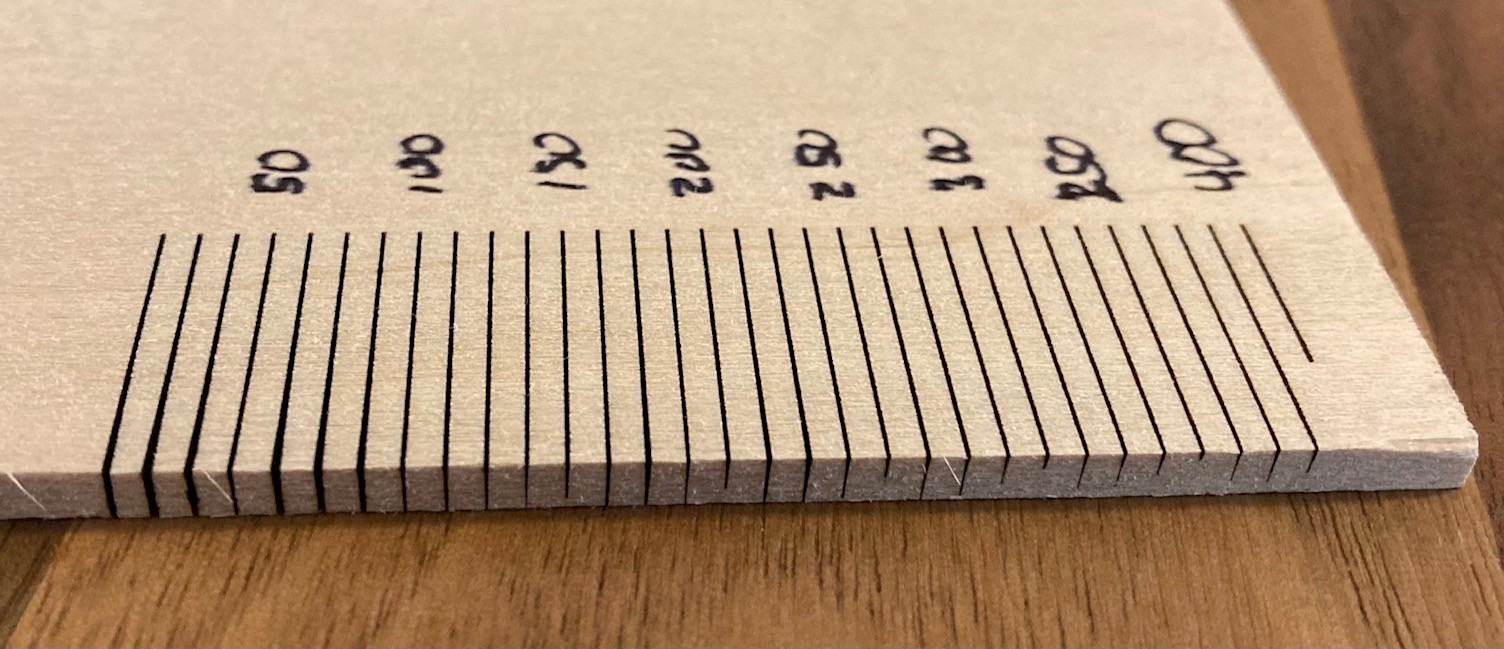

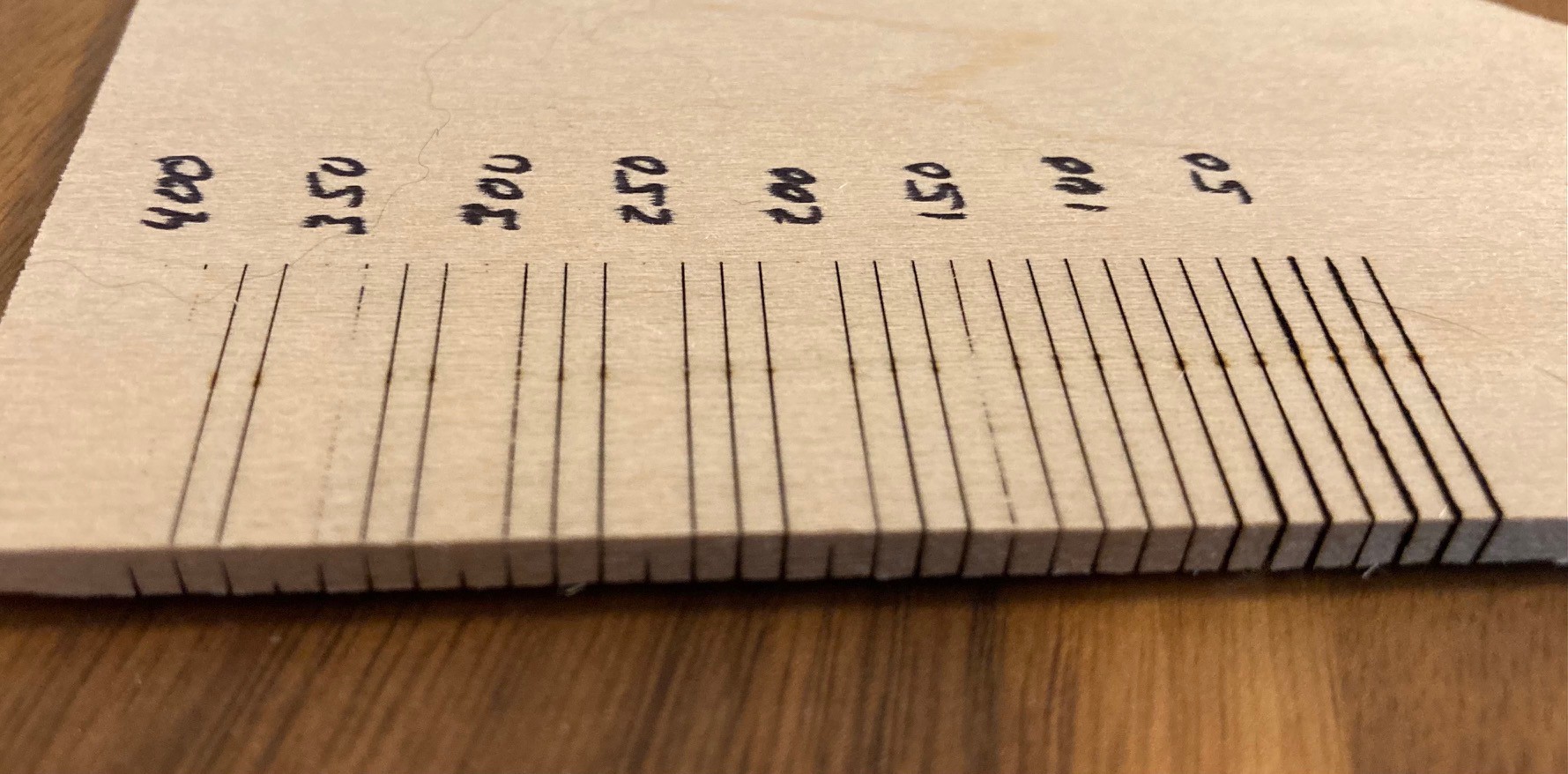

So I ran my test program on a piece of 1/8" (3 mm) balsa wood and a piece of 1/4" (6 mm) balsa wood. I used my 30 w NEJE laser (7.5w optical power) at 80%, with speeds from 50-400 mm/min and 1-4 passes at each speed.

