So my MKS Gen L v2.1 board came in yesterday. I also picked up some Triaminic TMC2209 drivers, and a small 4 line LCD panel with rotary knob and a SD card slot. The 2209 drivers are just for fun. I was curious to experiment with sensorless homing. The LCD is not supported in GRBL but I thought I would get it to play around with Marlin or some other firmware.

As for firmware, this board is essentially the last incarnation of a RAMPS board and so it can run GRBL-Mega, however that unfortunately has not been well maintained and is not on the latest version of GRBL (it is on 1.1f and not 1.1h) and we need the latest version in order to support auto squaring of our dual y axis motors. There is a rumor that GRBL-Mega-5X supports auto squaring, although I have not been able to find any documentation on this yet. It certainly did not port it over straight from GRBL 1.1h, but may have recreated it on there own. This is in active development, so that is a plus at least.

The other board I ordered is a 32 bit board so it can't run any of these. However there are some other options worth exploring. There is GRBL-HAL that is suppose to be a more modern version of GRBL with support for lots of hardware. Unfortunately it does not seem to support any 8 bit boards, but you can't have it all. It seems to be in active development like the Mega-5x fork. There are a few other GRBL ports out there, but they seem to either focus in on one board or are not well maintained.

Moving on to Marlin you can still find 1.1.9 somewhere out there and that runs comfortably on any 8 bit arduino clone. However Marlin 2.x seems to support the Mega very well and so that is probably a better code base for starters, it also supports any 32 bit board you can think of, and has a well optimized post processor. The big win for Marlin is that it is very well supported (much better than GRBL or any of its forks), it has full support for running off of a SD card, full support for LCD displays, rotary knobs, and touch screens, and it has a very rich set of supporting software such as OctoPrint. Finally it appears to support all the things we do like about GRBL such as laser mode, auto squaring and reasonable jog support. And of course it supports 5 axis. I will need to experiment with it for a while to see if it is a seamless replacement for GRBL or if all my other tools will need to change to support it.

---

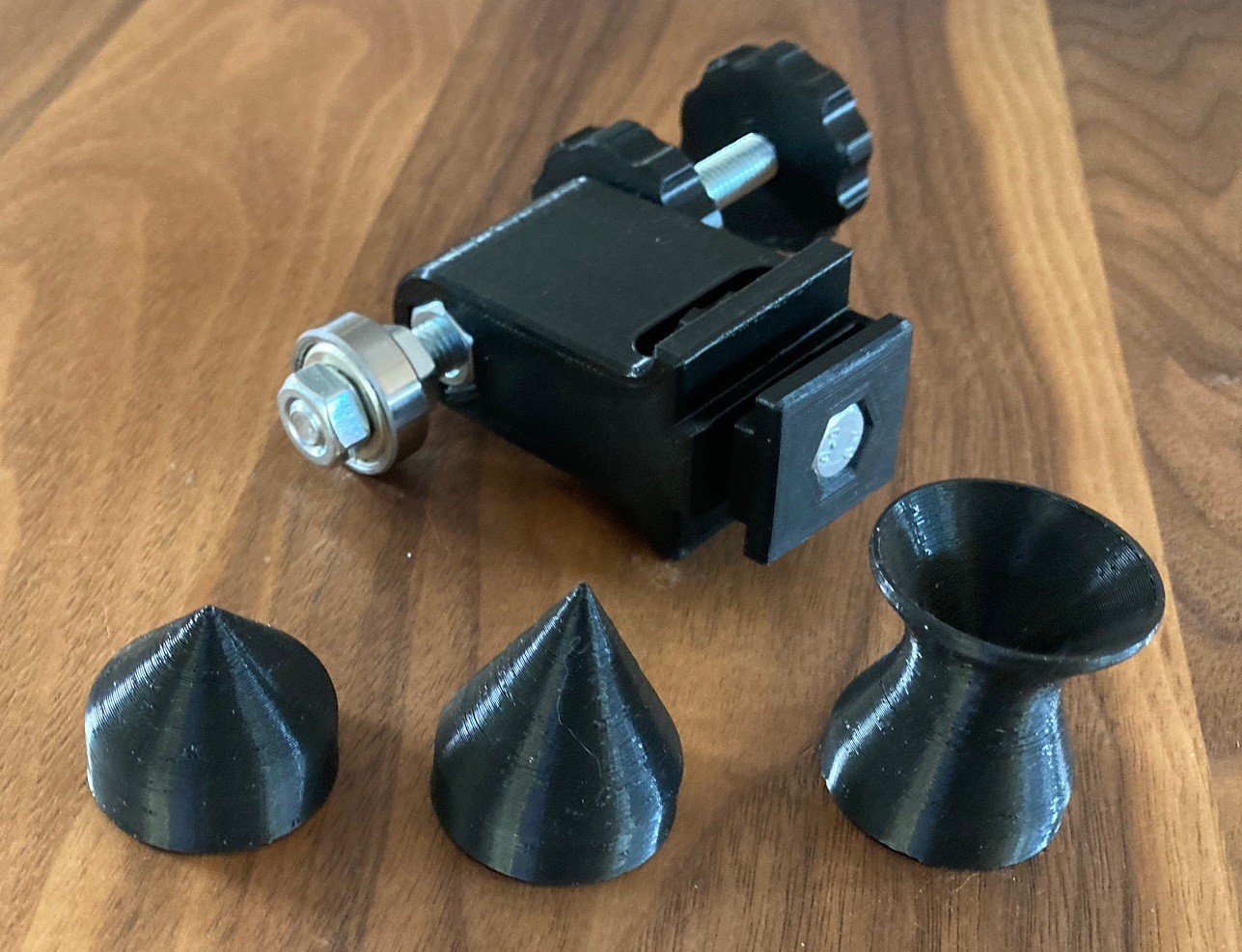

My new quill's came out great. I'm loving the idea of printing them a bit snug and heating them with a hair dryer to get a perfect fit. I don't know that the angles are right on the egg cup shaped one, but it is a start. I will need to find something round that needs machining, although honestly I had nothing in mind when I made it. It is just to prove that this idea could do more than just support pointy tips.

The bearing I'm using has a bit of play in it, and that gets translated to the quill. So far that is the only point of noticeable flex or movement in the whole system. I will need to wait till after my base board is machined to see if the foot can actually hold the whole thing stable. Maybe if that is solid I will look into buying a better quality bearing for the quill.

On the base side of things. I designed it larger than my working area so I will need to tile it. I thought about drilling some holes for pins and doing this up fancy but I decided to go in a different direction. Instead I'm going to make a replaceable straight edge that can be added to the left hand side of the spoiler board. Then I'm going to use the machine itself to mill that face smooth so I know it is perfectly aligned to the Y axis. That will allow me to move my piece down with precision when it is time to tile. I will need to come up with some way to mark and move it the exact right amount in the Y direction, I suspect a few pencil marks will do just fine for this, being off by a half mm in the middle of the cut is unlikely to make a big difference in the final design.

I also need to come up with a new hole pattern for my base board. I placed the hold down's for my spoiler board in a somewhat arbitrary pattern and it does not lend itself well to holding down anything but a full size sheet of wood.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.