So I have been working through some different ideas on a more streamlined tailstock. I modeled up a new tailstock in plastic that was just a slimmed down version of the previous one. It would work but I still don't like the idea of plastic threads and want to avoid them as much as possible.

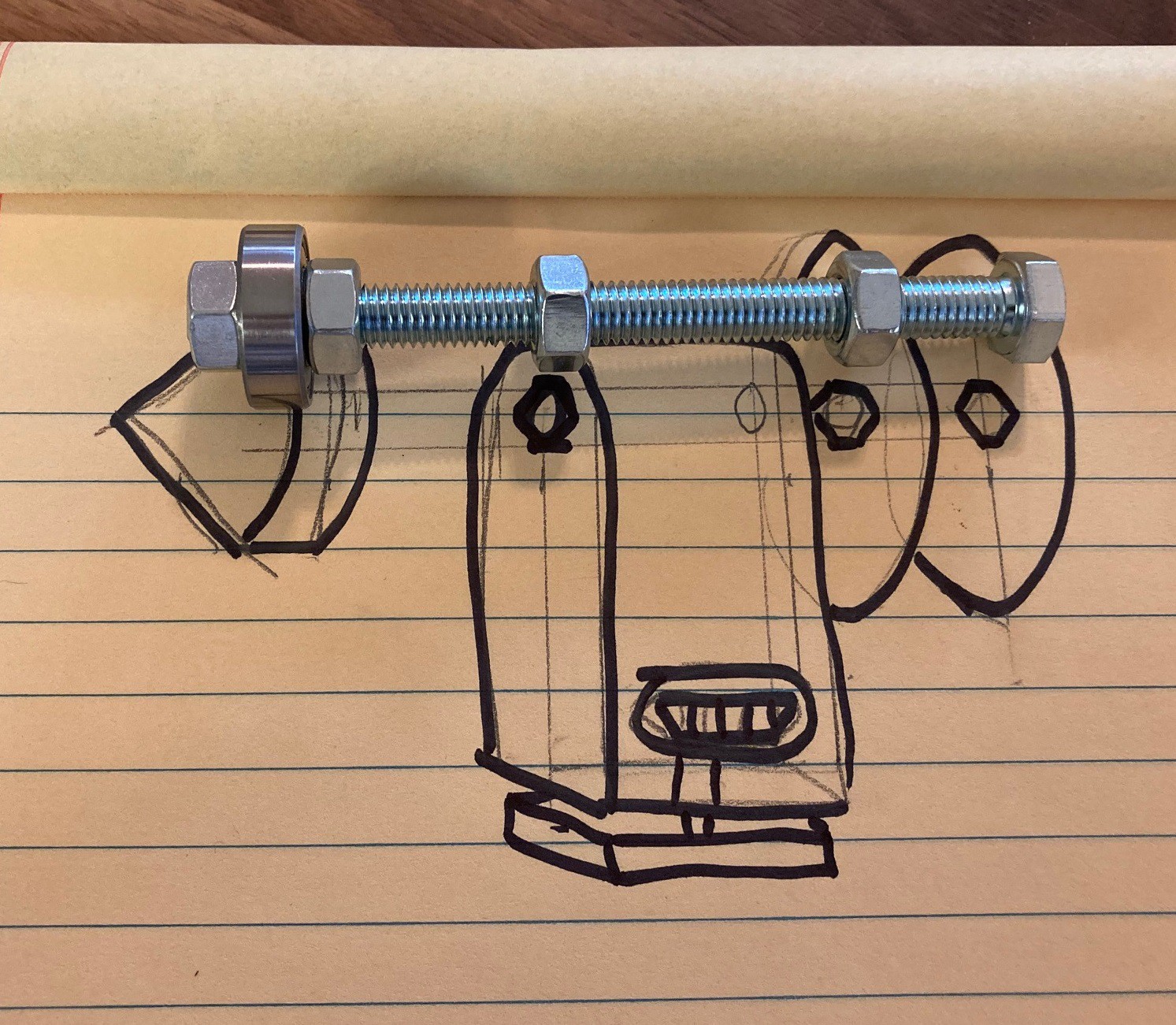

So I swung by the hardware store and picked up a 100 mm long M8 bolt and some nuts and came up with the mockup above. The idea is that we mount the end of the bolt and one nut in to some hand wheels to let us set the quill and lock it into place. Then using another nut in the base allong with a snug 3D printed bearing to act as the guide to hold the shaft stable. Finally making a captive bearing at the front to act as our quill.

