I have been hung up on the rotary axis for too long, it is time to reorient before I burn out on this. I will circle back around again and work out a way to drive the rotary axis at a later date. I may even explore writing my own post processor to unwrap and wrap toolpaths.

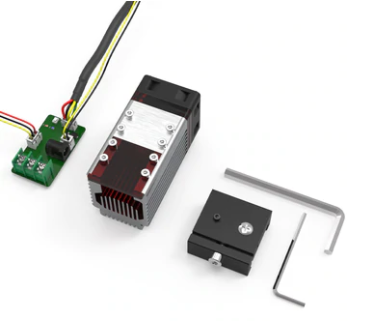

My birthday is coming up soon and I decided to ask for a NEJE A40640 laser module. This cost quite a bit more than the module I have now and honestly I don't need it, it is a total splurge. However the laser has been the most fun I have had with the machine by a longshot. I find it fascinating, and so I want to keep going down that road and see how far you can push a diode laser setup.

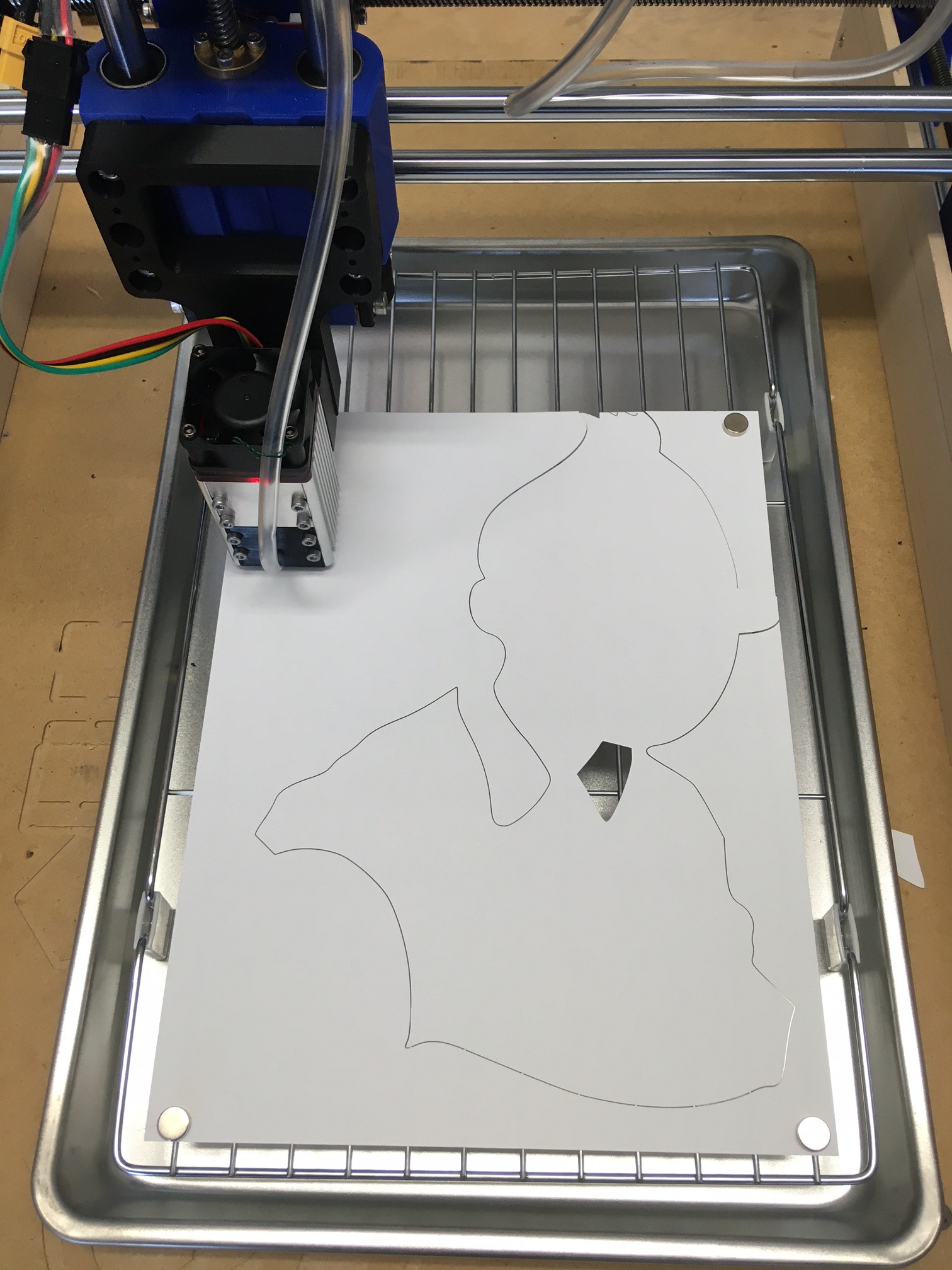

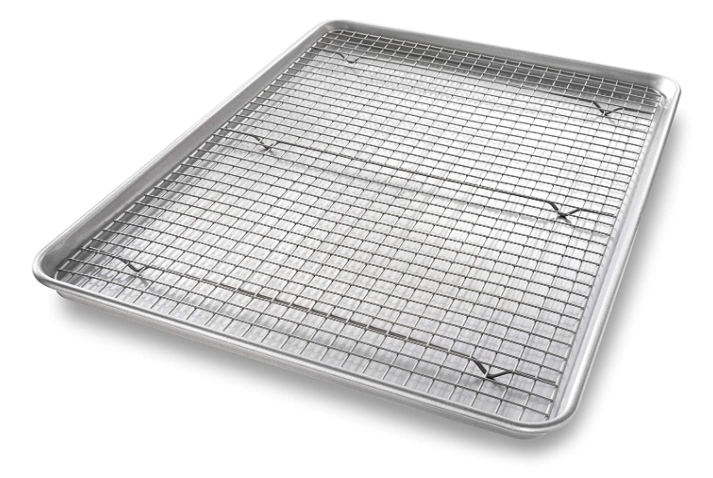

To that end I have been looking really hard at upgrading the laser bed on my machine. I have been using a cheap cookie sheet and cooling rack as a bed but the one I have is small, being a 1/4 size sheet at 9x13 inches. It just barely fits a piece of paper on it, and it has wide parallel bars that I struggle putting magnets on to hold down the paper. On top of that being a cheap rack it is not very level and it has no registration marks or way to reliably line up parts with the laser.

