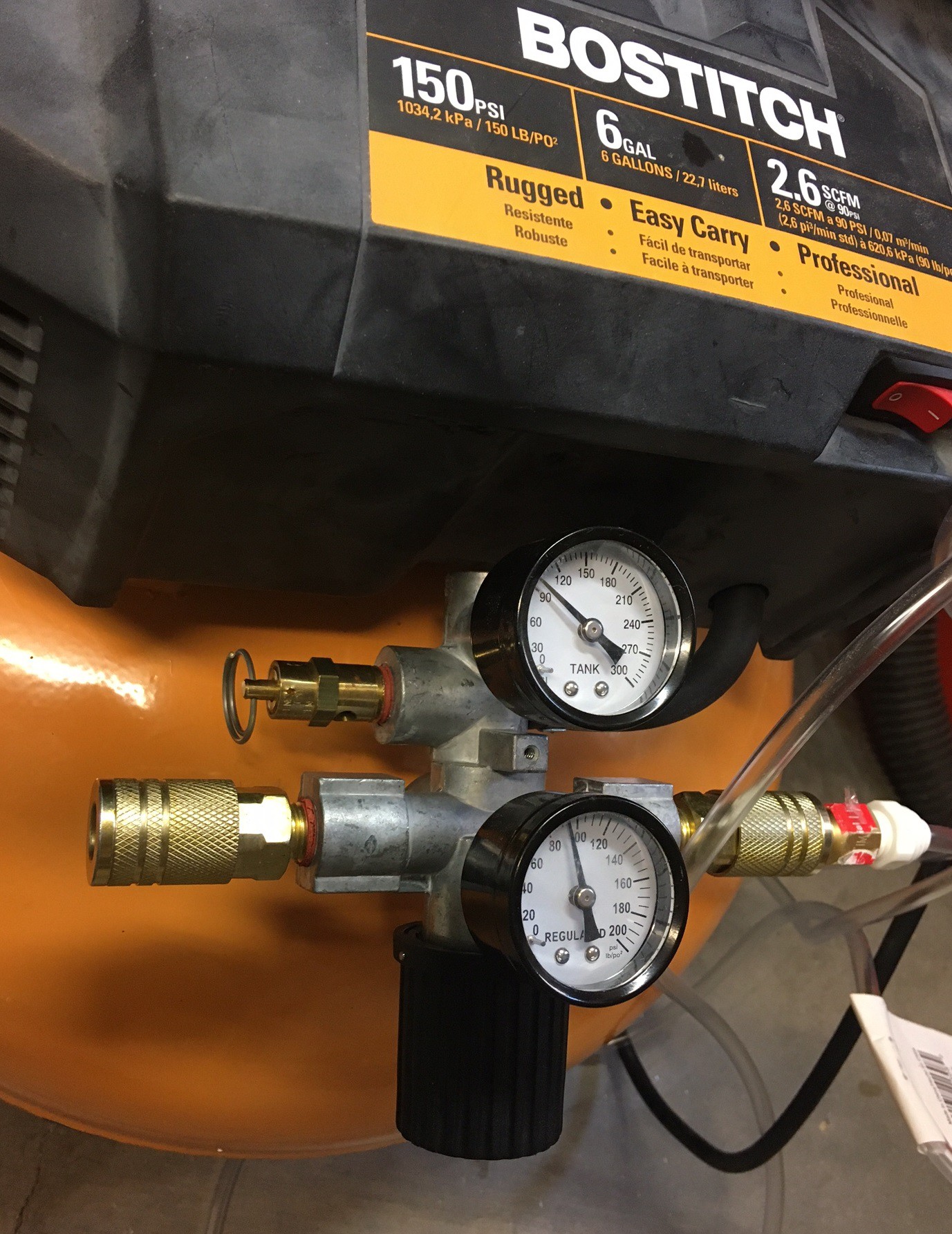

So the pressure regulator on my Bostitch compressor has never worked well. It tends to jump all over the place both when adjusting the pressure and when starting and stopping the flow of air. I would try to dial it in to 30 psi, but when I turned on the air the regulator would completely close up and stop all air flow. So I would dial it back up to 30 psi with the air running and when I then shut the air off the regulator would jump to 50 psi. Even worse turning the air back on may give me 40 psi or 20, it was all over the place.

So I took my regulator apart to have a look at it. It is a massive all in one unit with both gauges, pressure relief valve, and the inlet and outlets all connected into one monolithic cast piece. There is no way to replace just the regulator. On top of that you can only strip it down so far, the poppet valve and spring are press fit into the housing and it is made of plastic so I was unwilling to try and wrestle it apart.