The bearing at the front bugs me, it is overkill but I can't see a good way to captivate the bearing in plastic and still have a solid coupling that won't wobble around quite a bit.

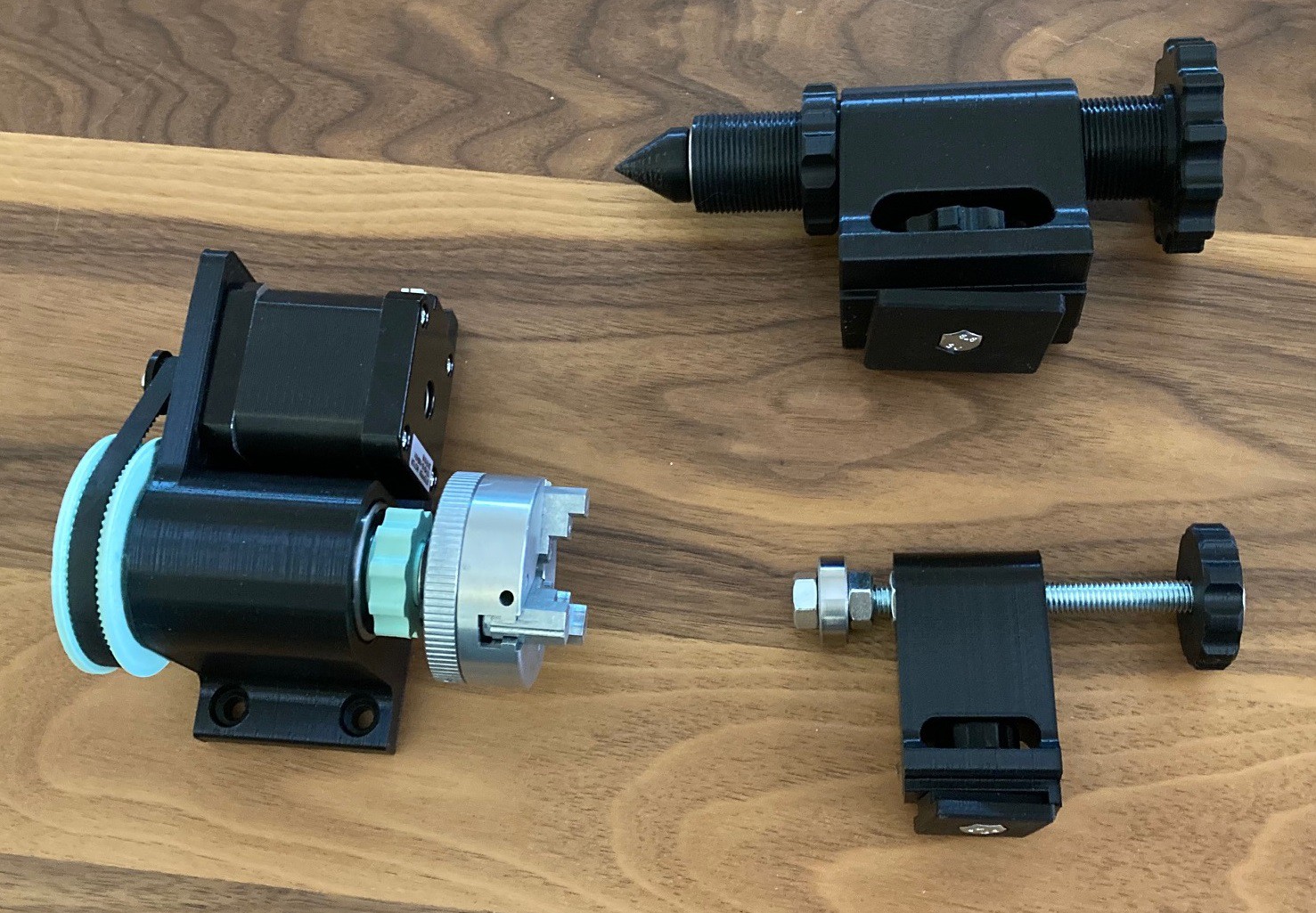

Anyway a little modeling, and waiting for a print and I get the mockup you see above. I need to add a second wheel to it to lock it in place and come up with the end of the quill. I would like the quill to be modular but I don't see a good way to do that with this setup.

Maybe I need to flip things around and put the bearings in the base block and use the wheels to set the length of the rod. That way the whole rod can spin freely so the quill can just thread directly onto the rod. It is something to experiment with.