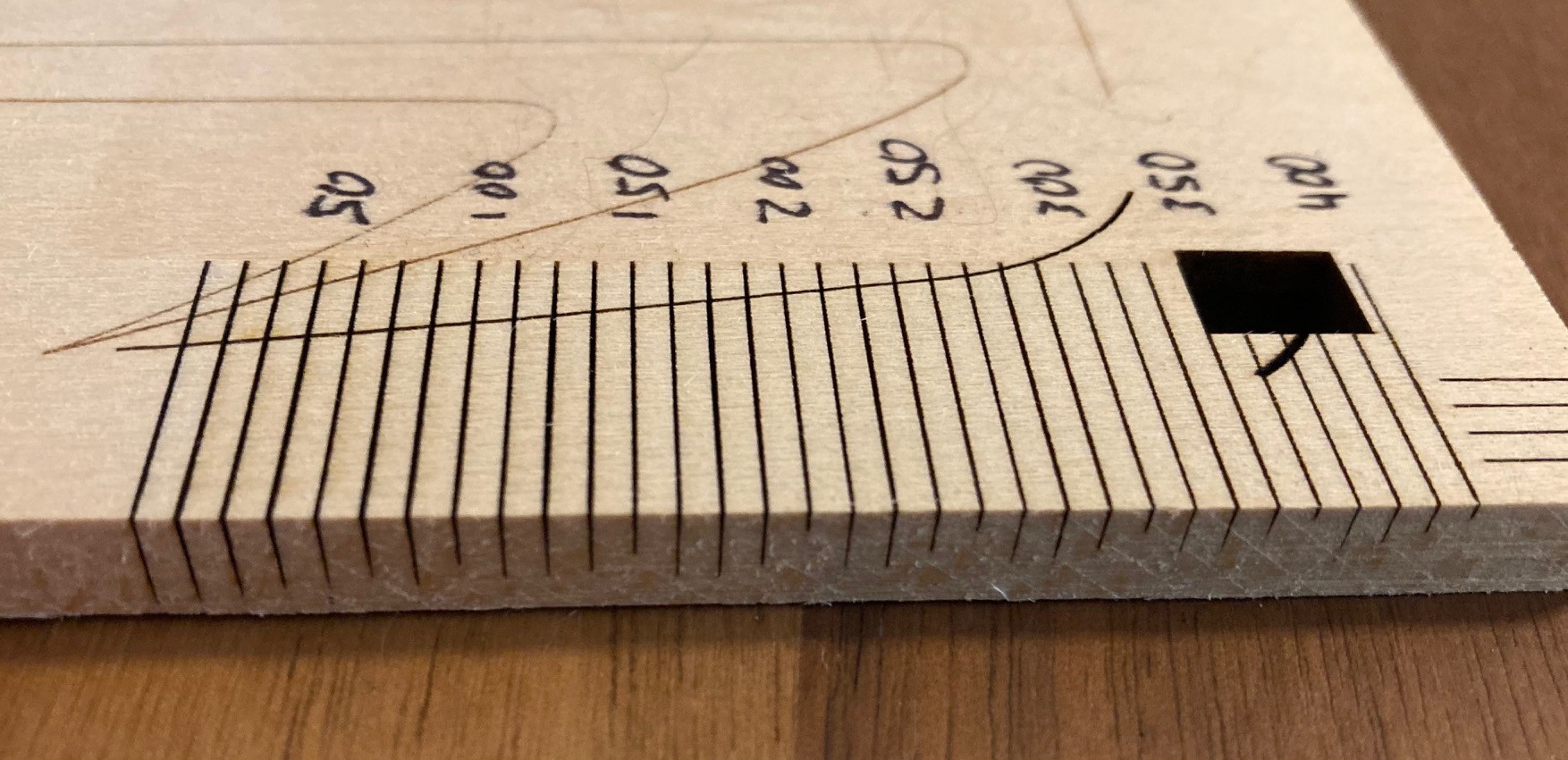

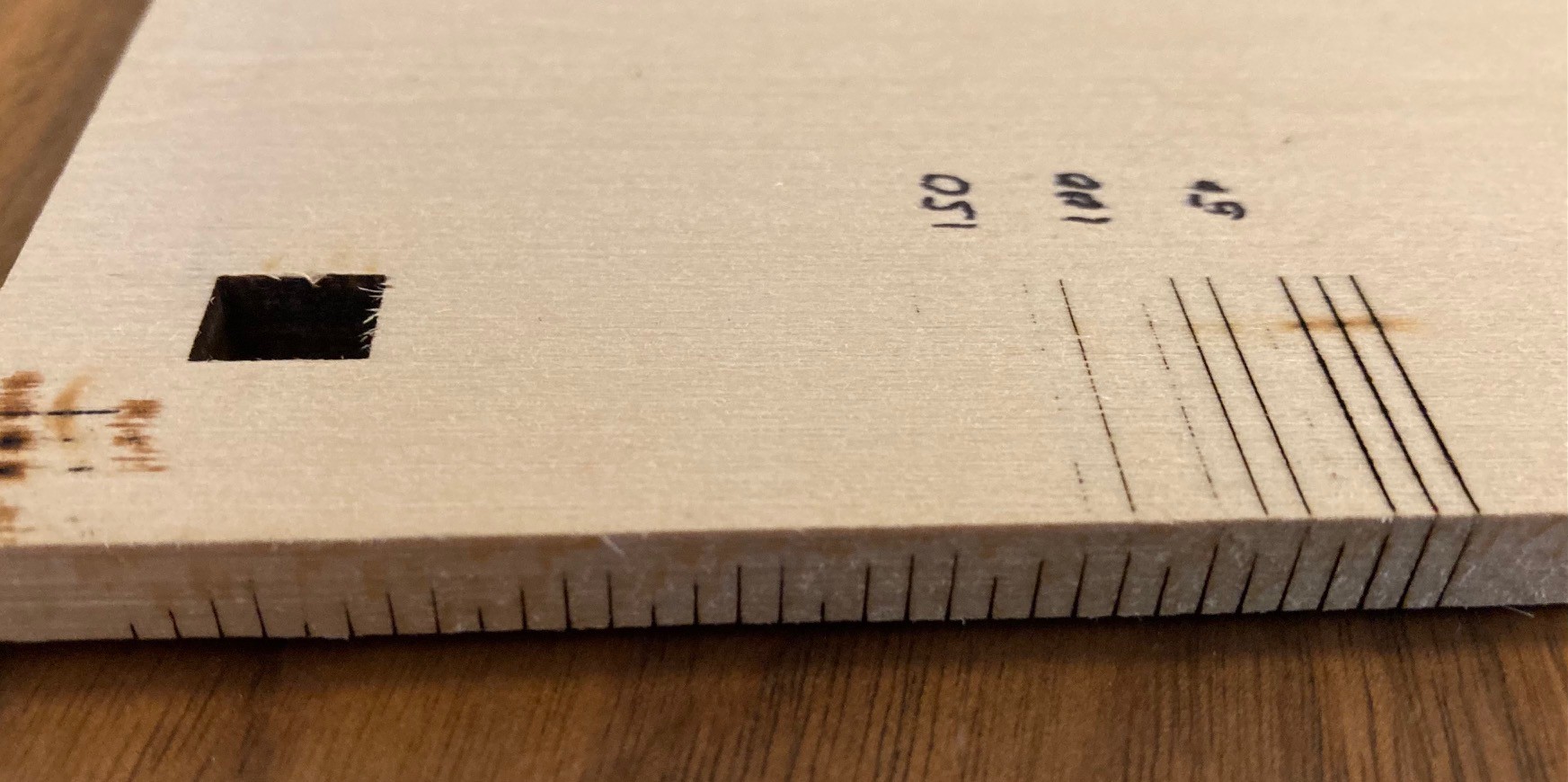

The thinner piece was basically cut through cleanly at almost all speed and pass combinations except for a few of the fastest single pass speeds. That limits what we can get out of this test, however it is interesting to see how much extra damage is done to the wood when cutting at the slowest speeds.

