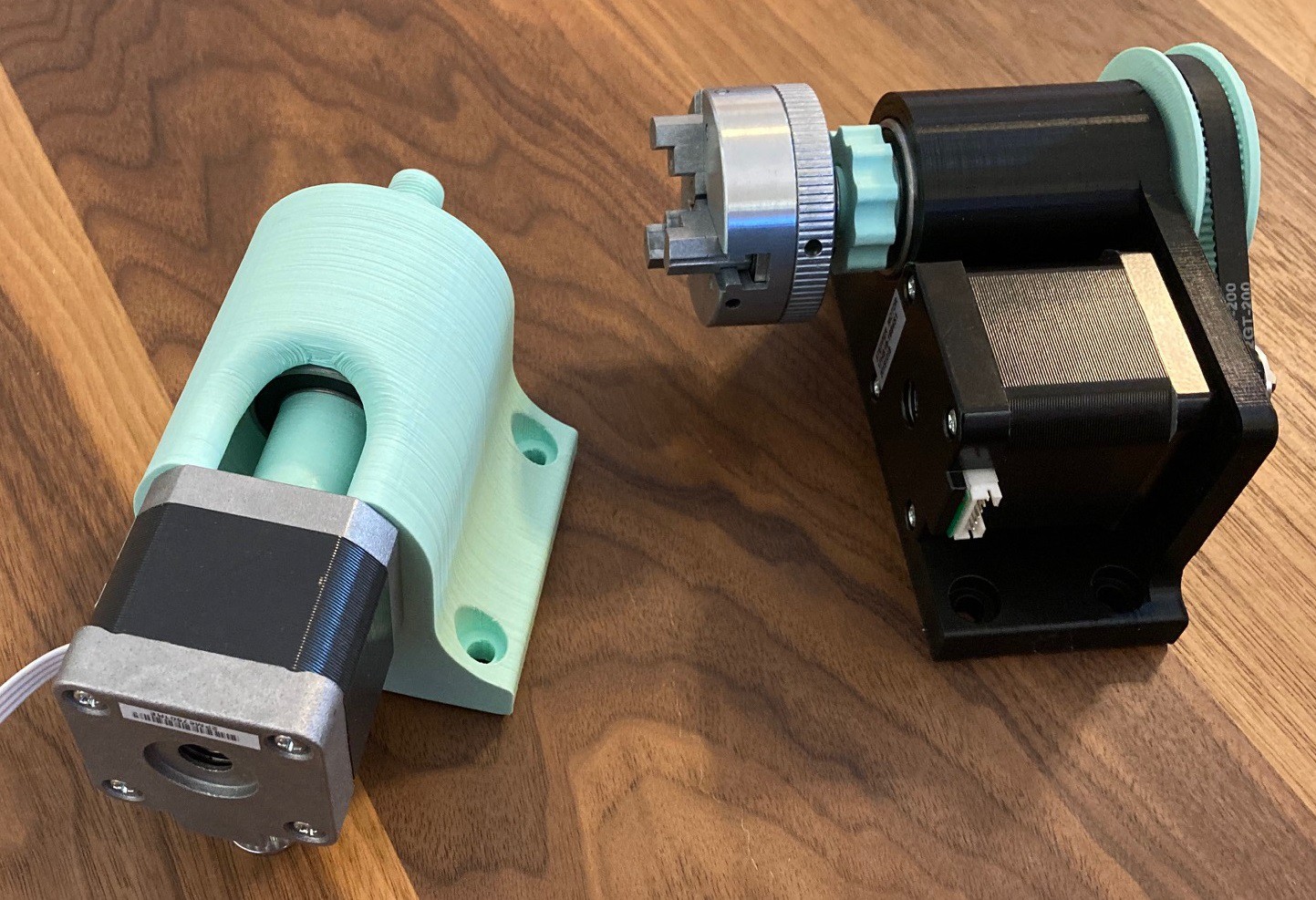

I finally took my rotary axis(s) for a spin and both of them seem to work great. The direct drive axis lacks power, I can easily stall out the motor with only a minor amount of pressure on the spindle. Coupled with its lower resolution I don't recommend using it. It does save a tiny bit on filament and does not need a belt, but the belt drive just works better.

