A P100 Mask Intercom

A conventional P100 respirator upgraded for use as COVID-19 PPE by the addition of an intercom and a means of exhaled-air treatment

A conventional P100 respirator upgraded for use as COVID-19 PPE by the addition of an intercom and a means of exhaled-air treatment

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

The tweaking seems to have tapered off into maintenance.

It's looking like I can repair holes in the mask with a tire repair kit, but not the dry-repair kind: tire-repair rubber cement seems to be required (I used "Certified" brand). For intensely curved areas, a piece of black neoprene rubber seems to work as a patch; tire-repair patches are way too stiff for these areas. I just followed the tire repair kit instructions. My source of neoprene membrane was a "Gorilla Grip" glove, model C23403. Use a generous amount of glue. After the repair, consistently performing a suction and pressure test upon donning the mask becomes doubly important. This repair lasted one month in midsummer with frequent outdoor use, then the patch had to be pulled off and replaced. Solar ultraviolet seems to kick hell out of elastomer, some types worse than others. Of course, this summer I am applying sunscreen spray to the mask, so we’ll see how that goes.

Oct. 03, 2022: no deterioration noted, but I did not use the mask much this summer. The sunscreen leaves the mask feeling slimy and it picks up dirt easily. Am looking for a tough UV barrier layer that sprays on and dries non-slimy.

Inspect the mask for damage periodically, with disassembly, to ensure that no unfiltered air is leaking in or out. Places I have found damage: the rim of the funnel and the seals of the inlet filters.

Since the funnel rim was breaking, I reinforced it by hot-gluing it to a sink strainer, as shown below. The parts to be joined were roughened with sandpaper, then cleaned with a paper towel moistened with Varsol. I cut off any glue that extended beyond the strainer to prevent future air leaks.

To replace the P100 component altogether, follow this sequence:

Remove the new exhalation valve protector by prying with a screwdriver.

This will restore basic functionality; the procedure for drilling/punching the sound holes follows.

Summary:

Here is the finished renovation. During final assembly, the filter holder was pared down a bit at the base to provide improved clearance for the earbuds, using an Olfa knife. A new feature was added: a mono mini jack was zip-tied...

Read more »Ensuring a good fit:

In occupational settings, the all-important fit of the mask to the face must be professionally tested before use and every year thereafter. Here is another link re fit testing (both last accessed 02-06-2021). I got my present mask at a hardware store outside of an occupational context but did a DIY fit test with powdered stevia sweetener puffed out of a rubber bulb just after giving the bulb a good shake. The stevia seems to lose its sweetness slowly after removal from the packet, so I grind it fresh for each test. Will try saccharin next. (02-20-2021: saccharin test passed, but self-administered.) NB: I have two years of experience in wearing a respirator occupationally. If you are new to this, you should practice a lot in a safe setting until you know what a good and bad face seal feel like and the moves you need to get a good one.

My big discovery was that moving the mask up or down on my face often did the trick. If that didn't work, the straps were either too loose or too tight. (Tight straps can distort the face seal.) In case of a seal problem, let the mask warm up on your face for five minutes before trying any adjustments.

I learned how to wear a respirator in a paint shop where there are smelly fumes that you can smell if they leak into your mask. This facilitated the learning process and I am not surprised that OSHA provides a smell option for fit testing involving water solutions of isoamyl acetate; using smell is so much more convenient than taste (no need for a "nebulizer" that often blocks up) and makes a more stringent and foolproof test because to pass, the mask has to keep out individual molecules, which are vastly smaller than the tiniest particles of concern in infection control. You just swap organic vapor cartridges for filter cartridges for the duration of the test, then swap 'em back afterward.

In cold weather, a mask leak can fog up my glasses and thus be detected easily if it occurs alongside my nose, which is a problematic area anyway. Fogged glasses can be good for detecting leaks.

11-18-2021: FYI

At the start of the project, I had 3 identical P100s, all bought before the pandemic. They cost the equivalent of $47 US apiece in Ontario in the fall of 2019.

The microphone is a repurposed pair of earbuds. Not only can earbuds convert electrical oscillations into sound, but they can do the reverse as well. The ring and tip poles were jumpered together inside the intercom box to provide redundancy; if one earbud fails, you can continue to communicate through the other. The final hole size in the hard nylon insert was 1/4" dia, unlike what the first picture shows (11/64"). The eartips were removed from the earbuds and the necks were forced through narrow holes in the elastomer part that had been made with an 11/64" drill bit, but a leather punch is now preferred. The holes in the nylon part were enlarged to 1/4" to make room for the part of the neck that protruded inside.

When drilling the hard nylon, insert an aluminum plate between the nylon and elastomer parts to prevent the drill bit from lunging forward into the elastomer. Don't leave any turnings between the rubber and nylon parts. Use a leather punch on the elastomer and not the pliers kind, which won’t reach without distorting the workpiece. One-eighth inch diameter is too small but 1/4” diameter will be too big.

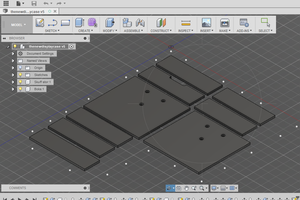

The following is a chronological series of pictures meant to compliment the circuit diagram and parts list.

A problem with the P100 is that there is no filtration on the exhalation valve, so others are not protected if the wearer is infected by SARS-CoV-2 in spite of taking unusual precautions. I therefore connected a fabric filter holder to the exhalation valve, which prevents all exhaled-air leaks when a standard, blue medical mask is mounted on it.

Making a fabric filter holder: I first prepared a 6-cm dia. plastic kitchen funnel by sanding the places where future hot glue would go. I then cleaned off the sandings. I cut off the hanger tab and then encircled the funnel with a bead of glue to help hold the fabric filter. I then cut off the original funnel stem and drilled small holes near the bottom to pass the hold-down wire. I then assembled a flared tube on the mask and used hot glue to seal the seam between the funnel and a new, larger stem tube placed below it. The bottom seam was also sealed with hot glue after the pictures below were taken, also with prior roughening and cleaning. The stem tube was cut from a 1.5" dia. aspirin bottle along the top and bottom of the label. The label was then scraped off near the bottom to allow a fit to the exhalation valve.

The hold-down wire is 20-gauge, tin-plated copper (header wire). The wire is U-shaped but with a flat bottom of the "U." It passes under the existing exhalation-valve protector before going up and passing through small holes inside the filter holder, after which it is folded down on each side, with tensioning, and glued. Holes were drilled with a 3/64" twist drill.

The stem tube fits snugly into the exhalation valve protector on the mask without leaks, but getting it to go in required a combination of force, accurate alignment, and stuffing in the parts that boinked out. A lubricant might have helped; haven't tried it. Something else to try would be filing the end of the tube on a bevel.

The fabric filter should be stretched over the funnel, pulled down around the edges, and cinched into place with a hair elastic; the elastic stays trapped between the rim and the glue bead. The mounting operation takes a bit of practice, and I evolved the following method: Hold the pulled-down filter in your fist so there is a space between your hand and the rim where a portion of the elastic can sit securely while you stretch it over the rest of the filter. Then go around the rim gently pulling out wrinkles

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Timescale

Timescale

Øystein

Øystein

2FTG

2FTG