On the thicker piece of wood only a few passes managed to cut all the way through, and that only at the slowest cutting speeds did we make it through the wood. Only 50 mm/min managed to come close to cutting through the wood in one pass, and even then we would need to turn it down a bit more to guarantee a clean cut. It took two passes at 50 mm/min (52 seconds), 3 passes at 100 mm/min (41 seconds) to get through cleanly. With 4 passes at 150 mm/min (39 seconds) almost got through but we would need to slow it down a bit to get all the way through and chances are that would loose any benefits. In this case going faster with more passes seems to be giving some benefit to the cut time, but not a dramatic benefit.

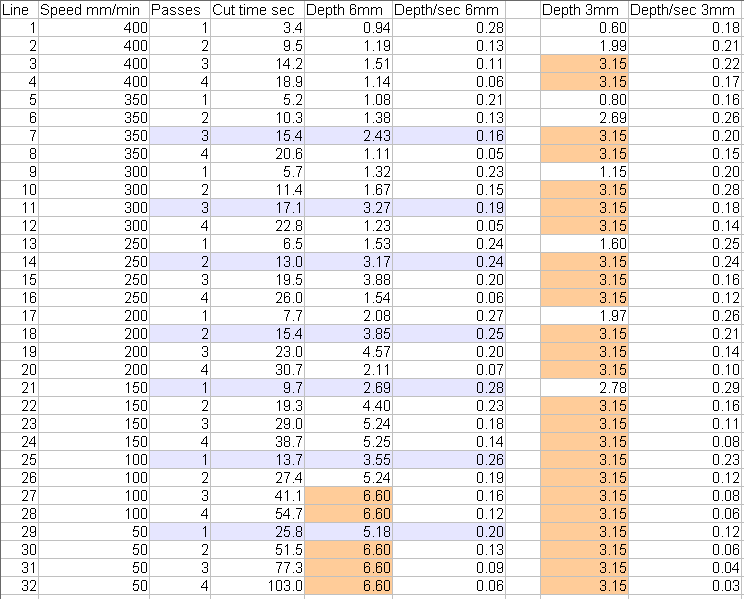

I measured all the depths of cut and put them in the below chart, at the same time I recorded the time the actual cut took (minus any transit time between the passes), and finally I calculated a cut depth per second metric that may or may not have much value.

Depths marked in the orange (salmon?) color were clean through cuts. For the 3mm wood we can see that the fastest single pass through cut was 100 mm/min at 14 seconds, while the fastest through cut was 11 seconds at 300 mm/min and two passes. That is not a huge improvement but it shows you that there is some benefit to multiple passes, especially as we push the speed low enough that we start to damage the wood.

The blue (grey?) lines represent the quickest cuts at each speed that managed to make a cut deeper than 2.4 mm (an arbitrary depth). The numbers are all over the place because we are not cutting the same depth in each case, but you can see that the fastest cut was one pass at 150 mm/min (10 seconds) , with two passes at 250 mm/min (13 seconds) in second place. Clearly if you can make it through in one pass at 150 mm/min then there is no advantage to going even slower, and we see this with 50 mm/min being almost 3x slower than 150 mm/min. The interesting thing is that adding extra passes doubles the time and it is probably not the optimal way to tune cutting depth, better to tweak speeds so you can make the cut in one or two passes than trying to make it happen with 4 passes.

Once again I'm seeing a loss of performance when making 4 passes on a cut. I can't explain how 3 passes can cut deeper than 4 passes. Either the laser diode is overheating and loosing performance, or there is some sort of buildup of charred material on the 4th pass that is plugging up the kerf and skewing the measurements. I'm thinking of adding a temp sensor to the laser and doing a series of identical lines in some material to see if we can see a loss of performance and/or a build up of temperature.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.