"Something" to be found in these logs:

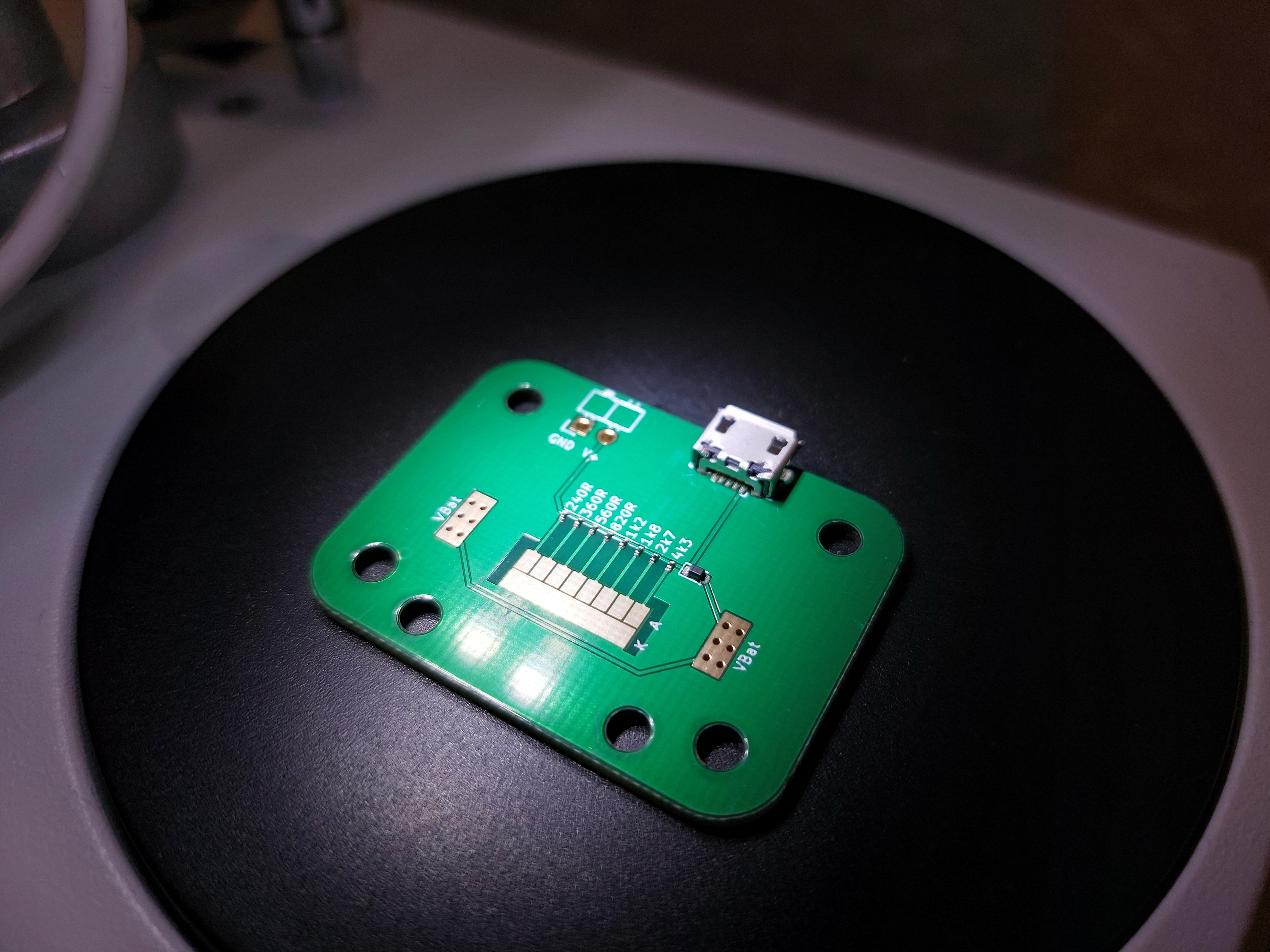

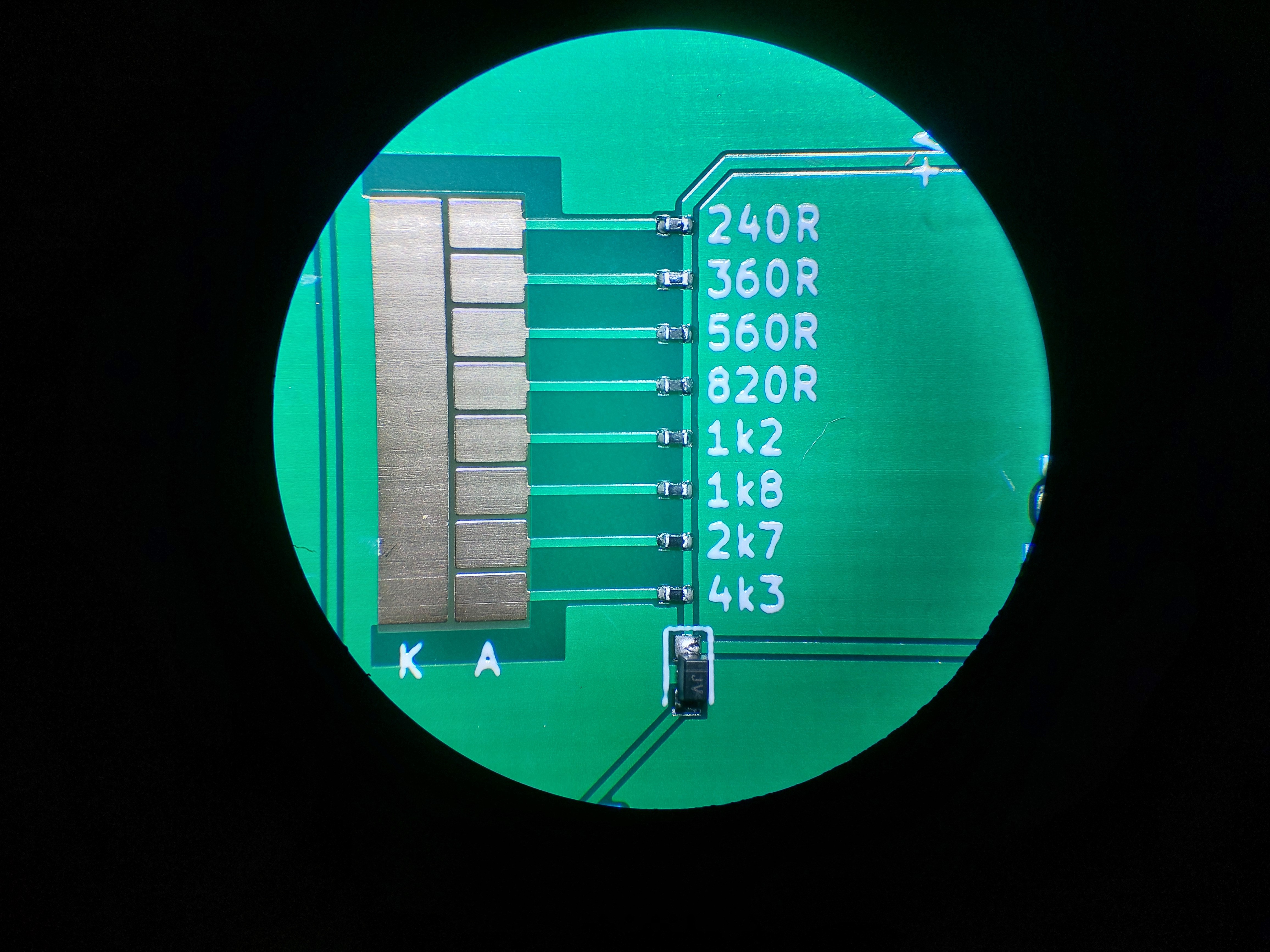

- Nr. 1 (pictures! and how it's used)

- About the stencil jig

- Nr. 4 (had to add paste for one resistor that didn't get any paste at all)

- Nr. 7 (major breakthrough!!!)

- Nr. 12 (some problems here!)

- Nr. 19 (paste was a bit runny on the 360 Ohm resistor)

- First results after 19 boards

Full TOC:

- Nr. 1 (pictures! and how it's used)

- About the stencil jig

- Nr. 2

- Nr. 3

- Nr. 4 (had to add paste for one resistor that didn't get any paste at all)

- Nr. 5

- Nr. 6

- Nr. 7 (major breakthrough!!!)

- Nr. 8 (swapped two resistors, had to rework)

- Nr. 9 (slightly bad paste job)

- Nr. 10

- Nr. 11

- Nr. 12 (some problems here!)

- Nr. 13

- Nr. 14

- Nr. 15

- Nr. 16

- Nr. 17

- Nr. 18

- Nr. 19 (paste was a bit runny on the 360 Ohm resistor)

- First results after 19 boards

- Nr. 20

- Nr. 21

- Nr. 22

- Nr. 23

- Nr. 24

- Nr. 25

- Nr. 26 (some pictures!)

- Nr. 27

- Nr. 28

- Nr. 29

- Nr. 30

- Nr. 31

- Nr. 32

- Nr. 33 (picture)

- Nr. 34

- Nr. 35

- Nr. 36

- Nr. 37

- Nr. 38

- Nr. 39 (one short on the USB connector)

- Nr. 40 (pictures!)

- Nr. 41

- Nr. 42

- Nr. 43

- Nr. 44

- Nr. 45

- Nr. 46

Christoph

Christoph

zakqwy

zakqwy

Jarrett

Jarrett

leo60228

leo60228

2bluesc

2bluesc

Your project got mentioned in the Macrofab Engineering Podcast #331. They took it almost serious, made me smile.

https://macrofab.com/blog/mep-ep331-the-pcb-plague/