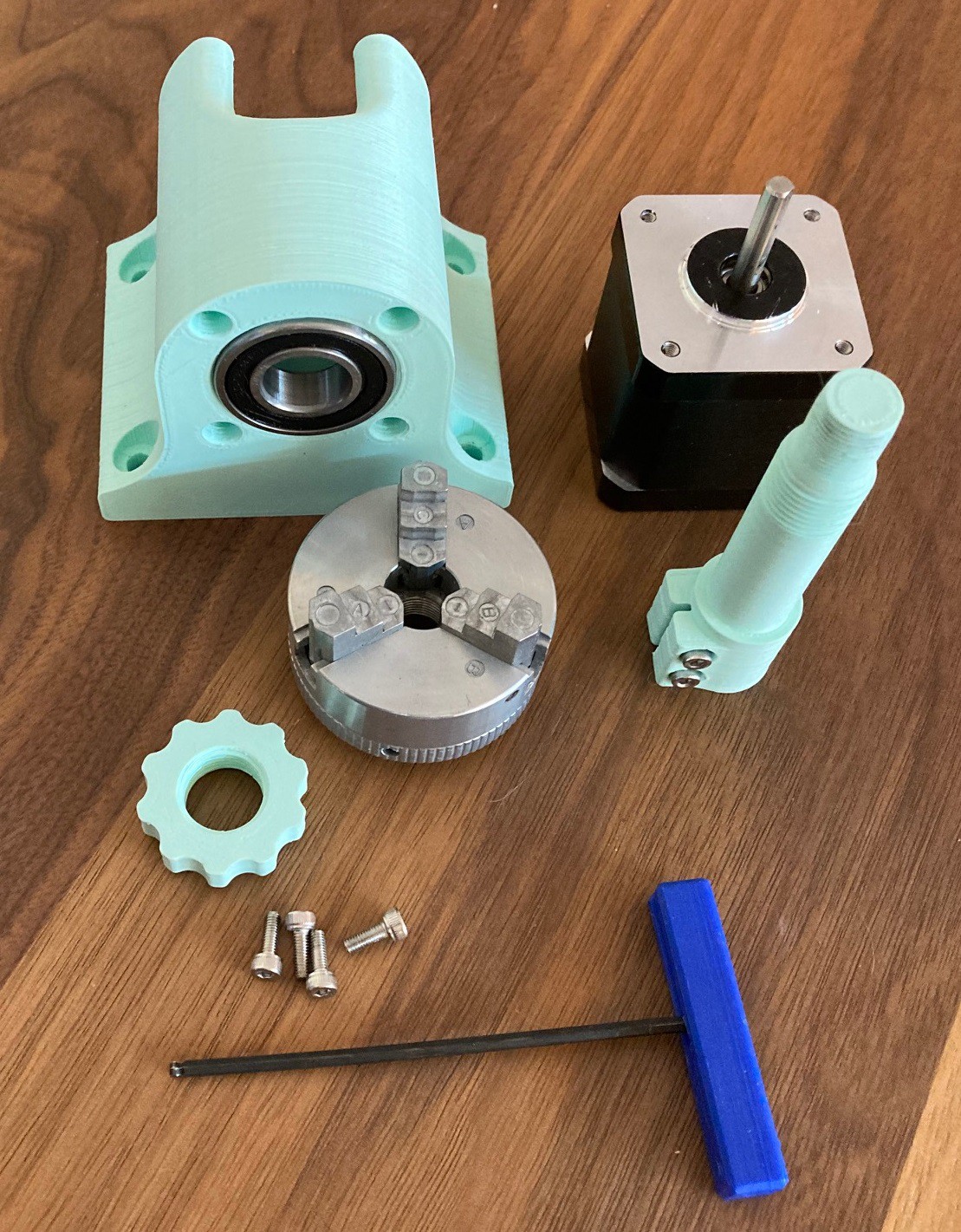

Here is a comparison of the parts between each. It really comes down to a 200 mm belt and an extra pulley and screw.

So my system uses dual y-axis drivers with independent control during homing all running on a GRBL shield on an UNO. That leaves me with no spare drivers to run the rotary. Because there are dual Y axis and I don't want to loose z control I am swapping the rotary with the x axis for now. This works ok, but it has a few problems.

First the x axis is now just floating, that makes it nearly impossible to do any sort of milling without mechanically blocking the x axis up. It also prevents us from doing a true 4 axis mill with the x axis being free to move side to side. LightBurn can only work in rotary mode with the rotary on the y, z, or a axis, it does not support x (why I don't know, or understand). To work with LightBurn then we have to pretend the x axis is not a rotary and do all the image scaling by hand to make it wrap properly onto the material without distortion.

The math is not too hard. For my belt drive unit the stepper motor has 200 steps per revolution, with the 3:1 gear reduction that goes up to 600 steps/revolution and with 1/16 micro stepping enabled that goes up to 9,600 steps per revolution, or 26.67 steps per degree. My x axis was already setup to 400 steps per mm, so doing a bit of math we get 24 mm of x axis motion in LightBurn equal to one revolution.

