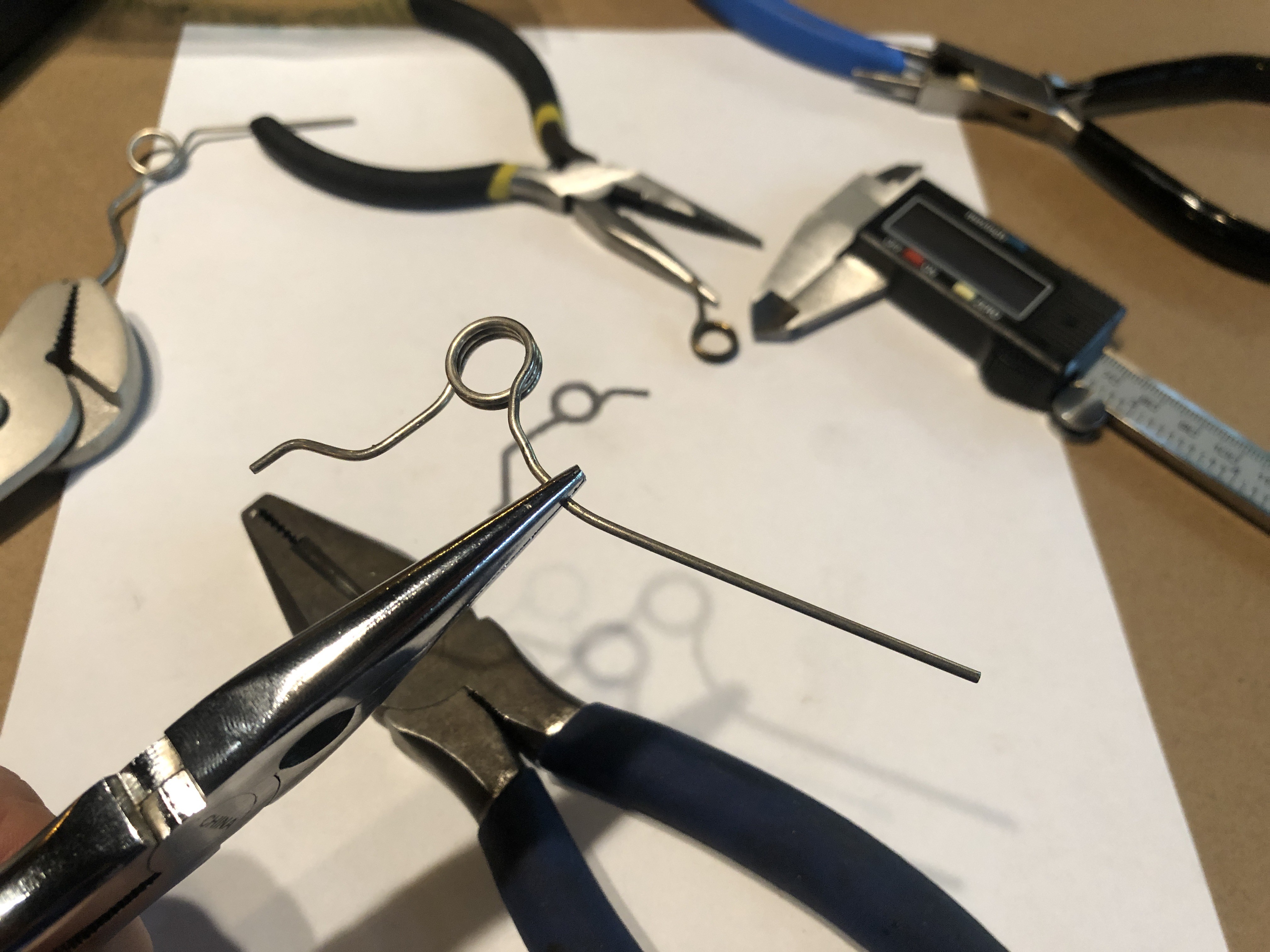

To make this spring as accurate to the original as possible, I'd need to blow the picture up to life-sized. I opened the image in my image editing program (GIMP in my case) and enlarged the picture until the spring windings' outside diameter was the same size as the broken one. Then sent it to the printer.

