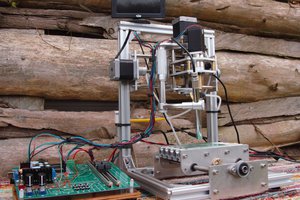

Overview of Machine

Front View

- Power indicator

- X-axis motor

- DC Spindle Motor / Plotter

- Working Depth Limiter

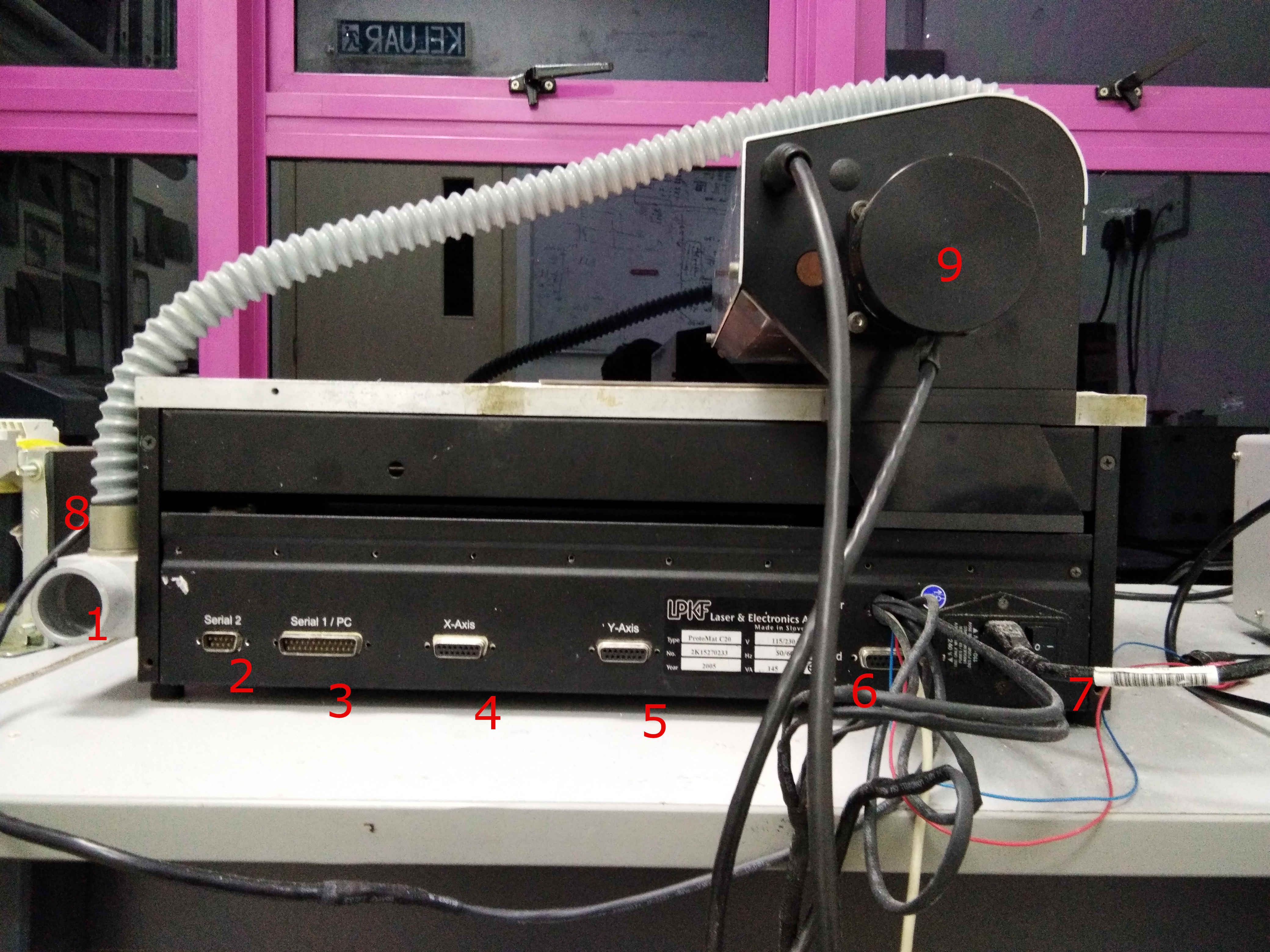

Rear View

- Vacuum System Connection

- Serial port (9-pin) for expansion units

- Serial port (25-pin) for connection to PC

- X Motor Connection

- Y Motor Connection

- Connection for plotter head

- ON/OFF switch with mains connector and fuses

- X Motor

- Y Motor

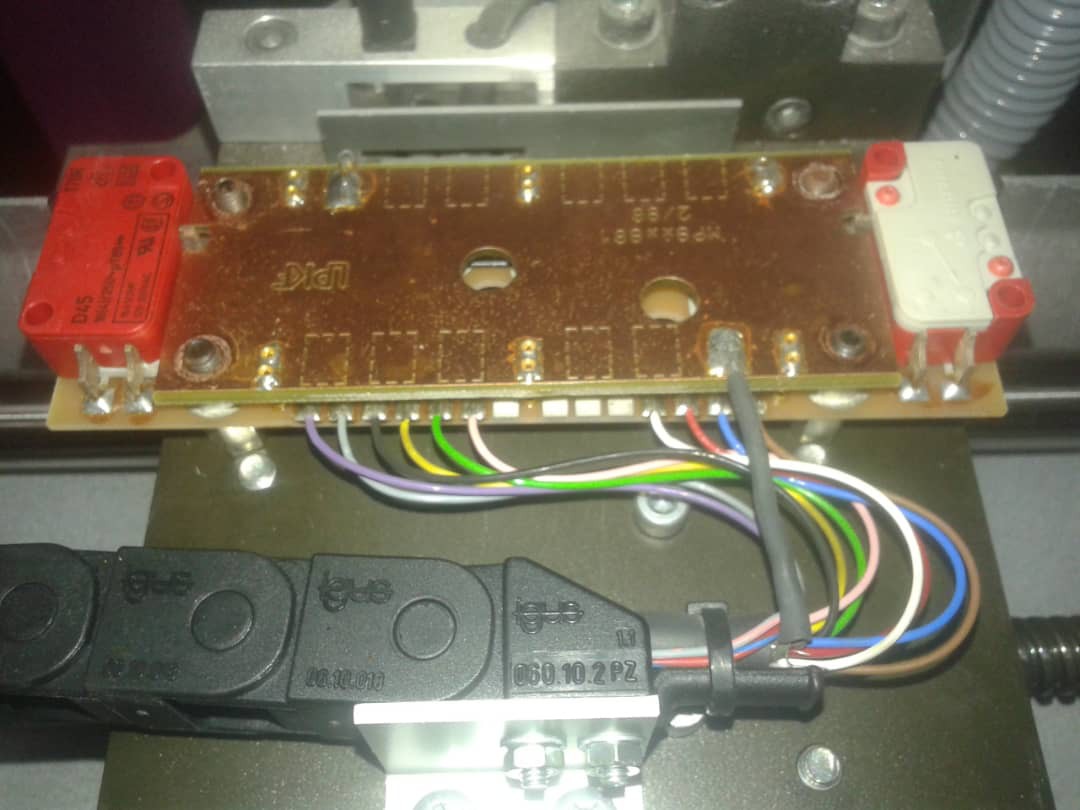