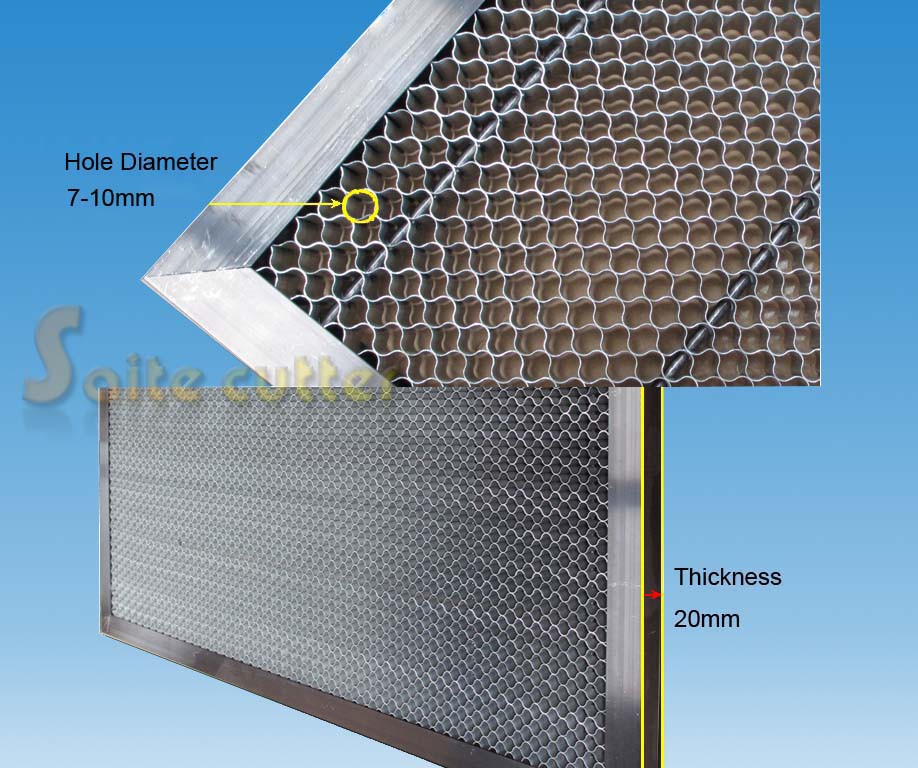

I really want a honeycomb bed. These have an inch of steel honeycomb to support the material, with steel rods running through the honeycomb to support it, and with an aluminum frame around the edge to protect the fragile honeycomb and give it strength. The bed has no bottom, you still need to add a steel or aluminum plate under it to protect the surface of your machine, and you want a gap between the honeycomb and plate so there is plenty of room for air to flow out from under the cut as well. These are expensive to start with and adding that extra material further raises the price. The largest one I could find that would still fit my work volume was a 400x430 mm unit for $70, add in the bed material and it is around $100 plus some effort to put it all together. Plus you loose 50 mm of working volume because of the edges, so you can only use a max material size of 350x380 mm, that is large enough to handle 12" plywood squares, and letter paper, but nothing larger.

That is way outside of my budget for this machine so I have been looking around all over the place for an alternative that is lower cost but almost as good. I ended up settling on using a larger cookie sheet and cooling rack. I found a 3/4 sheet with rack for $35 that is 21x15 inches (534 x 381 mm). My laser can only move 18.5 x 14 inches (470 x 355 mm) so this is larger than my working volume and yet it still fits on the bed of my machine. It also uses a grid pattern rather than parallel bars, that should make it easier to put weights or magnets on top of the piece without falling between the bars. I could save $10 by going down to a 1/2 sized sheet pan at 18 x 13 inches (458 x 331 mm) for $25 but I would loose working volume on both sides, I think spending the extra $10 is justified.

The whole structure is still just not level and sloppy with no registration or repeatability. I'm planning on mounting it to a piece of MDF that can sit on top of my spoiler board and slot into pre-existing holes on the board so it always ends up in the exact same spot. Then I want to add leveling feet to the cooling rack so it is also hard mounted to the board and easily leveled. Finally I want to add a right angle at the lower left corner that is perfectly registered with the laser head. This can all be done with the help of a few 3D printed brackets and some plywood (in theory).

This is a tough call, on the one hand with a bit of work the honeycomb board would be an excellent bed, but on the other hand it is still too small and would be one of the most expensive parts of the whole machine. I think with a bit of work I can overcome the shortcomings of my baking sheet and make a good bed for 1/3 the price.

Here are all the measurements I used when working this all out.

Baking Sheet Sizes

26 x 18 (661 x 458) - full

22 x 16 (559 x 407) - 2/3

21 x 15 (534 x 381) - 2/3 Nordic Ware

20 x 13.5 (508 x 343) - 2/3 cooling rack

18 x 13 (458 x 331) - 1/2

17 x 12 (427 x 300) - 1/2 cooling rack

13 x 9.5 (331 x 242) - 1/4

Material sizes

24 x 12 (610 x 305) - plywood

12 x 12 (305 x 305) - plywood

11 x 8.5 (280 x 216) - letter

14 x 8.5 (356 x 216) - legal

17 x 11 (432 x 280) - ledger or tabloid

Dimensions

24 x 15.75 (610 x 400) - Max bed size

18.5 x 14 (470 x 355) - Max movement

16.75 x 14 (425 x 355) - Max move on bed

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.