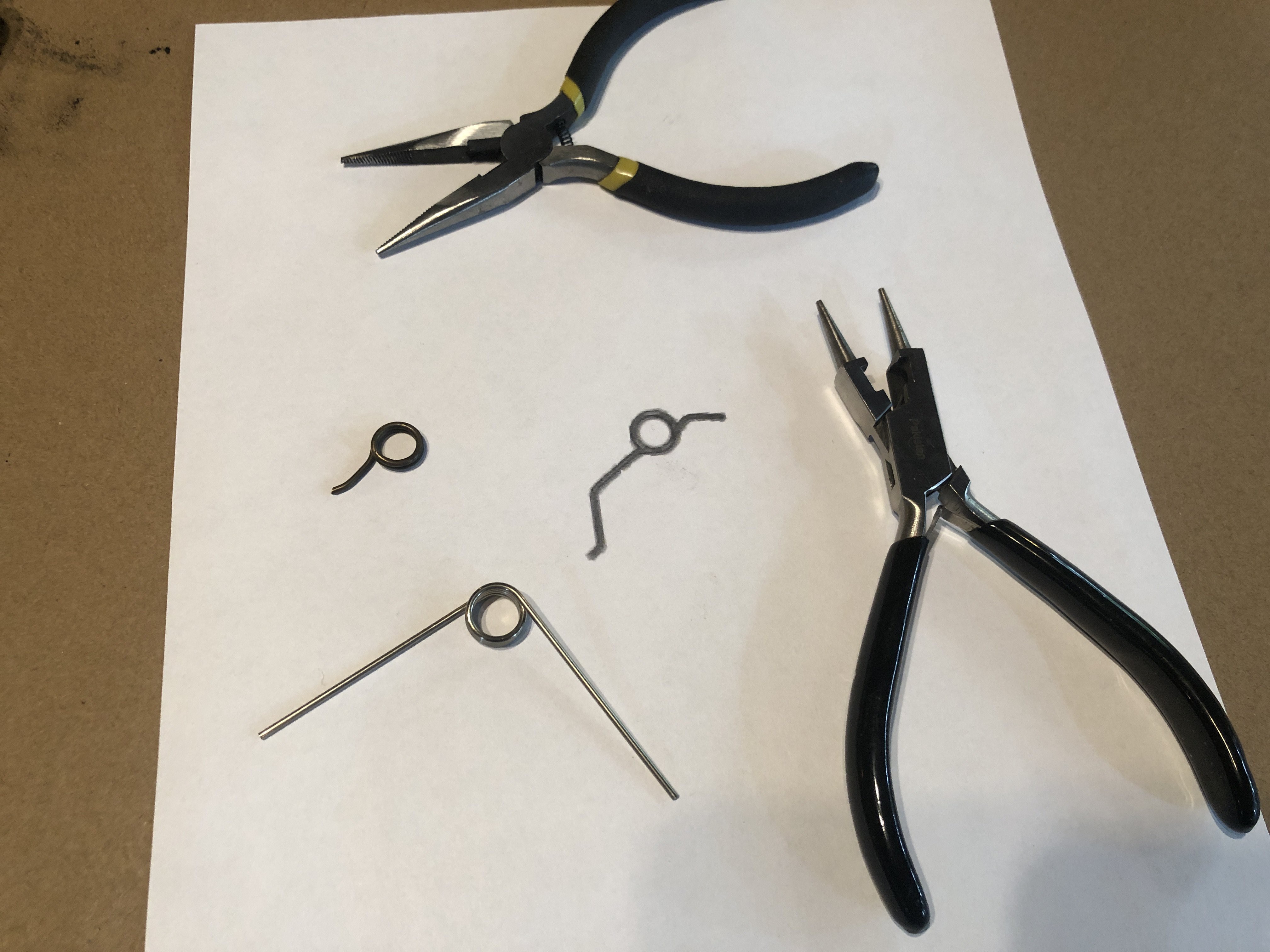

(I ended up trading the round nose pliers for a pair of linesman pliers for the bending)

