Ensuring a good fit:

In occupational settings, the all-important fit of the mask to the face must be professionally tested before use and every year thereafter. Here is another link re fit testing (both last accessed 02-06-2021). I got my present mask at a hardware store outside of an occupational context but did a DIY fit test with powdered stevia sweetener puffed out of a rubber bulb just after giving the bulb a good shake. The stevia seems to lose its sweetness slowly after removal from the packet, so I grind it fresh for each test. Will try saccharin next. (02-20-2021: saccharin test passed, but self-administered.) NB: I have two years of experience in wearing a respirator occupationally. If you are new to this, you should practice a lot in a safe setting until you know what a good and bad face seal feel like and the moves you need to get a good one.

My big discovery was that moving the mask up or down on my face often did the trick. If that didn't work, the straps were either too loose or too tight. (Tight straps can distort the face seal.) In case of a seal problem, let the mask warm up on your face for five minutes before trying any adjustments.

I learned how to wear a respirator in a paint shop where there are smelly fumes that you can smell if they leak into your mask. This facilitated the learning process and I am not surprised that OSHA provides a smell option for fit testing involving water solutions of isoamyl acetate; using smell is so much more convenient than taste (no need for a "nebulizer" that often blocks up) and makes a more stringent and foolproof test because to pass, the mask has to keep out individual molecules, which are vastly smaller than the tiniest particles of concern in infection control. You just swap organic vapor cartridges for filter cartridges for the duration of the test, then swap 'em back afterward.

In cold weather, a mask leak can fog up my glasses and thus be detected easily if it occurs alongside my nose, which is a problematic area anyway. Fogged glasses can be good for detecting leaks.

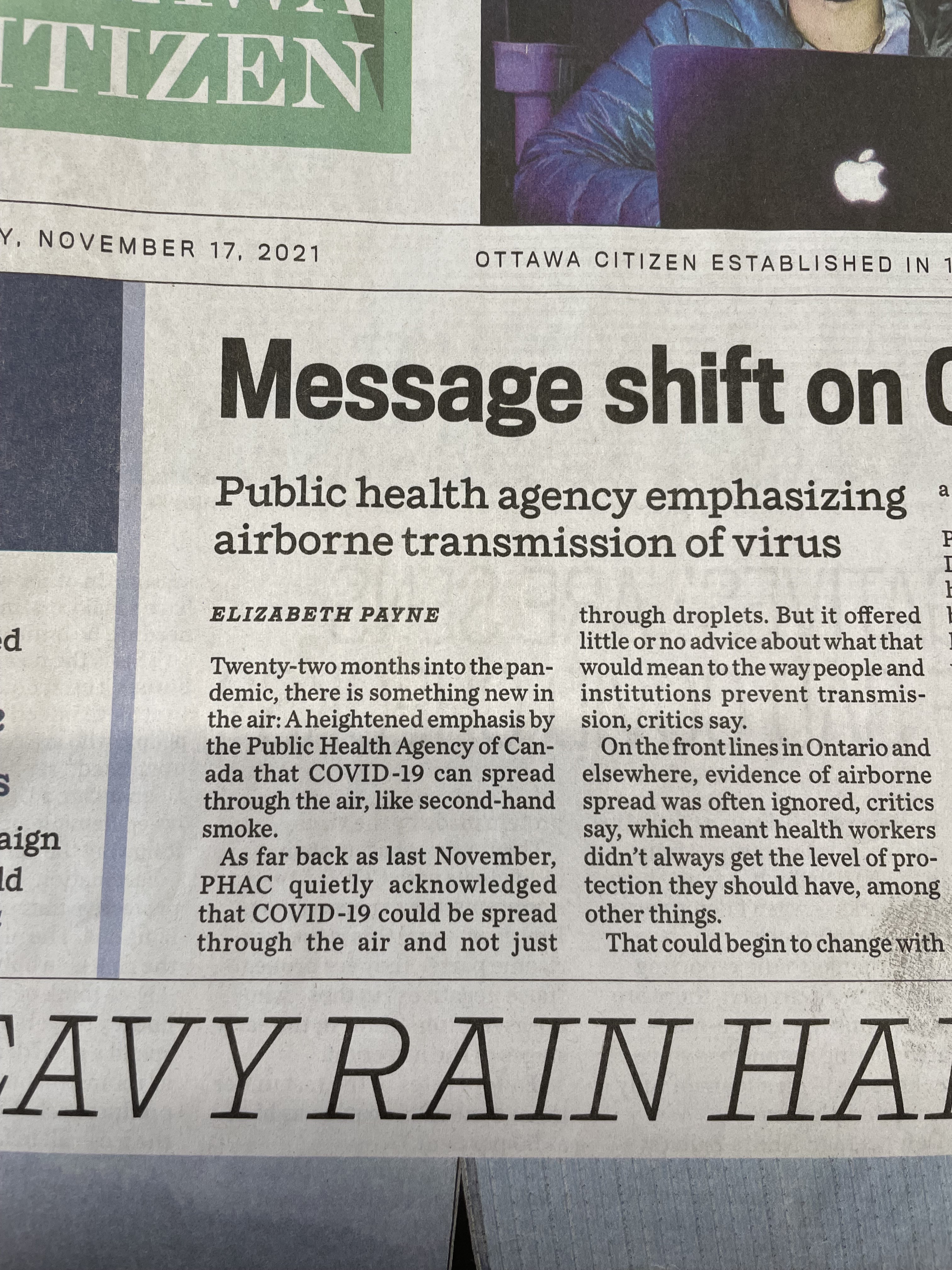

11-18-2021: FYI

David Matthew Mooney

David Matthew Mooney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.