Posts have been slow recently, but not for a lack of trying. I have been pulling many different GRB and Marlin variants out and trying them on my new MKS Gen L v2.1 hardware, but so far each has its downside.

- Marlin 2.0 looks great on paper, but it does not seem to be well supported by gcode senders commonly used with CNC machines. It also does not have a lot of dedicated CNC support, for example the asci displays seem to be heavily geared towards 3D printers with no options to repurpose it.

- GRBL has no support for a 4th or 5th axis and does not support any other board than the uno and cnc shield. This is frustrating, they could have easily added support for all the 8 bit 3D printer boards out there. It also has no support for displays or SD cards so there is no simple way for offline control of the machine. GRBL also has no support for serial control over the stepper drivers so you can't use stall detection or higher resolution micro stepping.

- GRBL-MEGA is not in active development and does not support auto squaring of the Y axis when using two motors. It is several revisions behind GRBL and has nothing to offer us other than it works on a Mega (ramps) board. This should be merged into the base GRBL project, but sadly it is not.

- GRBL-MEGA-5X does have auto squaring support, although it is not well configured out of the box. I had to reorganize some of the endstop pins to make it use the Y endstops properly. I do have it up and running and it should be as capable as stock GRBL on a UNO board. Unfortunately we still don't get the display or sd card support but we should be able to still use the laser and have touch probe support.

- There are other firmwares out there as well but they seem to either not support older hardware (32 bit) or they are not well maintained anymore.

I finally got it all running on grbl-mega-5x, and I have a roughly stubbed in version on Marlin 2.x however I have yet to find a sender that works with it. My hope is to finish polishing up grbl and making a writeup on getting it running on the MKS Gen L 2.1 board (or any ramps board).

---

My order for a MKS Robin Nano v2 board got canceled, probably from a lack of supply. I'm still contemplating ordering a 32 bit board, but for now there is nothing out there that I can get for a reasonable price that looks interesting to me.

However I am very interesting in the MKS TFT24 or TFT32 touchscreen to be used as an offline controller. MKS has a CNC project that can run on the display and that can take over control of the machine via serial port. The price is right at around $25 for the display, however the larger (and higher resolution) TFT32 display is really hard to find right now.

There are several other offline controllers out there that also deserve inspection, including running octoprint on an arduino. I need to spend some more time investigating this before pulling the trigger.