Bendy

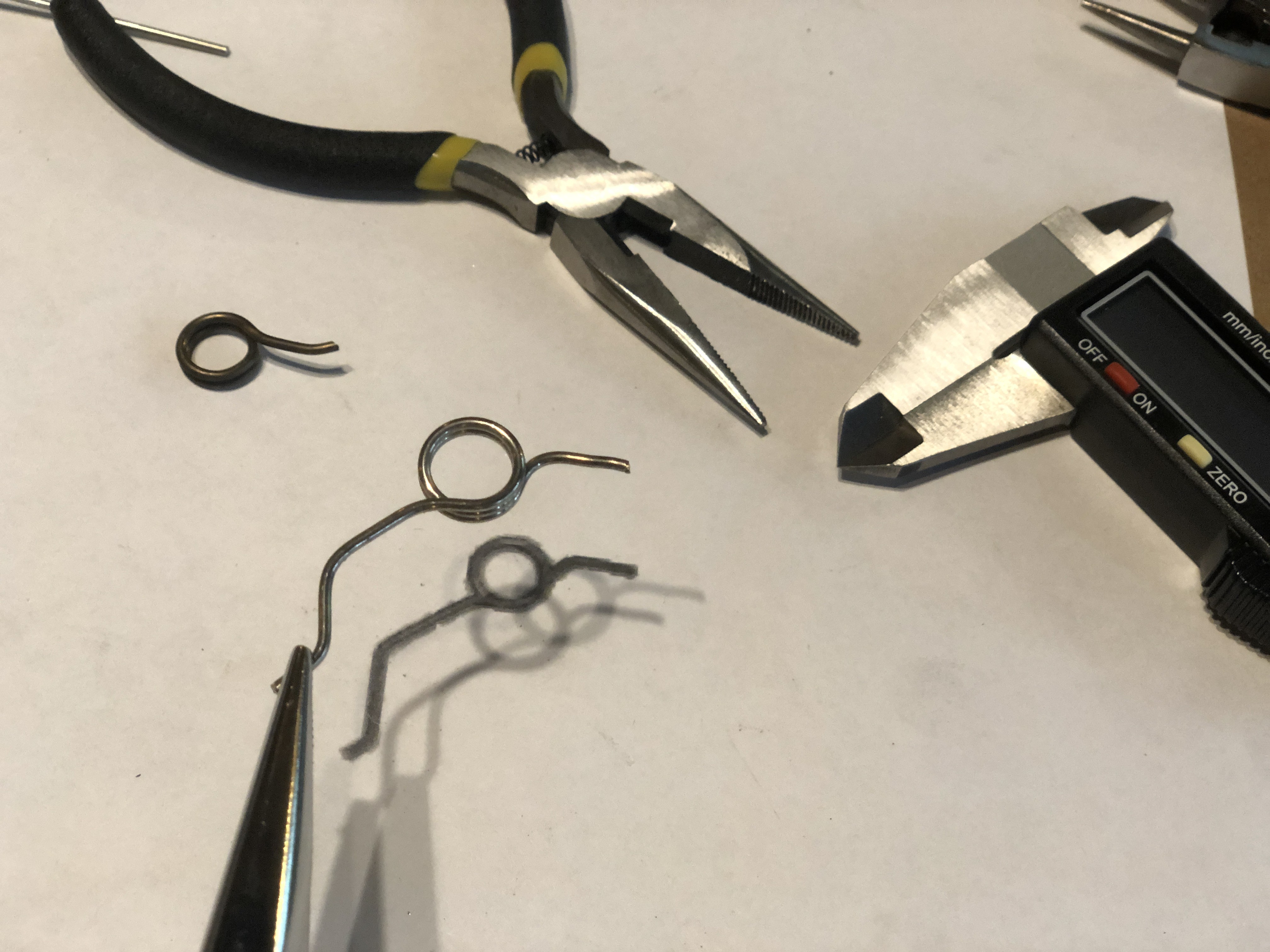

Now, using two pairs of pliers (needle nose and linesman), I carefully bent the legs of the springs to match, using one pair to hold the spring tightly and keep it from deforming and the other to make the bends.

So far so good...

Am I doing this right?