This is a piston style regulator, rather than a diaphragm style. That means as the air pressure changes on the outlet side we have to mechanically move a piston back and forth in order for the pressure to regulate. The piston looked ok but it was a bit dry so I wiped everything down and re-greased it all and put it back together. That seemed to help a bit, now the regulator reacts much quicker when I turn the adjustment knob (previously It would take a full turn of the knob before the needle moved). However it still has a 20 psi swing to it when letting the air flow. On top of that it is not very reliable at the low pressures we would like (5-30 psi).

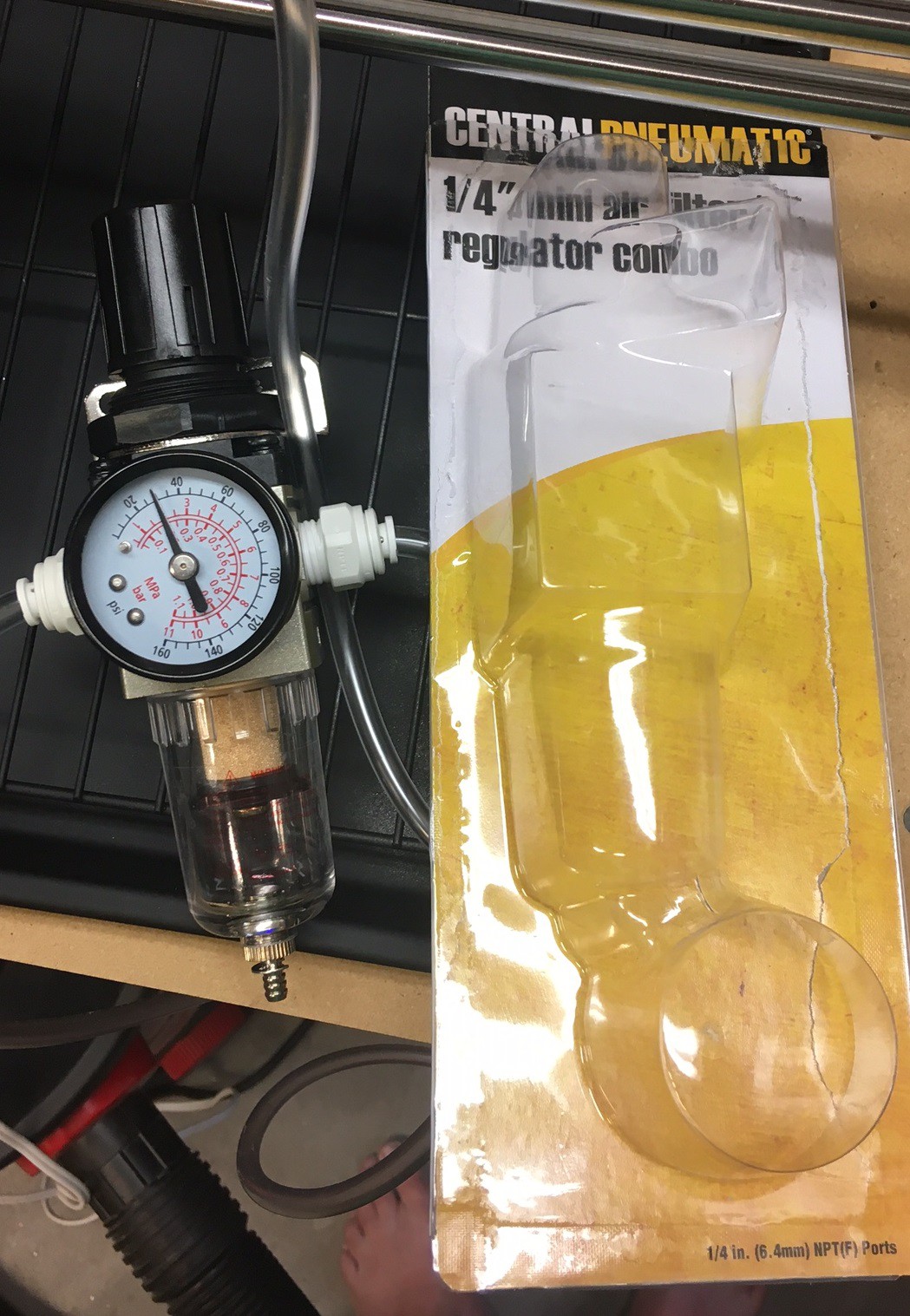

So I swung buy Harbor Freight and picked up a 1/4" air line filter and regulator for $15. This uses a diaphragm rather than a piston and has a lower psi range (5-120 psi). This is working really well, I opened up the regulator on the compressor to 90 psi and set this to 30 psi and it is only dropping 2.5 psi when I let the air flow through my nozzle. Interestingly the regulator on the compressor is still dropping 20 psi, but fortunately it is not affecting things down stream.

This should help a lot with precisely controlling the air flow going forward. It also has an air filter (of sorts) and acts as a water separator as well so that is a nice bonus. The air here is really dry so water is not much of an issue, but we do get humidity for a month or two. Anyway I'm looking forward to getting to really test this out soon.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.