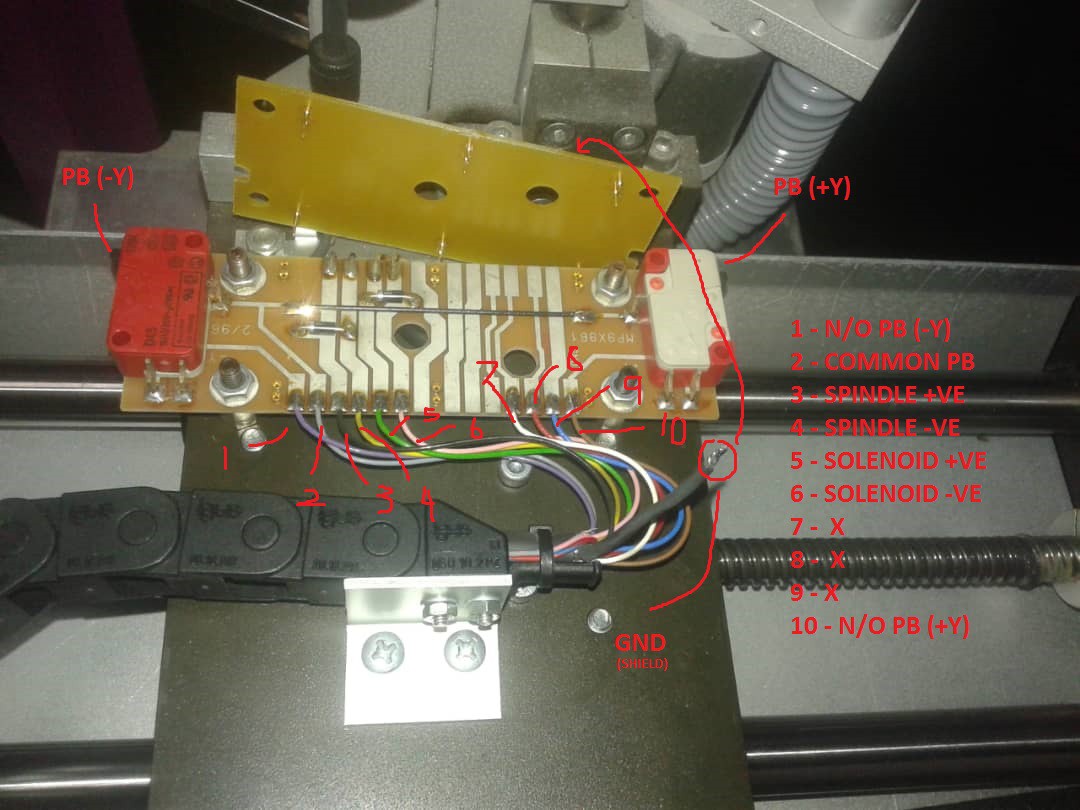

Plotter Board

- Normally Open Limit Switches for – Y axis

- Common terminal for Limit Switches

- Spindle / Plotter +DC Supply

- Spindle / Plotter –DC Supply

- Solenoid Actuator +DC Supply

- Solenoid Actuator –DC Supply

- NC

- NC

- NC

- Normally Open Limit Switches for +Y Axis

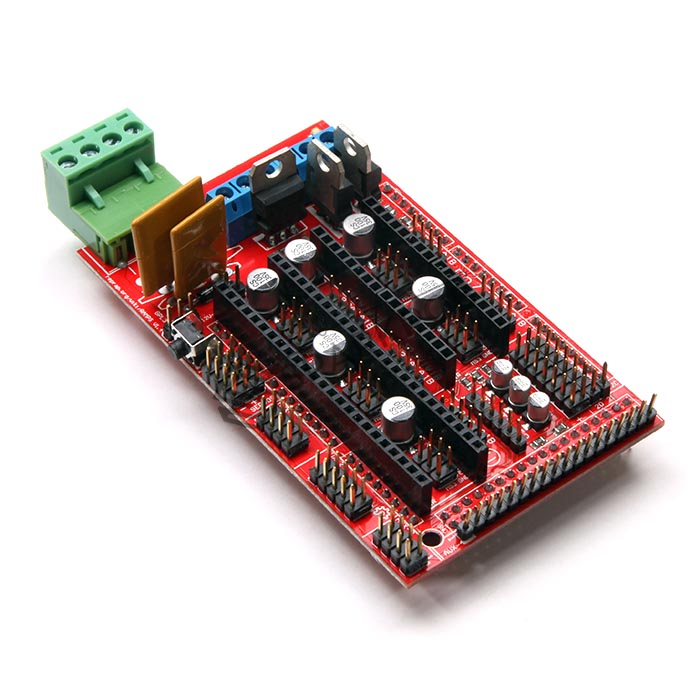

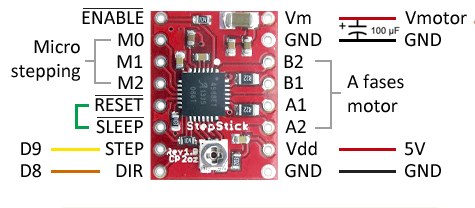

Controller Board

- Mains EMI Filter

- Transformer

- Rectifier (GBU4D) 34V DC Output

- Rectifier (GBU4D) 78V DC Output

- Rectifier (GBU4D) 11V Dc Output

- Processing Unit

- Stepper Motor Controller (L6203) DMOS Full Bridge Driver

- Stepper Motor Controller (L6203) DMOS Full Bridge Driver

- Plotter Head Controller

Plotter / Spindle Head

- Shock Absorber

- Solenoid

- Working Depth Limiter

- Tool Changer Handle

- Mounting for Spindle

- DC Spindle Motor

- Vacuum Connector

himynameisNaim

himynameisNaim

joekutz

joekutz

DIY GUY Chris

DIY GUY Chris

Martino Ferrari

Martino Ferrari

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