https://github.com/makerbase-mks/MKS-TFT

---

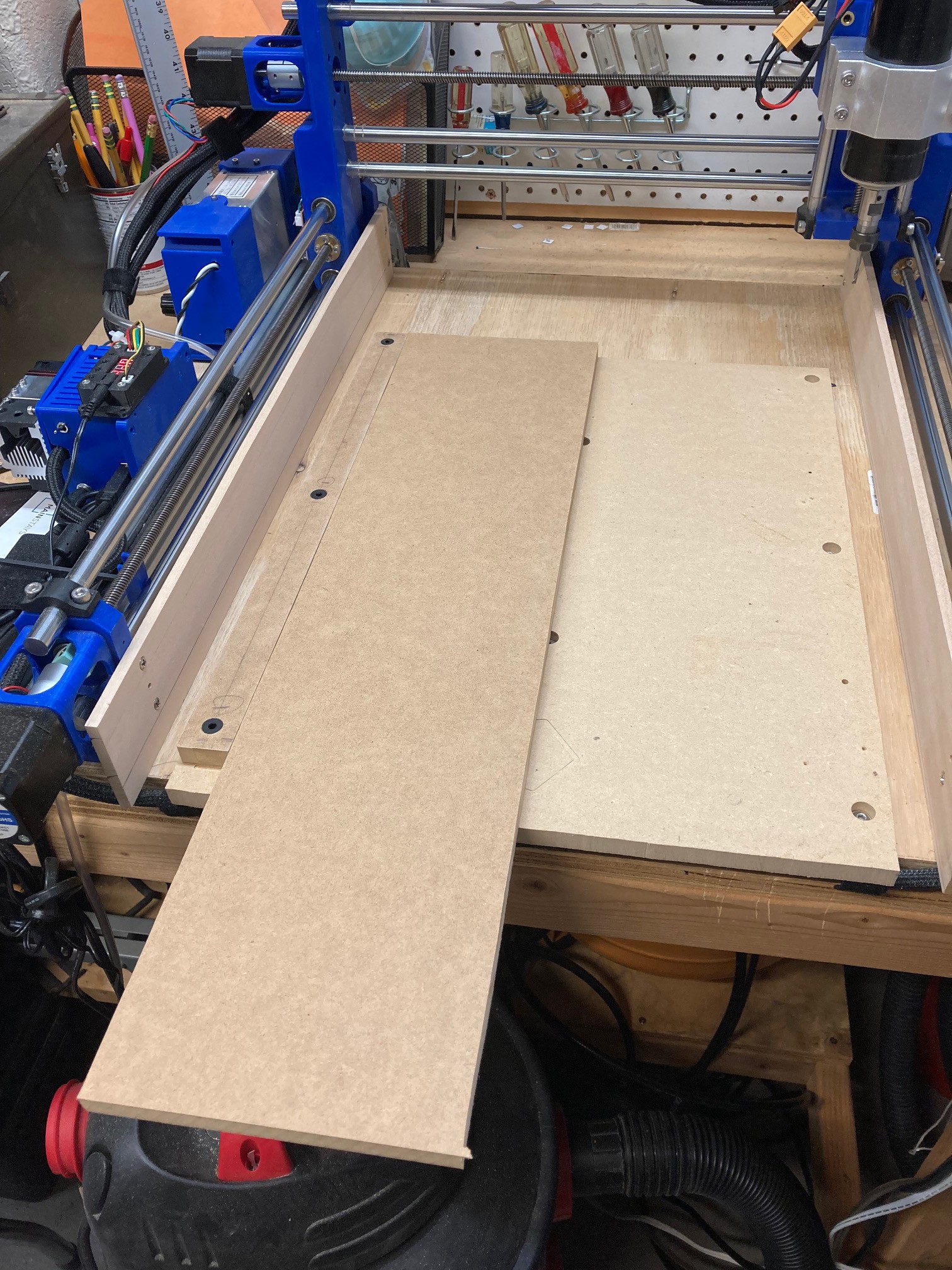

I was able to cut out a guide for my table to help when tiling cuts. I cut 3 holes in a strip of wood and then used 3D printed plugs that use a friction fit into the board and line up with the recessed holes already cut in the spoiler board for holding it to the bed.

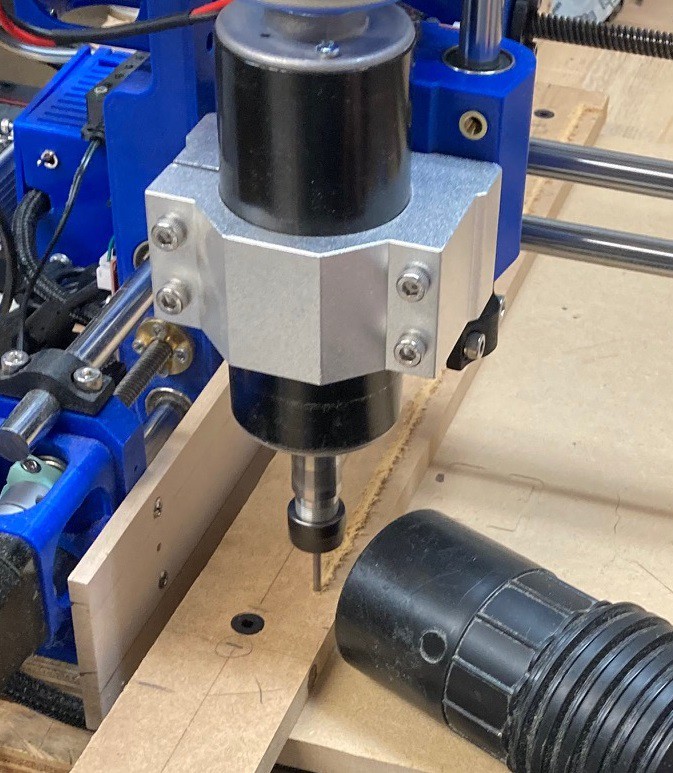

Here I am cutting the face of the board square to the bed after taping it into place using the pins to orient the board.

The board is wider than the cutting volume of my bit, so I flipped the board over after cutting as much as I could and then used a hand saw to cut the tab off afterword's. This has the added benefit of allowing me to install the board in either direction, giving me two straight surfaces to wear out.

It seems to be working quite well. I have not taken the time to cut my piece out, but I am all ready to do it whenever I work up the nerve.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.