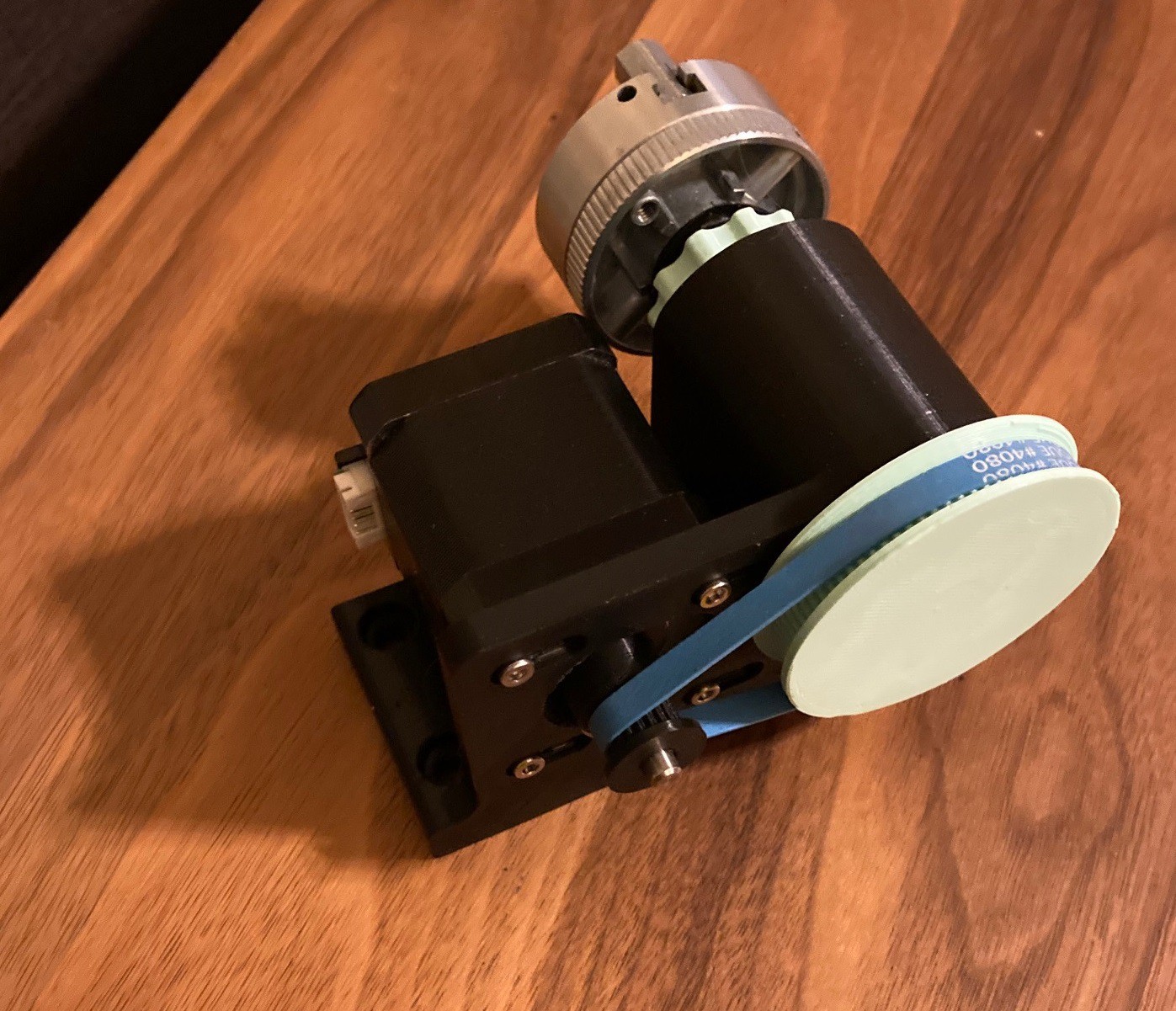

Finally as a test I took a small rubber band from a bunch of asparagus and tried that out in place of the timing belt on my 4th axis. This works, but just barely, it may be a good temporary solution while you wait on parts but I don't recommend using it this way for long. The rubber band is super springy so if you move the motor to fast you get overshoot, it also has a poor grip on the pully's. It is possible a thicker or smaller rubber band would work better, but I don't think it would be a big enough win to justify skipping buying a belt.

Now if you can't get a belt for some reason, then this may work ok for use with a laser, but never with a spindle.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.