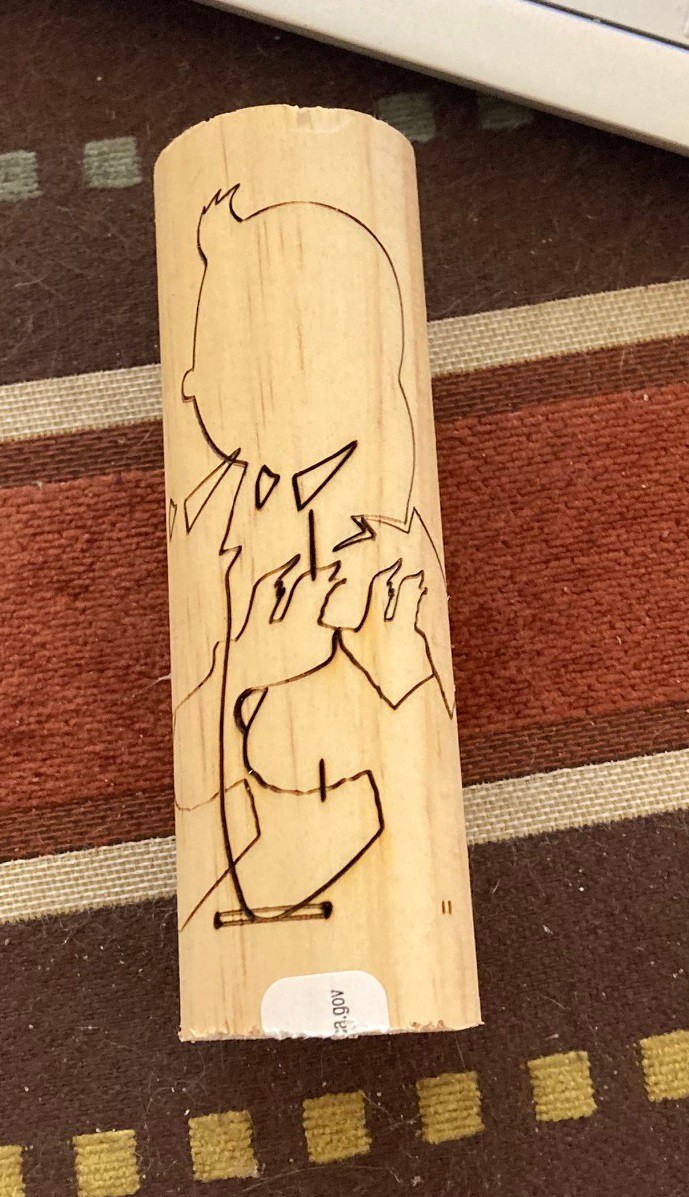

In order to make sure the image on our cylinder does not end up with any distortion we have to do a bit of math and rescale the x axis of the image. In my case I have a 31.8 mm diameter dowel, multiplying by 3.14 gives me a circumference of 100 mm. Since 1 revolution equals 24 mm on our controller we then need to rescale all our images by 0.24 (24%) in the x direction.

In your editing program you would then create an image 100 mm wide and however tall you want the pattern to be. Once you import it into LightBurn you would rescale the x axis by 24%, being sure to unlock the x and y axis so we don't rescale the whole image.

It is a bit hard to tell here, because I burned over the same spot more than once on previous tries, but the left facing tin-tin is scaled properly. My focus was set a bit high because the base of the laser was interfering with the rotary chuck. That has made the non square nature of this laser even more easy to see. I suspect the small diameter of the stock also played a role, and it is possible that I did not have my laser focused exactly over the center of the axis of rotation.

The big question is, is this worth while? I think as long as there are not enough axis available on the controller this becomes a difficult thing to recommend. There is just too much math involved and it is too tricky to make it all work. I have a few 5 axis controllers on order and we will see how they work once they get here from China. In the meantime I will keep experimenting, but I hope it works out well in the end once it can be built more permanently into the machine.

I still need to come up with some way to support the other end of the workpiece, probably with some sort of a live center. And I would really like to get rid of the 2" metal chuck and go with an all 3D printed chuck, and/or other adapters that can be easily swapped out. I would keep this chuck but it relies on a very fine pitch thread that is not really a good fit for any future chucks, I would much rather rely on a more robust thread or some other hold down mechanism.

Also the bearings I'm using have a lot of resistance, and that is made much worse when I tighten the nut on the shaft down snug. I need to put some sort of a standoff between the bearings that I can tighten everything down against, and ideally I would clean out the bearings as well, they feel like they are packed with grease and that is probably cutting down on some of my stepper motor torque.

---

I put up plans for my belt drive rotary on thingiverse.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.