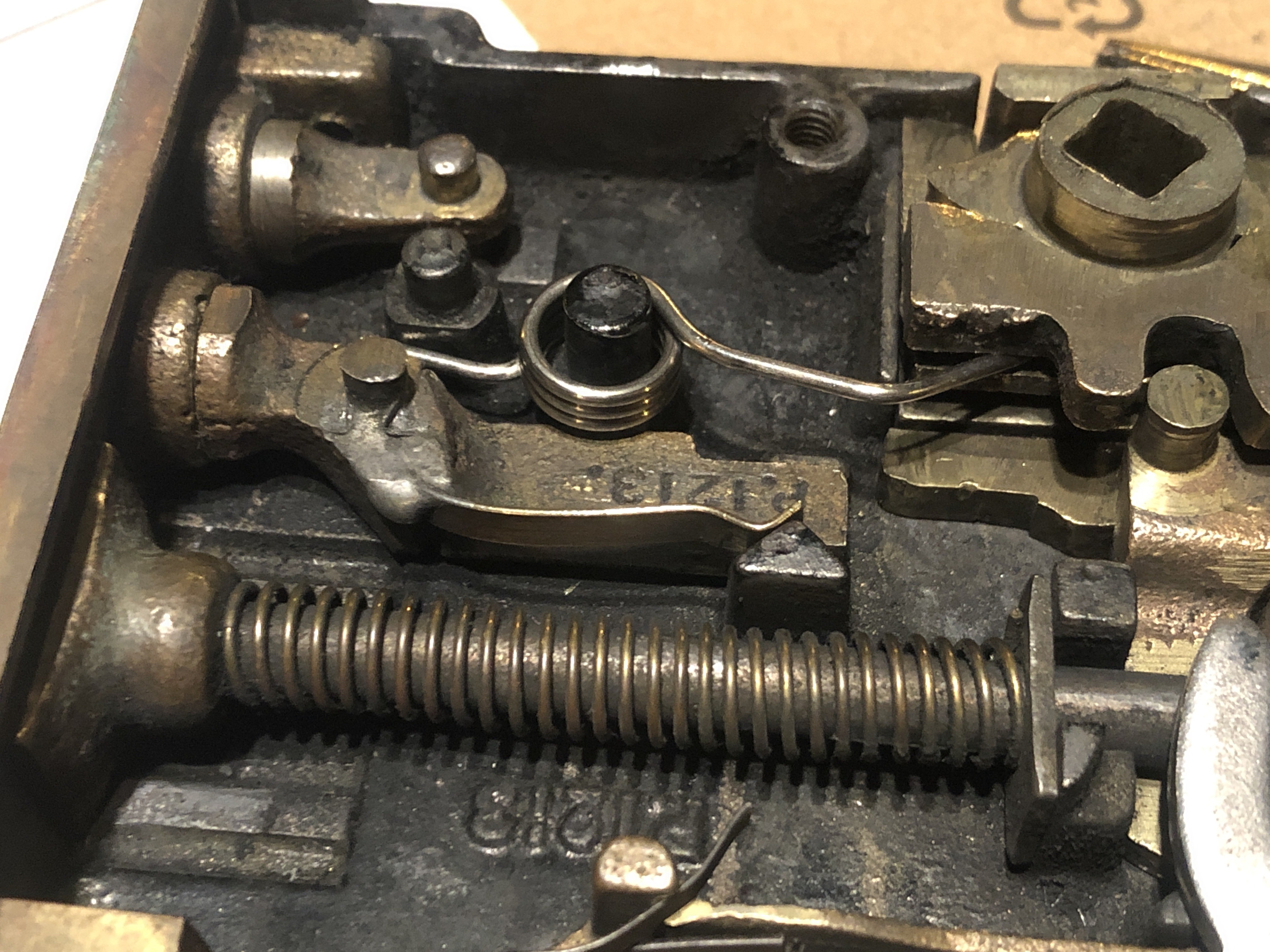

That looks right!

I think we have a match!

I ordered a few extra springs and went through nearly all of them until I was happy with the result.

Are we done?

It felt complete. However, when I put things back together, the latch worked better, but it was still sticking, and the outside lever was still sagging. It was clear there was more to be done.

More investigation was necessary. Stay tuned; in the next log, I'll walk you through what I found.

Jeremy

Jeremy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.